3D Models for Structural Damage Analysis in Building Inspections

The way we inspect buildings has undergone a revolution in recent years. Traditional methods, while effective in their time, often fall short of delivering the accuracy and detail needed to fully understand structural damage. This gap has been filled by advanced technologies like 3D modeling and laser scanning, which are now at the forefront of structural damage analysis. These tools not only provide unparalleled insights but also make the inspection process more efficient and reliable. In this article, we dive into how these technologies work and why they’re becoming indispensable for building professionals.

The Critical Importance of Structural Damage Analysis

Every building has a story to tell, and structural damage is often a key chapter. Whether caused by natural disasters, aging, or design flaws, damage can compromise a building’s safety and functionality.

Timely identification and precise evaluation are essential for avoiding major failures and reducing the expenses associated with repairs. But conventional inspection techniques often struggle to uncover hidden issues or provide a comprehensive picture.

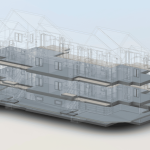

This is where 3D models shine. They capture the intricate details of a structure, making it easier to identify weaknesses, track changes over time, and develop effective repair strategies. By combining cutting-edge laser scanning with expert analysis, these models offer a window into a building’s true condition.

How 3D Models Enhance Building Inspections

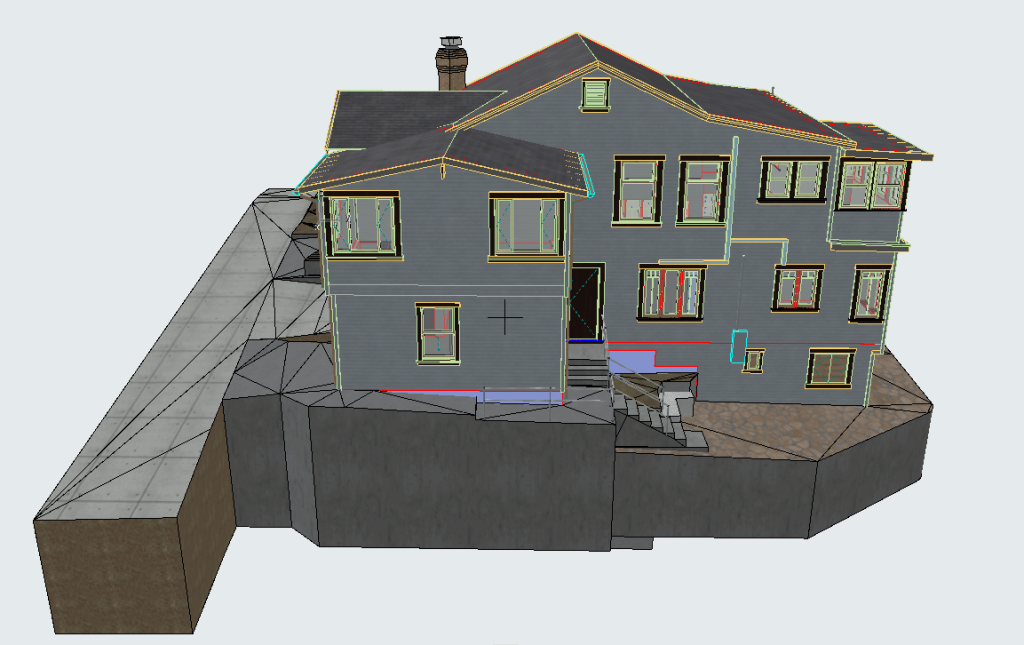

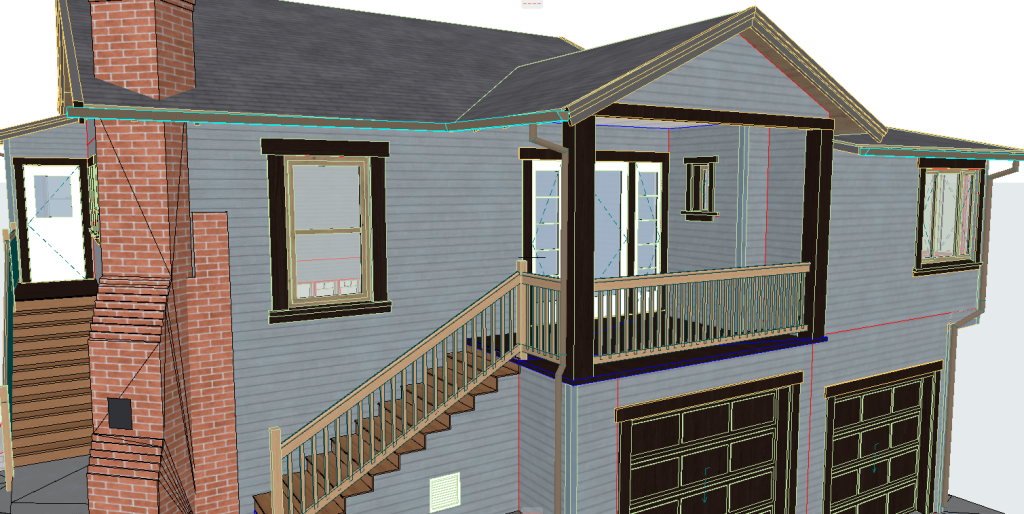

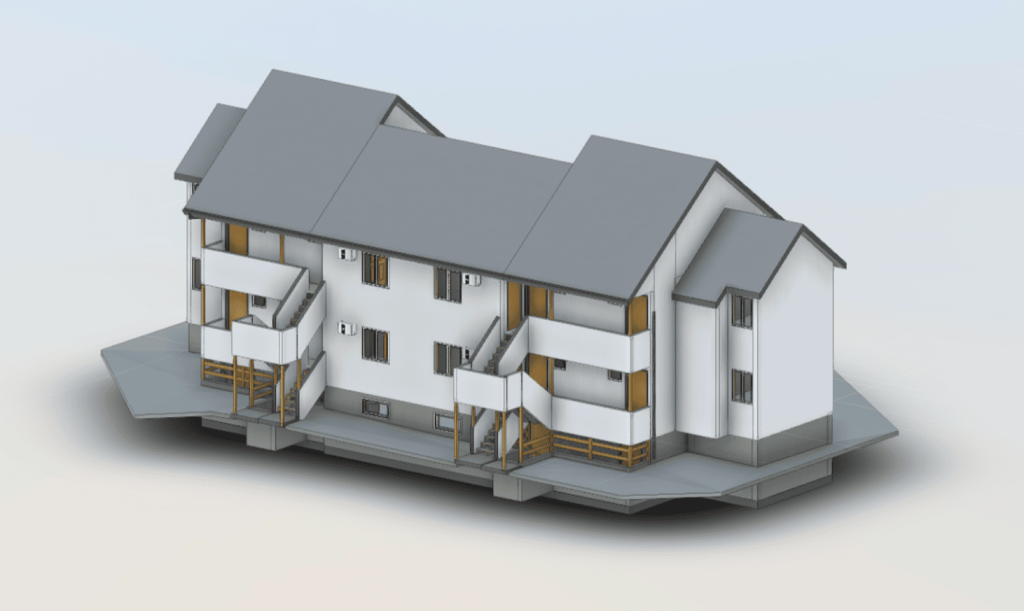

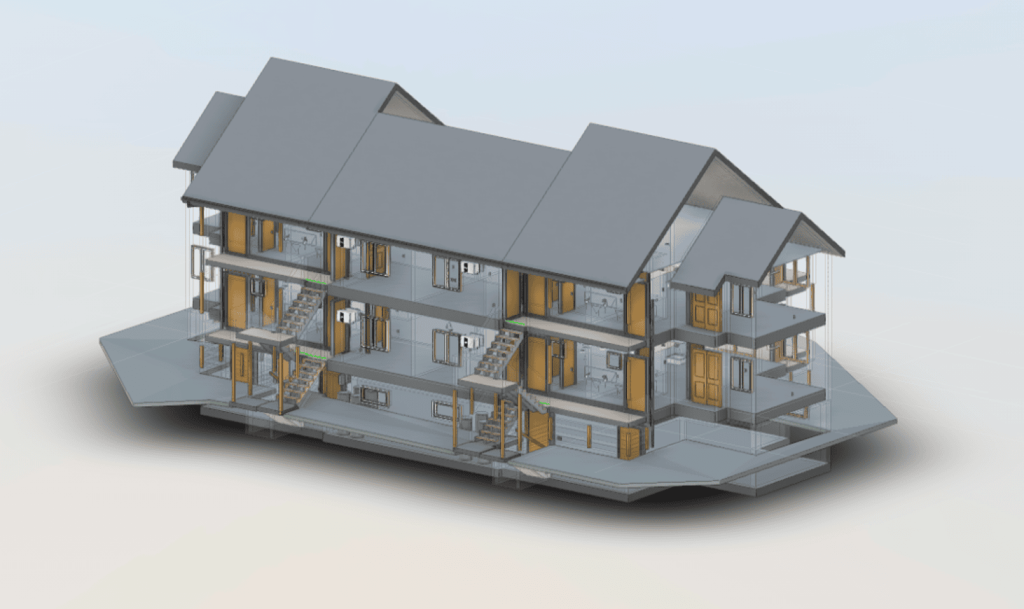

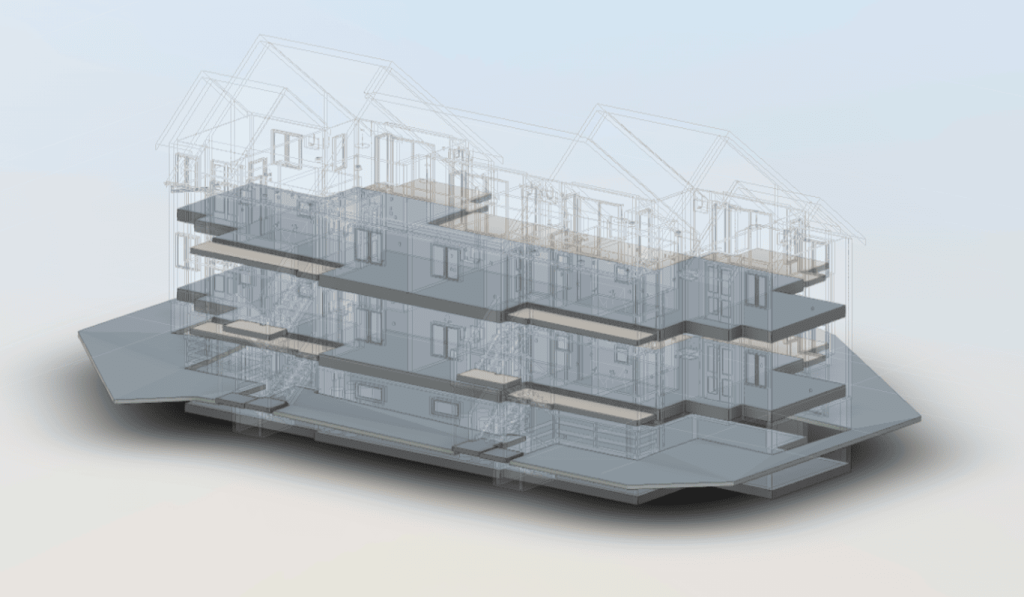

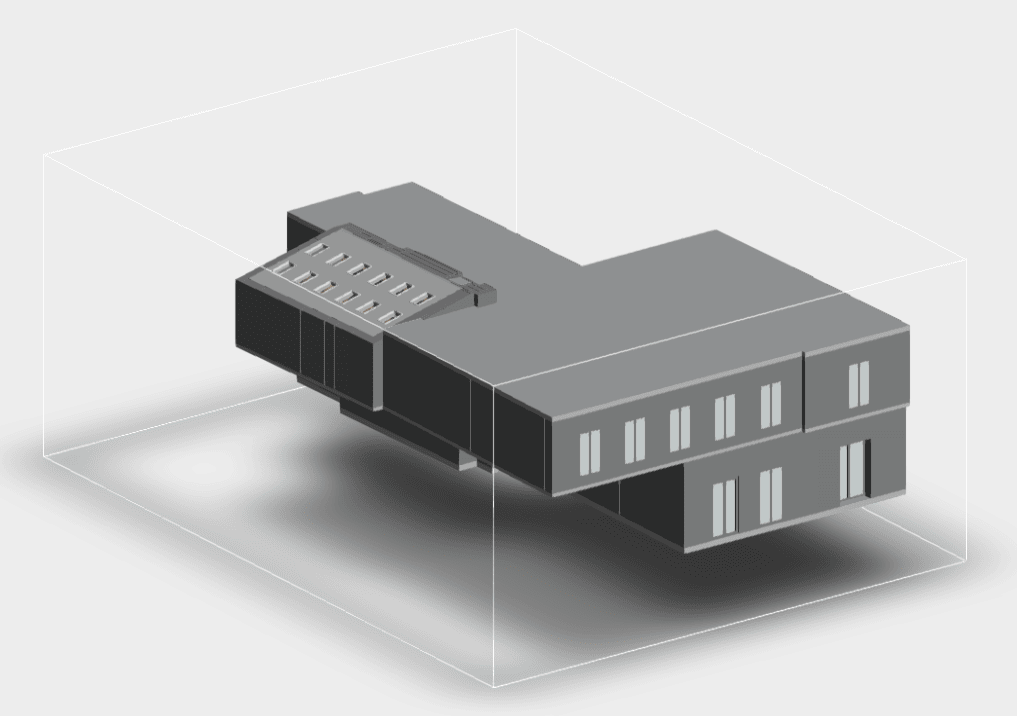

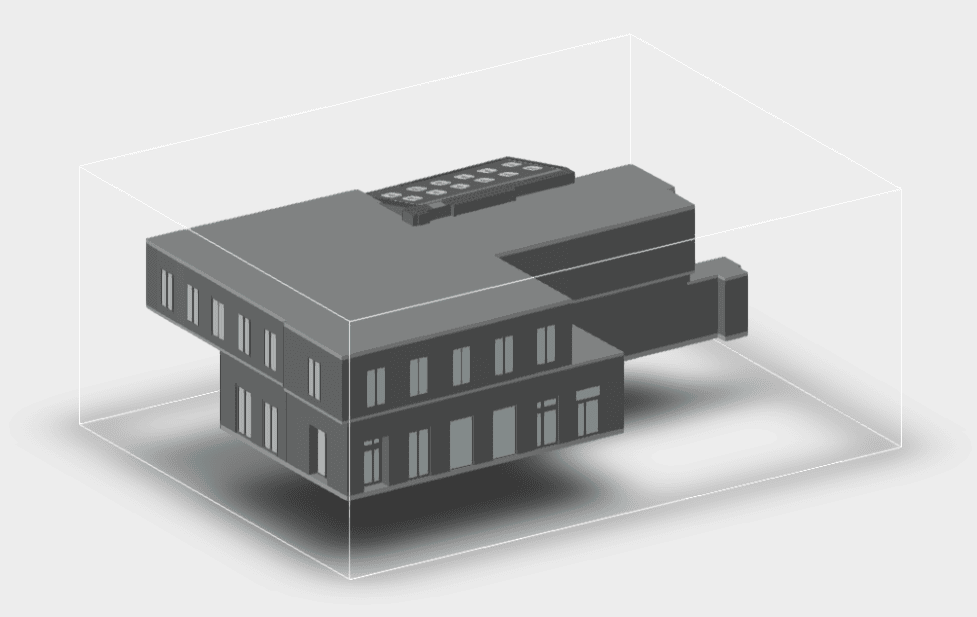

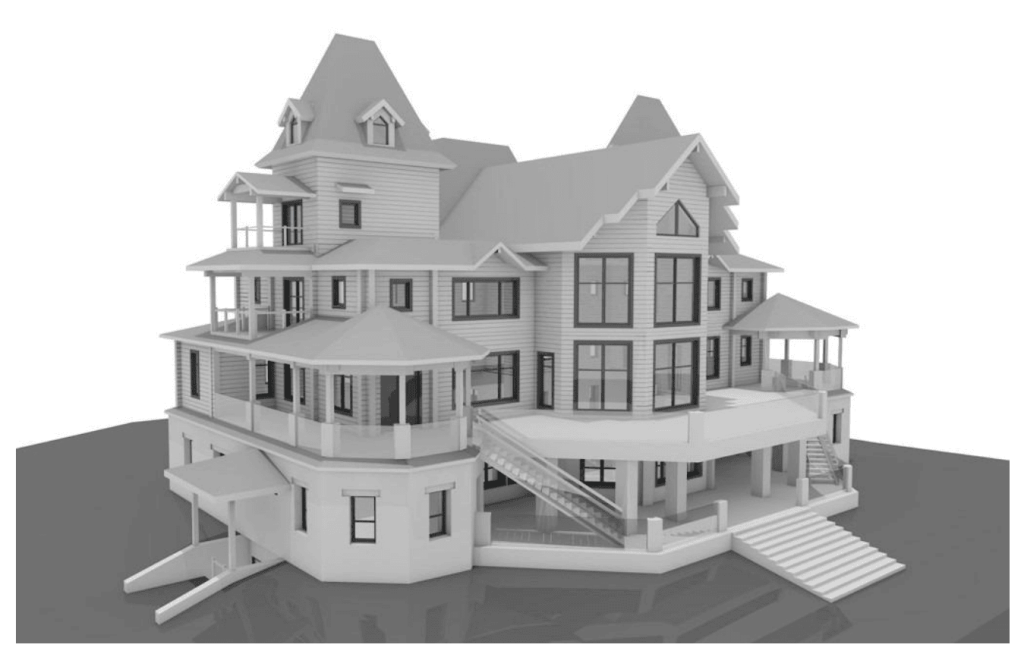

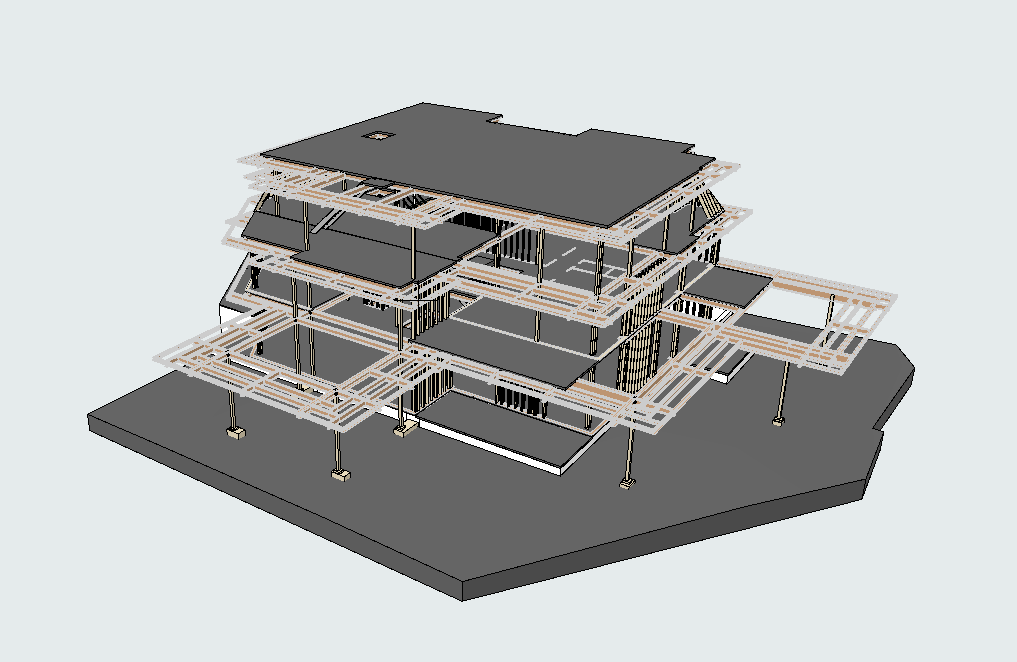

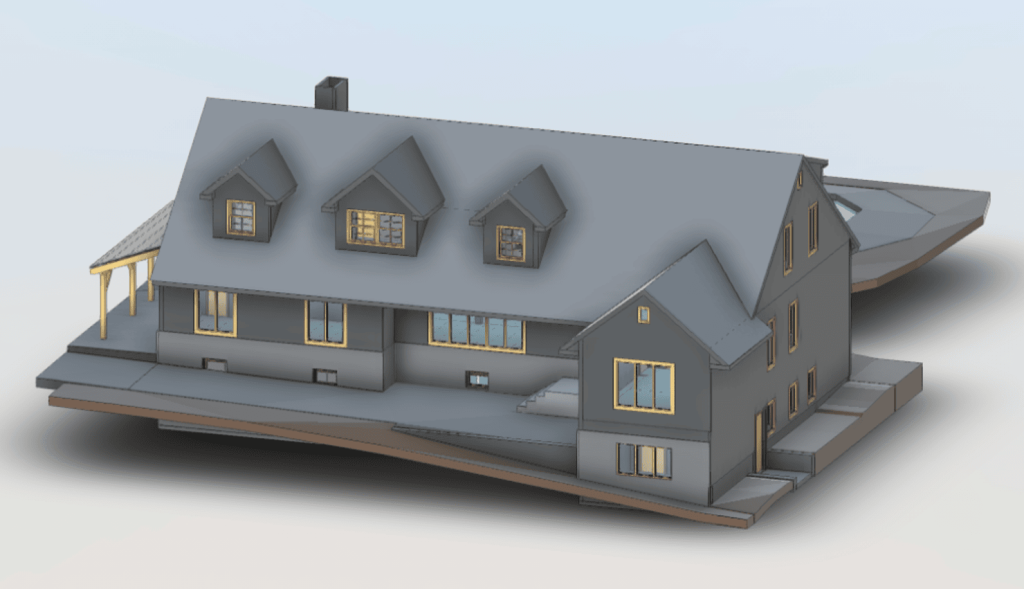

