How Designers Can Create Perfect Custom Furniture Layouts with Accurate Data

Creating custom furniture layouts involves a harmonious mix of artistic vision, technical expertise, and spatial awareness. Whether it’s a modern, minimalistic living room or a complex office environment with built-in features, every design decision revolves around how well furniture fits the space. Precision is not just a luxury in custom furniture design—it’s essential.

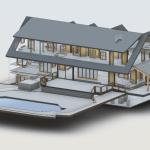

Without accurate measurements and reliable data, the most elegant designs can fall apart during installation. But with the help of 3D modeling and laser scanning, designers can now ensure their layouts are as functional as they are beautiful. So, how does accurate data transform the way designers create? Let’s dive deeper.

Why Accurate Data is Key for Custom Furniture Layouts

Accurate data plays a foundational role in custom furniture design, acting as the blueprint for a project’s success. Imagine planning a set of built-in bookshelves for a historical home where walls may not be perfectly straight. Even a small mistake in measurements can lead to noticeable gaps, misalignment issues, and expensive project delays. Precision transforms the entire process, making sure each element fits seamlessly.

When working with exact data, designers gain several critical advantages:

- Optimal Use of Space: Every inch of available space can be fully utilized when measurements are precise. This is especially valuable for smaller rooms or uniquely shaped spaces where maximizing functionality is crucial. Custom furniture thrives in tight corners, under staircases, or in loft spaces where standard furniture would fall short.

- Error Prevention: Inaccurate measurements often lead to costly mistakes, like pieces being too large or small for the intended space. Reliable data ensures that production and installation happen without modifications, reducing material waste and rework.

- Seamless Integration with Existing Elements: Custom furniture often needs to complement existing features like windows, doors, or architectural details. Accurate data helps designers create layouts where furniture interacts harmoniously with the space rather than conflicting with it.

- Enhanced Aesthetics and Functionality: With reliable data, designers can focus on creating pieces that not only look great but also serve the space’s functional needs. Built-ins, curved surfaces, and unique design elements can be executed confidently without guesswork.

When designers start with precision, the entire process—from concept to installation—flows more smoothly.

