BIM in the Pharmaceutical Industry: Innovative Solutions for Design and Construction Optimization

The pharmaceutical industry is one of the most dynamically developing sectors of the global economy. Production processes in this field require strict standards and complex engineering solutions, including handling a wide range of substances, storage systems, and transport. Pharmaceutical facilities typically have highly complex layouts with numerous pipelines and technological equipment, which creates additional challenges for designers.

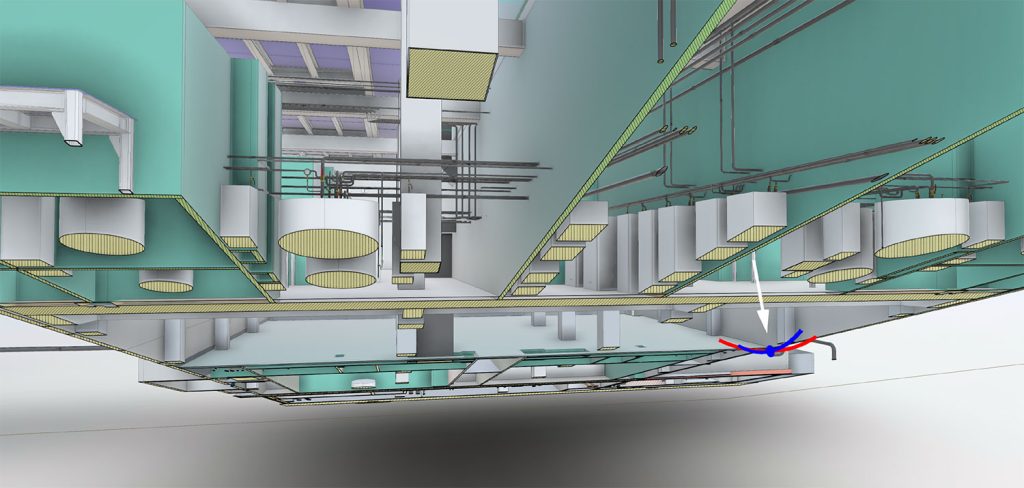

In such densely engineered environments, 2D design often leads to errors and clashes. Mistakes at the design stage can cause significant difficulties during implementation, increasing budgets, delaying project launches, and ultimately leading to financial losses. To accurately determine the spatial position of each component in the production process—be it pipelines, tanks, or other equipment—3D BIM modeling has become an optimal solution.

The Role of BIM in Pharmaceutical Facility Design

BIM (Building Information Modeling) enables the creation of detailed 3D models of production facilities, which helps to avoid clashes during design and minimizes construction errors. One of our company’s recent projects has been to develop BIM models based on 2D documentation for major clients. For instance, “Hidden NDA” company commissioned us to create a 3D model of a pharmaceutical production facility using their initial 2D plans.

Construction Monitoring Using 3D BIM Models

BIM models extend beyond just the design stage; they also play a crucial role in construction monitoring, allowing for real-time oversight of the construction process through portable mobile devices. By using laser scanning technology, construction supervision can also be performed by comparing current point clouds with the digital model. This is especially valuable for investors: without needing to visit the construction site, they can assess project progress, identify potential errors, and make timely decisions on necessary adjustments.

Benefits of Using BIM in the Pharmaceutical Industry

- Reduced errors and clashes at the design stage – through full and accurate 3D visualization of all systems and equipment.

- Optimized budget and project timeline – by preventing errors during design and increasing construction precision.

- Improved construction monitoring efficiency – with the ability to remotely track progress and make quick decisions.

- BIM modeling is becoming an essential element in the modern pharmaceutical industry, addressing design, construction, and management challenges, ultimately improving production quality and profitability.

With the innovative solutions offered by BIM modeling, pharmaceutical projects can reach new levels of accuracy and efficiency. Reducing errors at the design stage, optimizing budgets, and enabling real-time construction monitoring allow companies to meet high-quality standards and respond quickly to industry challenges. BIM not only simplifies project workflows but also significantly enhances profitability—an essential advantage in the highly regulated pharmaceutical industry.

If you’re looking to implement BIM to optimize your projects, ScanM2 is here to support you at every step. We provide 3D modeling, laser scanning, and construction monitoring services to ensure your projects are delivered seamlessly and on time. Contact us to learn how BIM technology can enhance the efficiency and profitability of your business.