Laser 3D Scanning vs. Traditional Measuring Tools

When it comes to accurate measurements in construction, architecture, or industrial projects, precision is paramount. For decades, traditional measuring tools such as tape measures and laser rangefinders have been the go-to options for professionals. The advent of laser 3D scanning technology has transformed the industry, delivering a degree of precision and efficiency that traditional tools are unable to achieve.

How Laser Scanning Outperforms Tape Measures and Laser Rangefinders

Traditional tools like tape measures and laser rangefinders have been reliable staples in the construction and engineering industries for years. Although these tools fulfill their intended function, they have built-in limitations that can impede both accuracy and efficiency in contemporary projects.

Comprehensive Coverage

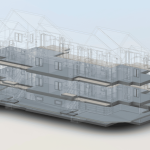

Tape measures and laser rangefinders can only measure single dimensions or distances at a time. This requires multiple measurements and significant manual calculations to create a complete picture. In comparison, laser 3D scanning collects millions of data points within seconds, creating an exceptionally detailed and precise 3D model of the measured object or area.

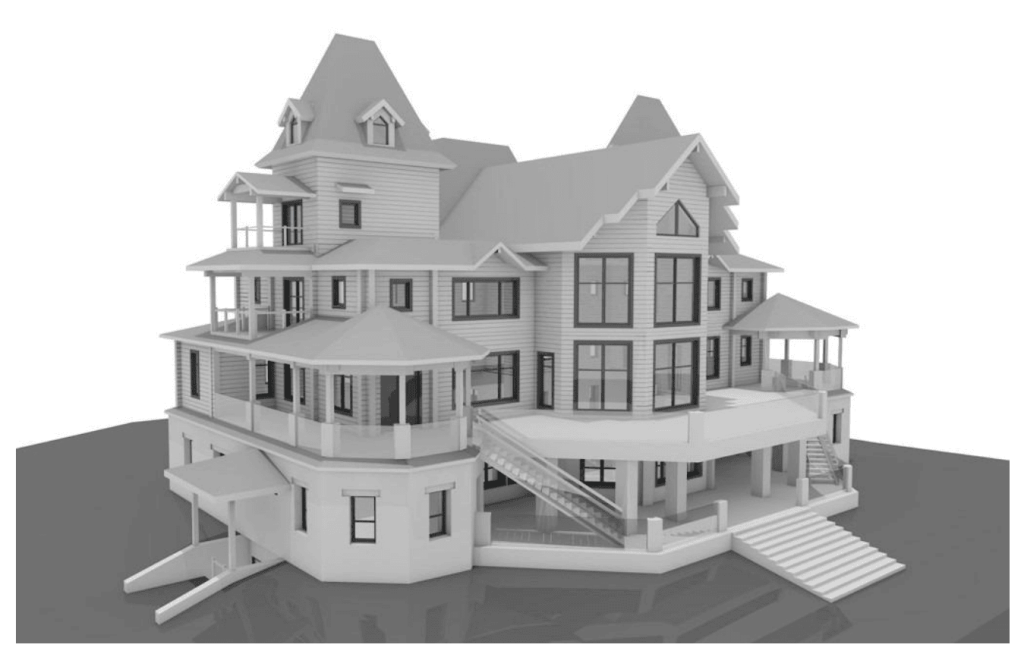

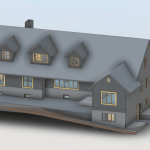

Imagine attempting to map the intricate details of a historical building using traditional tools. The process would be painstakingly slow and prone to errors. Laser scanning technology, however, creates a full digital replica of the structure in minutes, ensuring no detail is overlooked.

Speed and Efficiency

A major benefit of laser 3D scanning lies in its remarkable speed. Traditional tools demand manual labor and often require multiple professionals to achieve precise measurements. In contrast, laser scanning significantly shortens the time required for data collection. For example, a large construction site that might take days to measure using conventional methods can be scanned in just a few hours with laser technology.

This level of efficiency directly leads to cost savings for businesses, helping projects remain on schedule and within their budget constraints.

Enhanced Safety

Measuring large or hard-to-reach areas can be hazardous when using traditional tools. Professionals might need to climb ladders, traverse uneven terrain, or work at significant heights to capture measurements. Laser 3D scanners eliminate these risks by allowing operators to gather data from a safe distance, even in challenging environments.