3D Data and Furniture Design: A Game-Changer

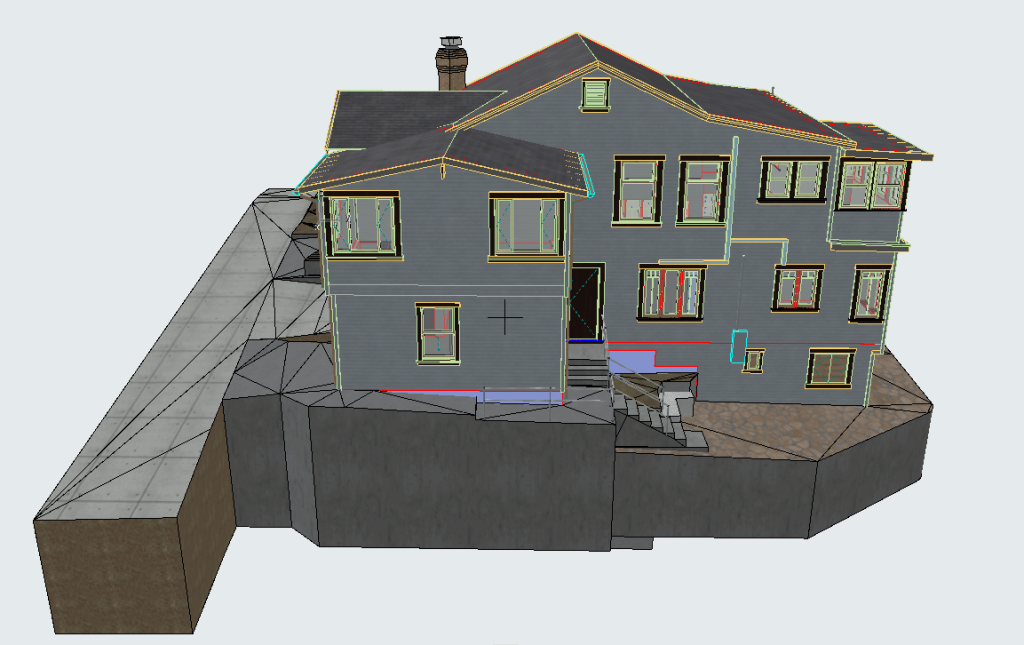

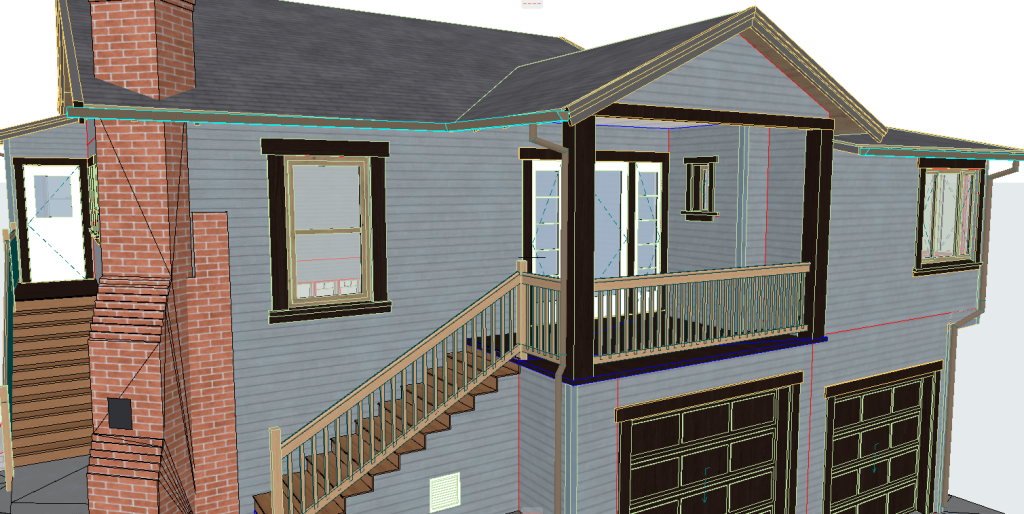

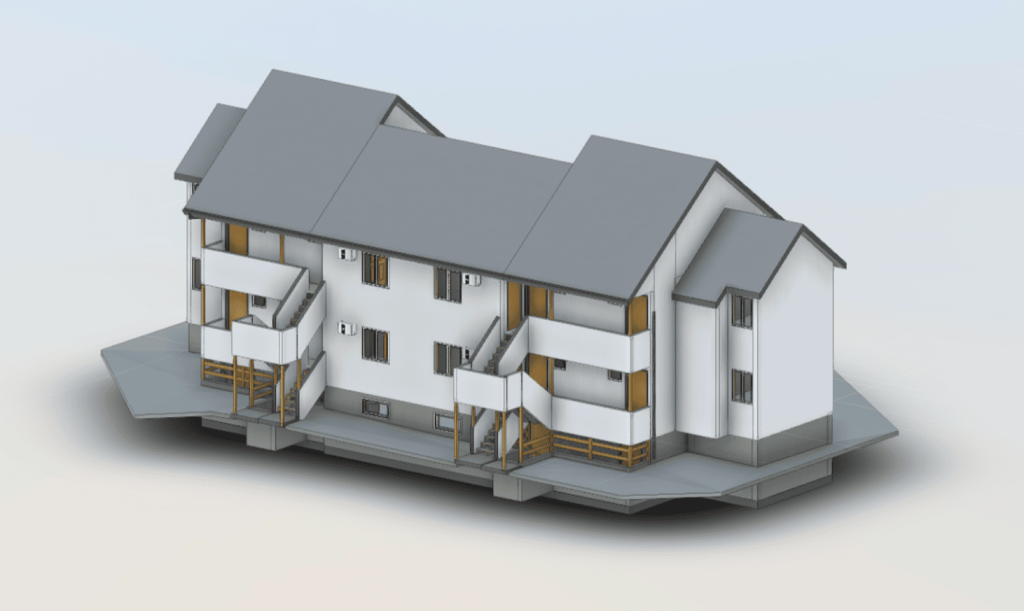

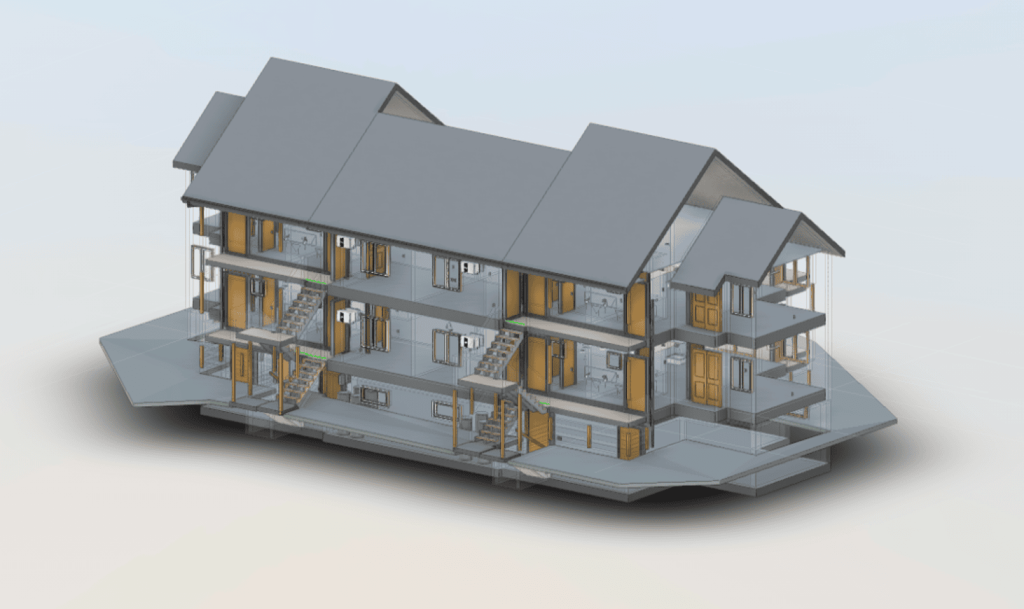

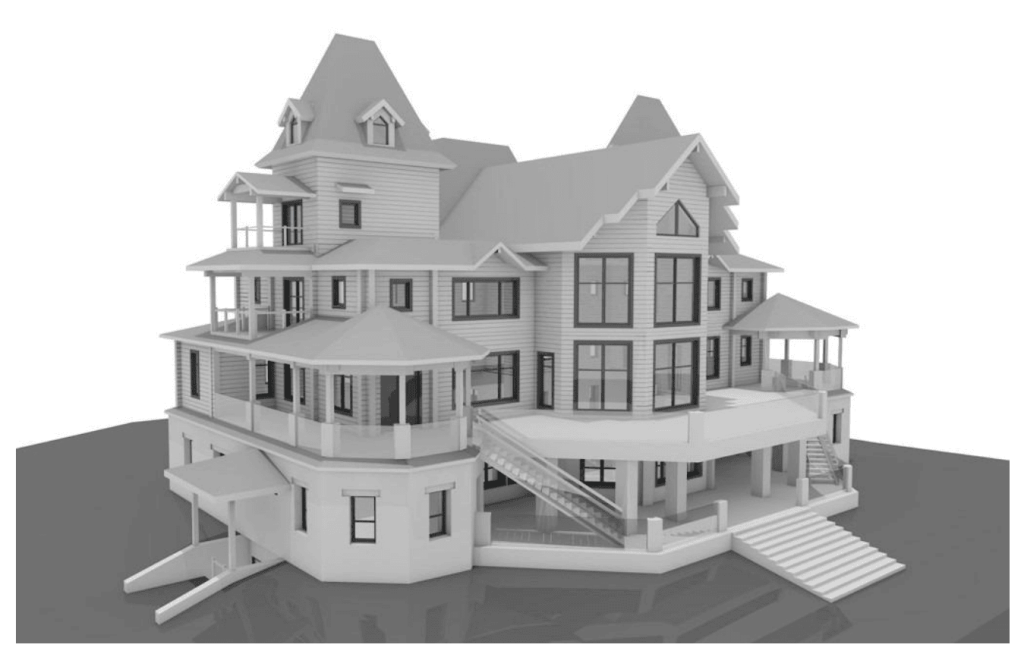

3D scanning and modeling have revolutionized custom furniture design. These technologies don’t just simplify the measurement process—they expand creative possibilities. With laser scanning, designers can capture a space in its entirety, from room dimensions to architectural quirks, ensuring every design choice is based on reality.