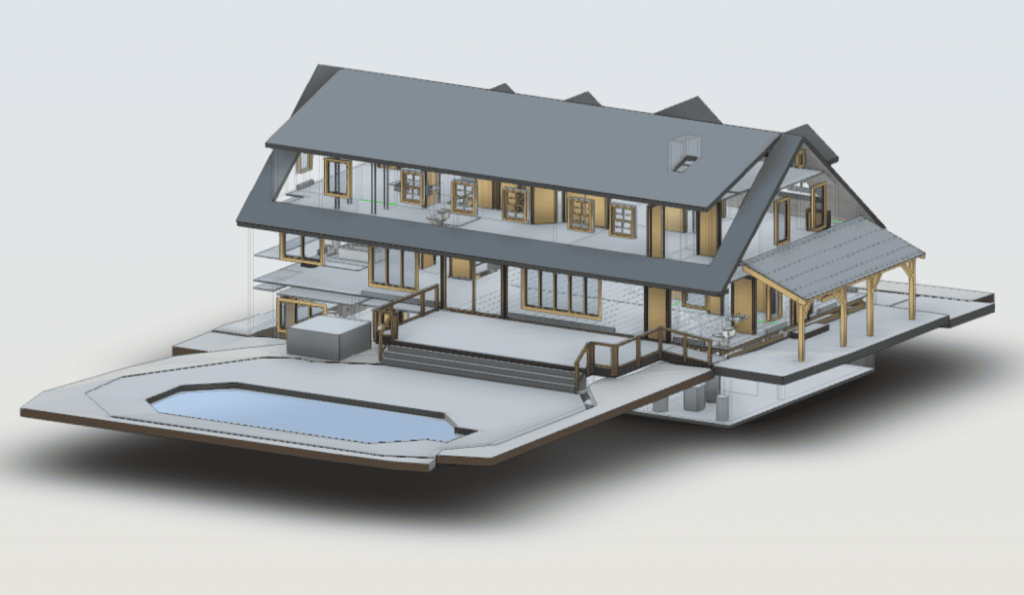

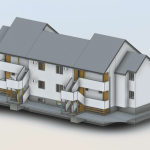

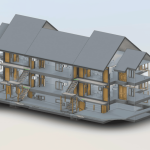

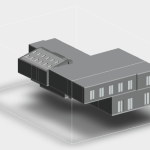

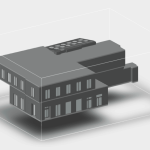

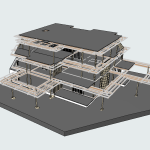

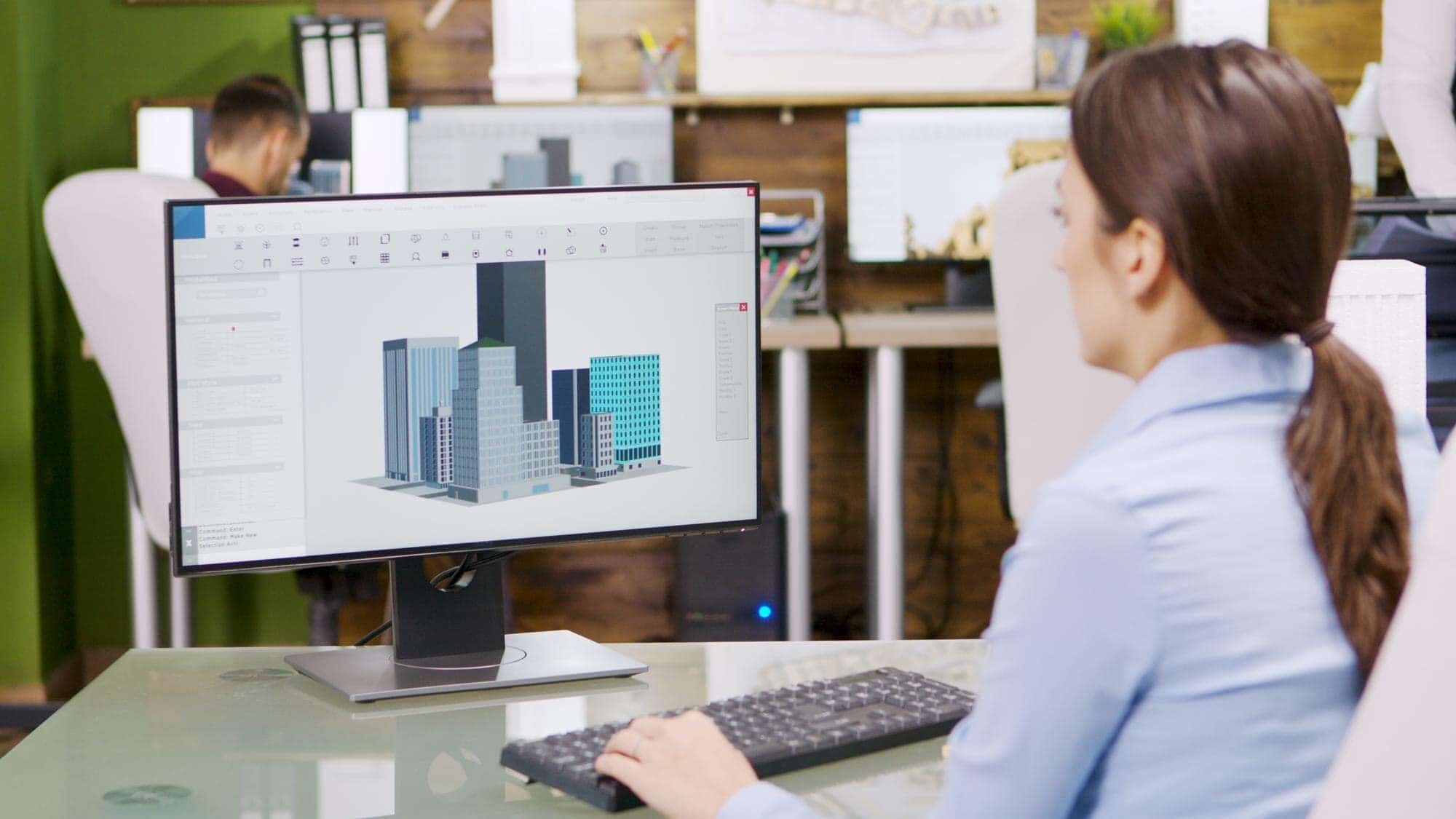

Imagine walking through a virtual replica of a building, where every beam, joint, and crack is rendered in stunning detail. That’s the power of 3D modeling. By transforming raw data into visually rich digital models, inspectors can dive deep into structural analysis without ever setting foot on-site. These models do more than just look impressive; they offer actionable insights that can make or break a project.