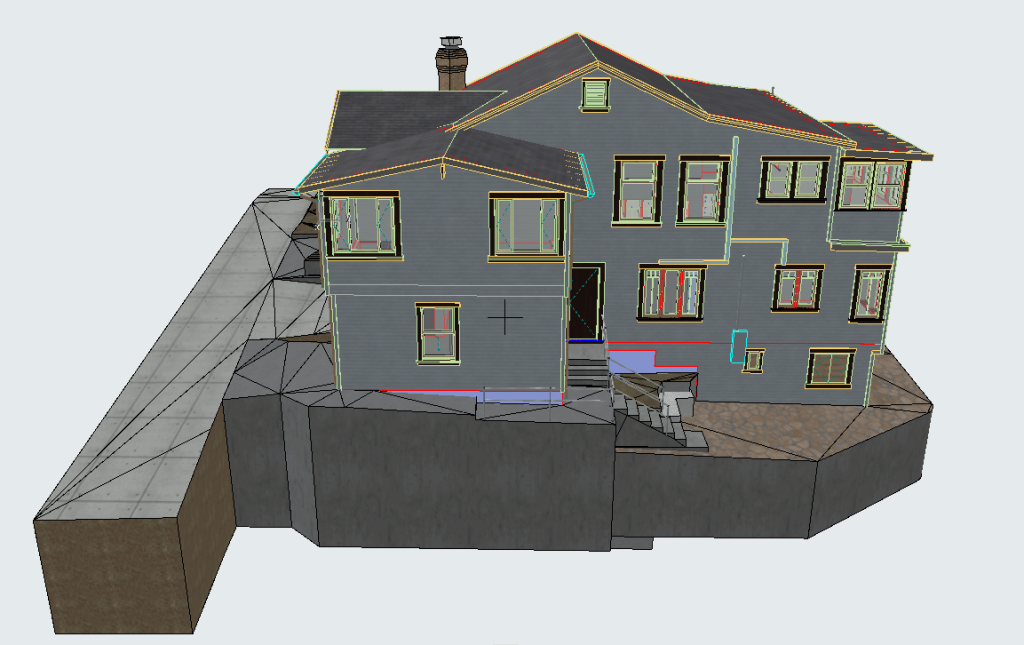

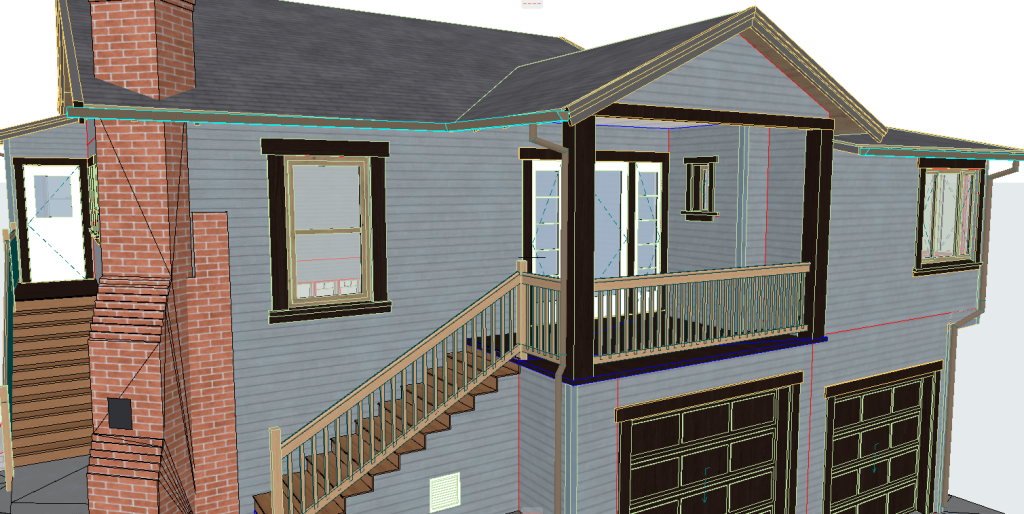

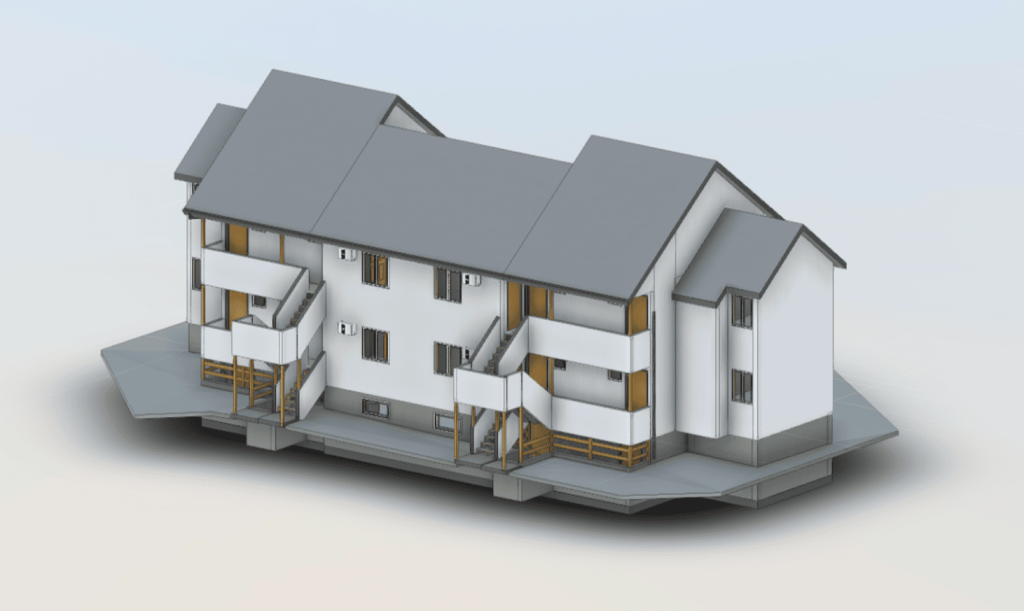

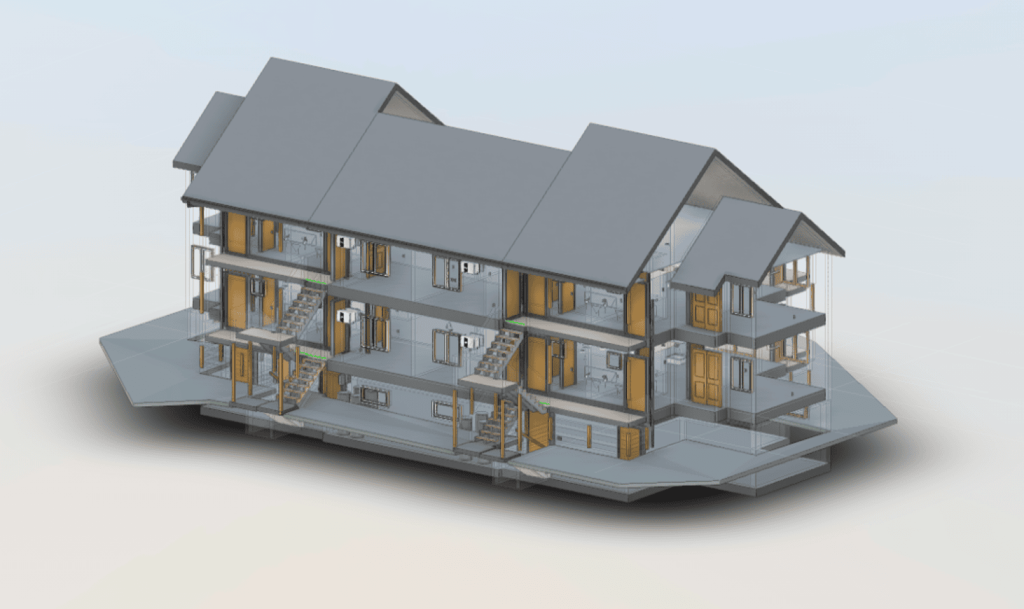

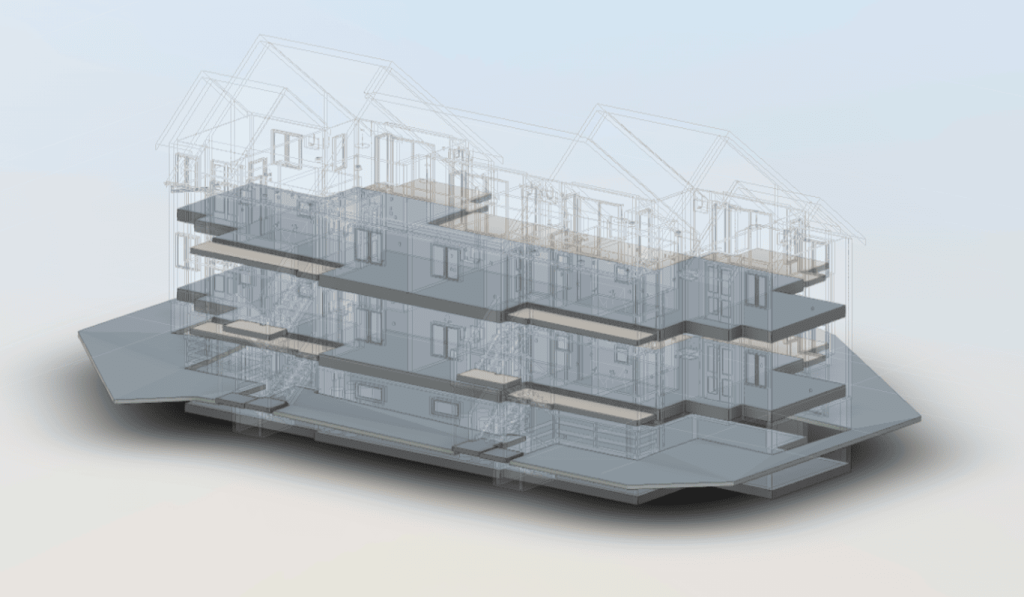

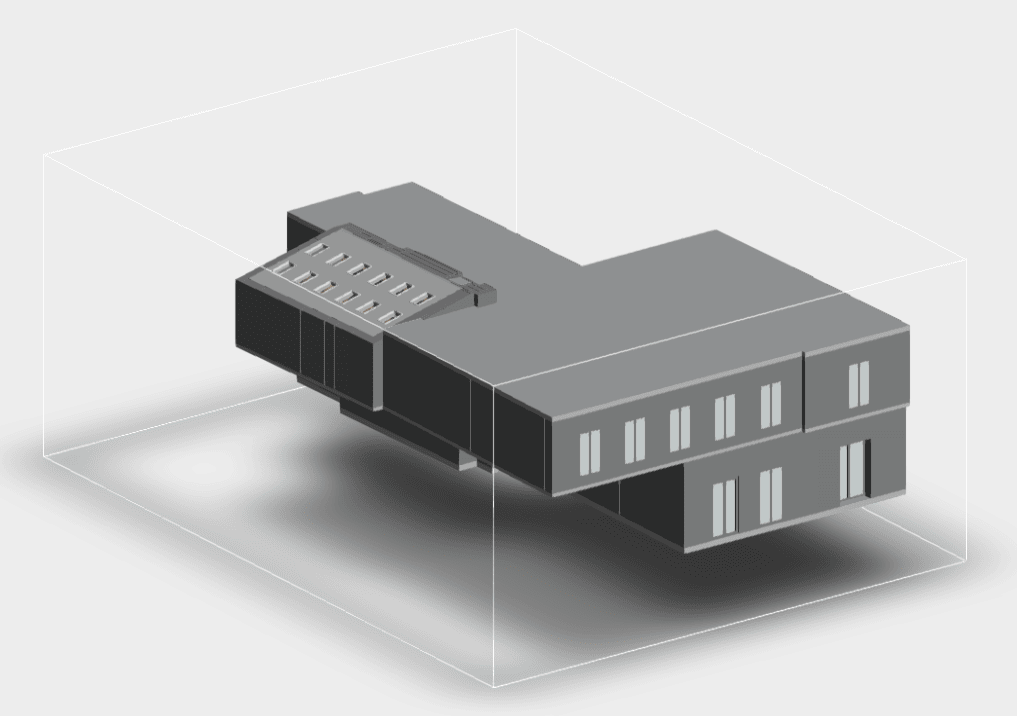

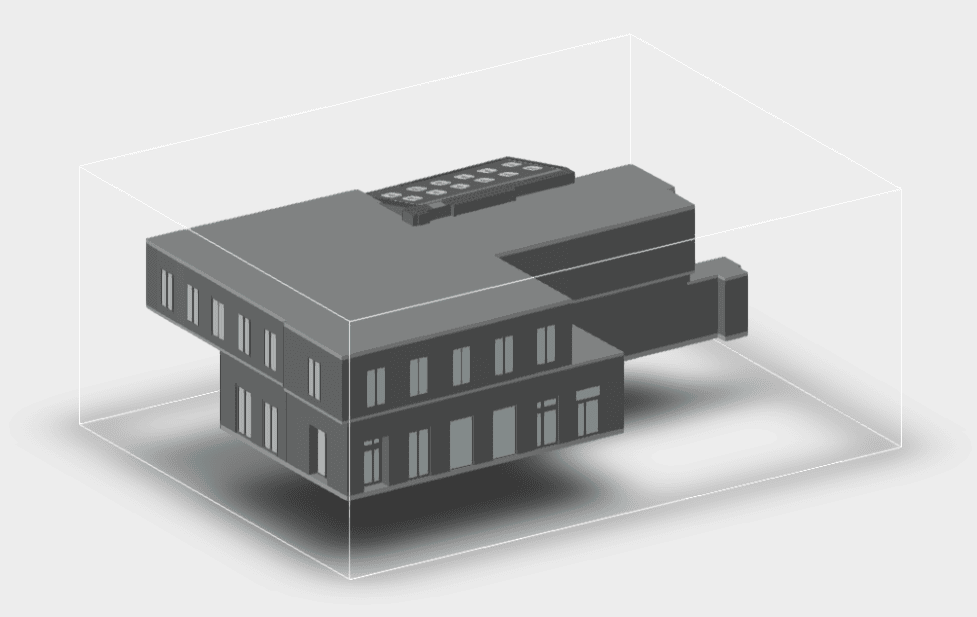

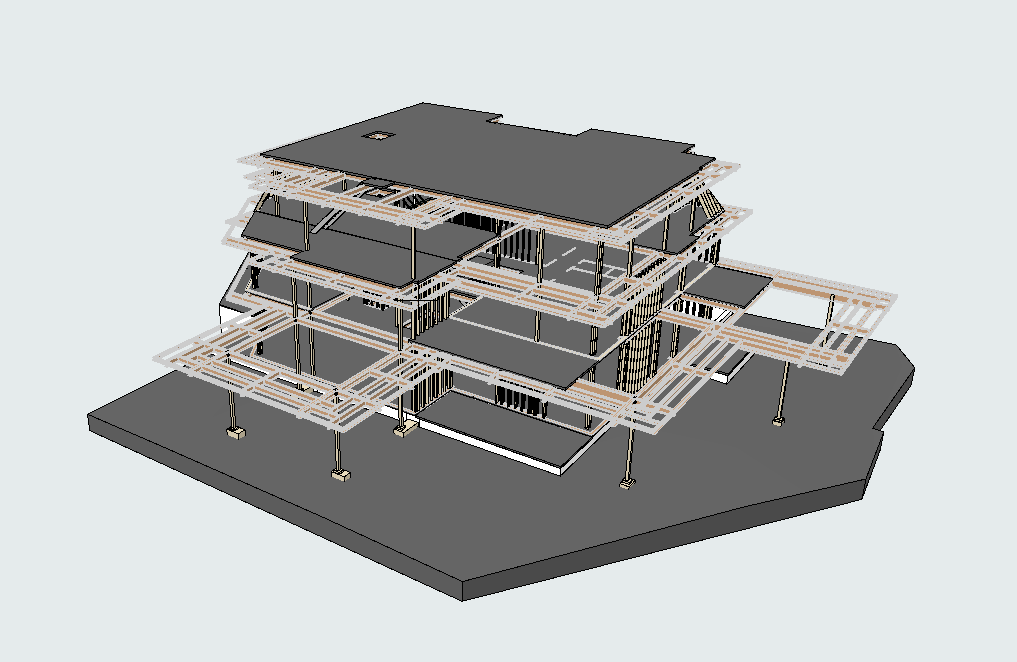

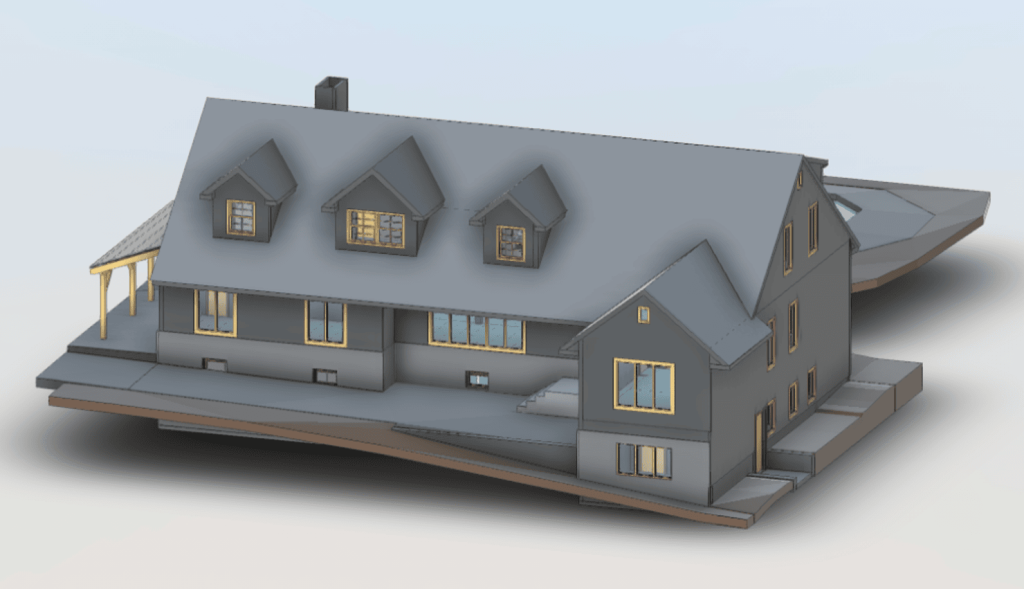

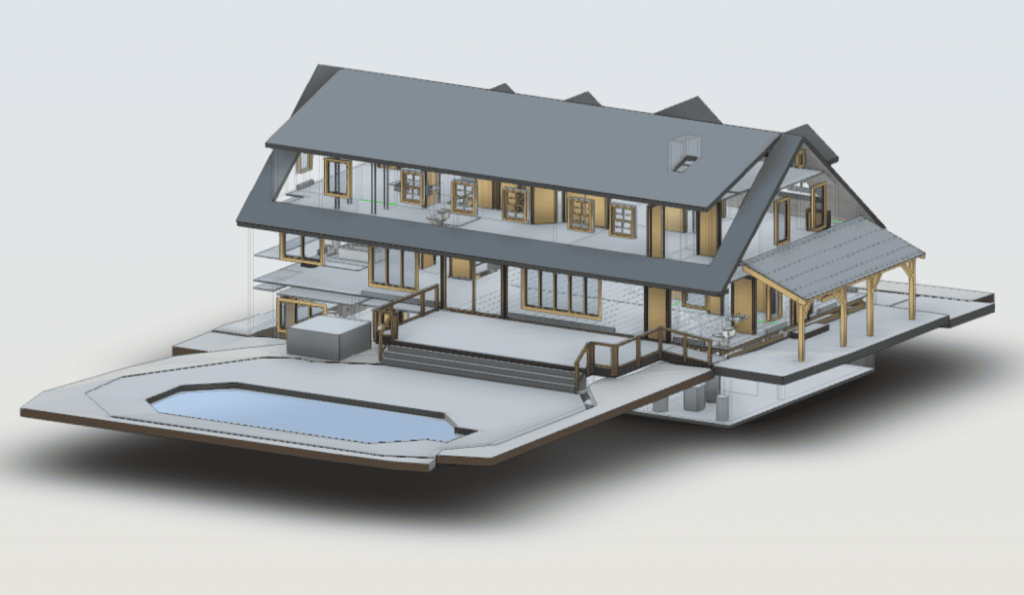

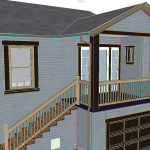

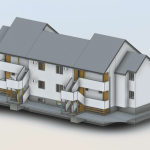

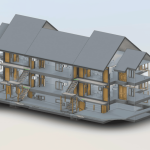

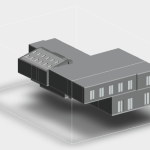

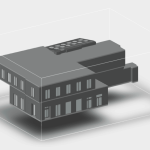

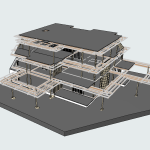

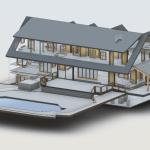

Our 3D Models Examples

The Accuracy Gap Between Traditional and Advanced Methods