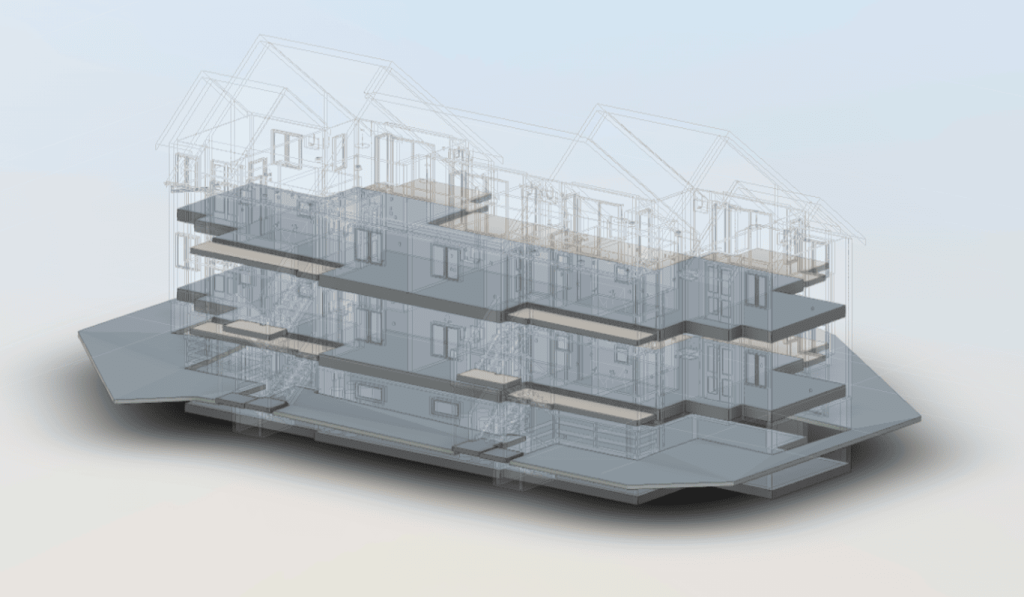

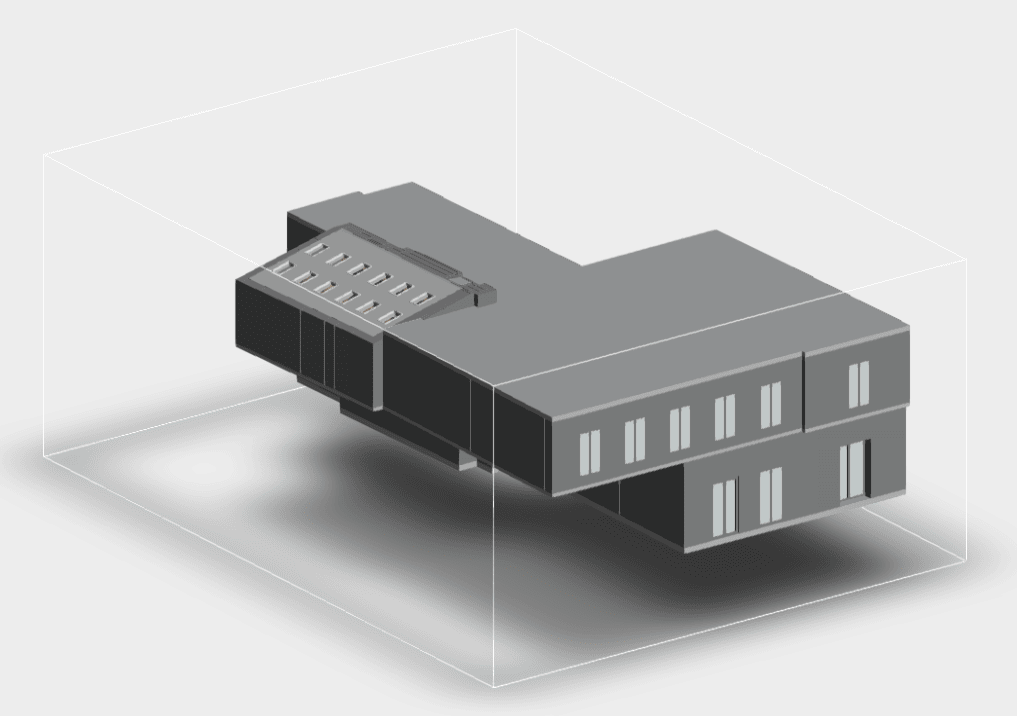

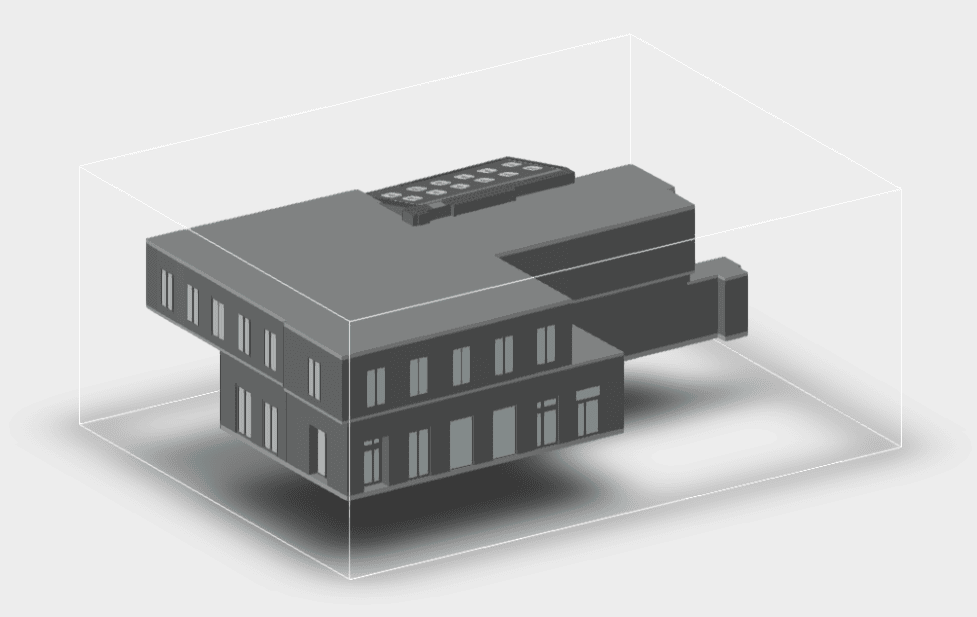

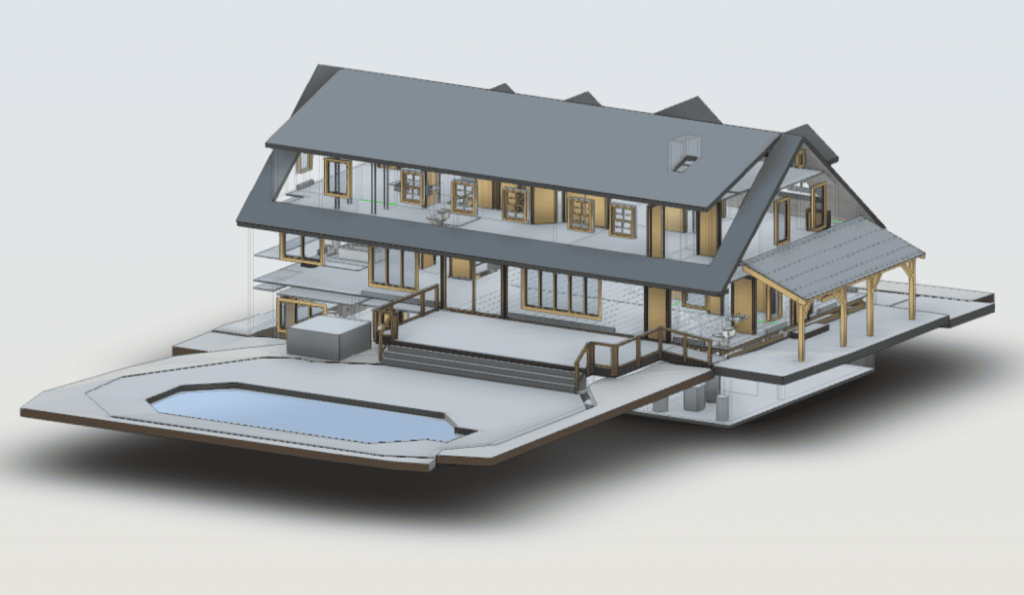

By creating a digital twin of the space, designers can explore creative layouts without physically altering the environment. This opens up opportunities for experimenting with complex forms, asymmetrical furniture, or multi-functional elements with confidence.

Another advantage of 3D data? It enhances collaboration. Clients can view a digital model of their future space, simplifying the communication of design ideas and facilitating early feedback collection. For manufacturers, detailed 3D models ensure production accuracy, reducing the margin of error when bringing the design to life.

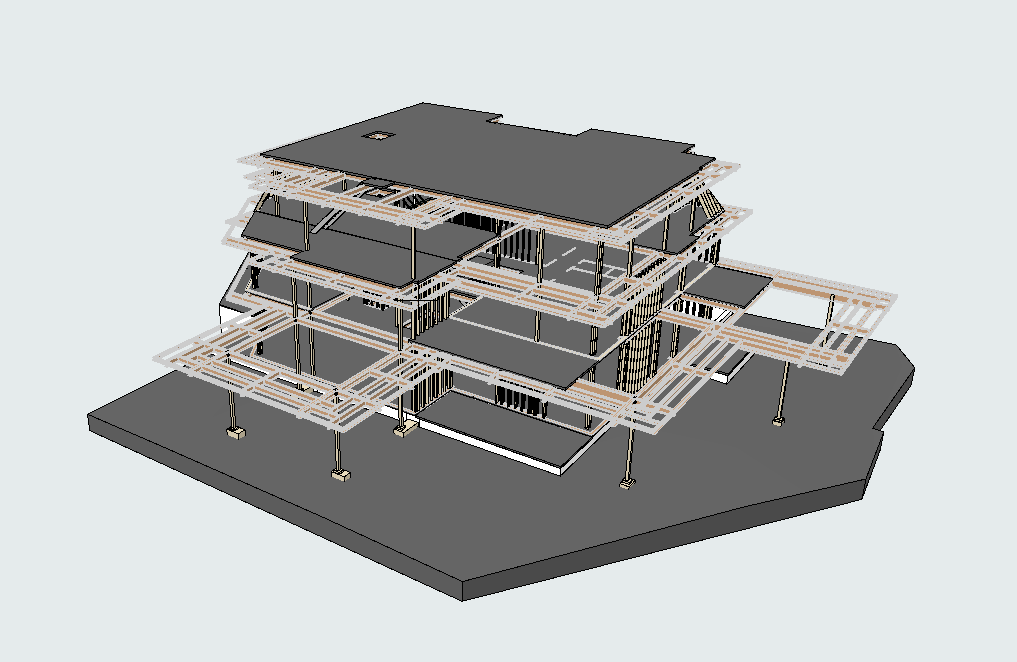

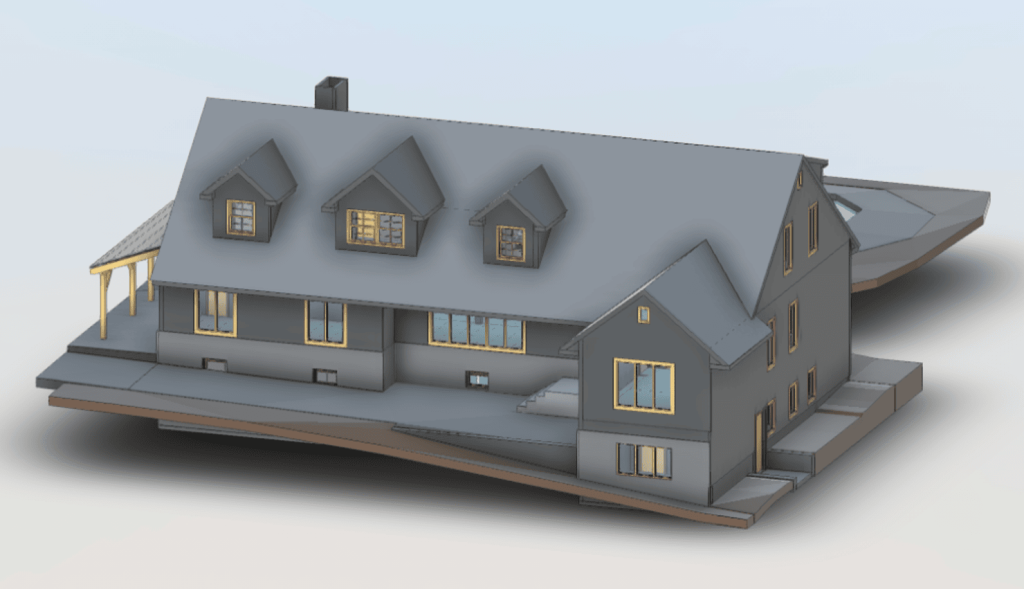

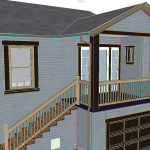

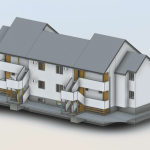

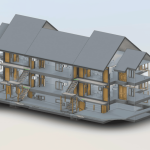

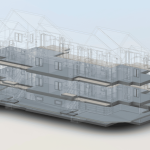

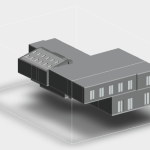

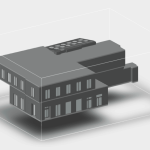

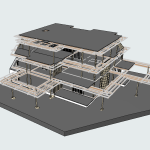

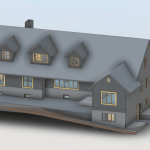

Our 3D Models Examples

Tools That Make Accurate Furniture Layouts Possible

The tools behind modern furniture design have evolved significantly. Today’s technology empowers designers with precision and creative flexibility. Let’s explore the key tools that make this precision possible:

- 3D Laser Scanners:

Laser scanners capture precise room dimensions, mapping out every corner, curve, and structural detail. This is especially useful in spaces with irregular shapes or historic properties where walls and floors may be uneven. The captured data forms the basis for a precise and dependable design workflow. - 3D Modeling Software (BIM and CAD):

Tools such as Revit, AutoCAD, and SketchUp enable designers to convert scanned measurements into detailed digital models. These tools enable detailed modeling of both the space and the furniture itself, helping designers visualize how pieces will interact within the environment. They also support material selection and structural analysis. - Measurement Tools Integrated with 3D Tech:

Some laser scanning tools now come with integrated measurement features, allowing designers to take ultra-precise measurements directly from the scanned data. This removes the necessity for multiple site visits and manual measurements, accelerating the overall design workflow. - 3D Visualization Tools:

Beyond technical modeling, visualization software like Twinmotion or Lumion allows designers to create photorealistic renderings. These renderings help clients envision the finished space with specific materials, textures, and lighting effects. Combining these tools transforms furniture design from a process of estimation to one driven by data and certainty.

3D Floor Plans: The Foundation for Custom Furniture Layouts

3D floor plans go beyond simple visuals—they serve as a functional tool for planning and refining furniture arrangements. Unlike traditional 2D sketches, a 3D floor plan allows designers to explore how furniture will fit and flow within a space before production begins. By using 3D floor plans, designers can:

- Understand Spatial Relationships: Visualize how furniture interacts with doorways, windows, and other elements, ensuring balanced placement.

- Experiment with Layout Variations: Designers can test multiple arrangements within the same digital space, making it easier to compare and refine options.

- Enhance Client Collaboration: Presenting a space in 3D helps clients better understand proportions and design choices, leading to quicker approvals.

For complex projects, such as multi-room layouts or open-concept spaces, 3D floor plans help ensure continuity in design and functionality across the entire project.

The Power of 3D Visualization in Furniture Design

3D visualization goes beyond technical design—it’s about storytelling. It allows both designers and clients to see a space brought to life with realistic textures, lighting, and context before a single piece of furniture is made.

Key Benefits of 3D Visualization Include:

- Enhanced Design Communication: Clients often struggle to visualize how a finished space will look. Lifelike renderings transform abstract ideas into clear visuals, bridging the gap between concept and reality.

- Material and Finish Selection: Designers can showcase different materials, colors, and styles within the same layout, helping clients make informed choices before finalizing the design.

- Eliminating Guesswork: Whether it’s a built-in bookcase or a multi-piece sectional, 3D visualization reveals how furniture fits in relation to other design elements, from flooring to wall colors.

3D visualization doesn’t just help designers—it enhances the entire client experience by turning concepts into compelling visuals.

The Future of Custom Furniture Design Is Data-Driven

Accurate data has become the backbone of modern custom furniture design, ensuring both beauty and precision in every project. By embracing tools like 3D laser scanning, modeling software, and advanced visualization platforms, designers can create furniture layouts that are not only visually stunning but also perfectly tailored to their spaces.

As technology continues to advance, the possibilities for custom furniture will only expand—pushing the boundaries of creativity while maintaining the highest standards of accuracy. Whether you’re designing a built-in wardrobe, a full-room layout, or a unique piece of statement furniture, data-driven design is the key to getting it right the first time.