In any project, accuracy is the cornerstone of success. Whether you are constructing a new building or renovating an existing one, even minor measurement errors can result in expensive mistakes and project delays.

Unmatched Precision

Traditional tools are susceptible to human error. A slight misalignment of a tape measure or an incorrect angle with a laser rangefinder can lead to inaccurate data. Laser 3D scanning, however, delivers precision down to the millimeter. Such a high degree of accuracy guarantees consistent and dependable measurements, minimizing the chances of rework.

For instance, when creating blueprints for a factory upgrade, using laser scanning ensures that every machine’s position is mapped precisely, avoiding clashes during installation and optimizing the use of available space.

Data Integration

Another advantage of laser scanning is its ability to integrate seamlessly with advanced design and modeling software such as BIM (Building Information Modeling) and CAD (Computer-Aided Design). Traditional measurements often need to be manually entered into these systems, which increases the chances of errors. Laser scanners provide point cloud data that can be directly imported, streamlining the workflow and improving overall project accuracy.

Repeatability

In projects that require multiple phases or ongoing monitoring, consistency is critical.

Laser scanners ensure that repeated measurements are identical, eliminating discrepancies that often arise with traditional tools.

Versatility Across Applications

Laser scanning isn’t just for large-scale projects. It can be applied to everything from interior design and residential construction to large-scale infrastructure projects. This versatility makes it an essential tool for professionals in a wide range of industries, such as healthcare, education, and manufacturing.

Why Choose Laser 3D Scanning for Construction Projects?

The advantages of laser 3D scanning extend beyond speed and accuracy. This technology is shaping the future of construction by enabling professionals to:

- Visualize projects in 3D for better planning and decision-making: With a highly detailed 3D model, architects and engineers can foresee challenges before they arise, improving overall project outcomes.

- Detect potential issues early: Structural inconsistencies, misalignments, or spatial conflicts can be identified in the planning stages, reducing costly errors during construction.

- Reduce waste and material costs: Accurate measurements allow for precise material estimates, minimizing surplus and ensuring resources are used efficiently.

- Enhance collaboration: Sharing 3D models with stakeholders, including contractors and clients, fosters better communication and understanding of the project’s scope.

- Monitor progress in real time: Laser scanning can be used throughout the construction process to compare current conditions with design plans, ensuring that the project stays on track.

Additionally, laser 3D scanning is invaluable for renovations and restorations. Whether it’s preserving historical landmarks or modernizing an industrial facility, the technology provides an accurate and detailed baseline for planning and execution.

Conclusion: The Future of Measurement is Here

While traditional measuring tools have served their purpose for decades, the advent of laser 3D scanning technology marks a turning point for industries that rely on precise measurements. By offering unparalleled accuracy, speed, and safety, laser scanning is setting new standards for efficiency and reliability.

In addition to its immediate advantages, laser scanning is driving the development of more innovative practices. With the integration of technologies like AI and machine learning into laser scanning systems, the range of potential applications is growing rapidly. From creating digital twins of buildings to enhancing sustainability through precise resource management, the possibilities are endless.

Professionals looking to stay competitive should consider investing in laser 3D scanning technology to future-proof their projects. The blend of affordability, precision, and efficiency establishes it as a crucial tool for contemporary construction and design.

For more information about how laser 3D scanning can transform your next project, visit scanm2.com. Our team excels in providing state-of-the-art scanning solutions customized to fit your unique requirements.