For instance, consider the challenge of assessing damage to a complex structure like a high-rise building or an industrial facility. Traditional inspection methods might miss small but critical issues, such as hairline cracks or slight misalignments. A 3D model, however, provides a comprehensive view that includes even the smallest anomalies. This enables inspectors to not only locate the problem but also understand its potential impact on the overall structural integrity.

Moreover, 3D models allow for simulations and stress tests to be performed digitally. Engineers can use the data to evaluate how different repair strategies might affect the building’s performance over time. Such predictive analysis plays a crucial role in guaranteeing safety and reliability over the long term.

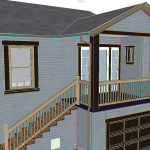

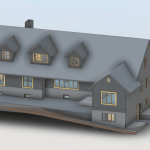

Our 3D Models Examples

Why Accurate Reports Matter

A detailed report isn’t just a formality—it’s the foundation for effective decision-making. Reports generated from 3D models offer unparalleled clarity and precision, setting a new standard in detail and accuracy. They’re not just about documenting damage; they’re about telling the story of the building in a way that’s actionable and meaningful.

For instance, when assessing structural damage after a natural disaster, the details matter. An accurate report can specify the extent of damage, the materials affected, and the urgency of required repairs. This enables property owners, engineers, and contractors to prioritize tasks and efficiently distribute resources.

In addition to clarity, these reports also offer quantifiable data. Measurements taken from 3D scans are precise, allowing for exact cost estimations and repair schedules. This is particularly useful in insurance claims or legal disputes, where evidence needs to be indisputable. A high-resolution 3D rendering included in the report can visually demonstrate the condition of the structure, making it easier to convey complex information to stakeholders.

Another advantage is the speed at which these reports can be generated. With automated data analysis tools, the time between inspection and actionable insights is significantly reduced. This means less downtime for property owners and faster responses to urgent structural issues.

Applications That Are Changing the Game

After Natural Disasters

Following disasters such as hurricanes or earthquakes, rapid response becomes critical. Rapid assessments are crucial for prioritizing repairs and ensuring public safety. 3D models created from laser scans can quickly reveal the extent of the damage, enabling informed decisions.

Aging Structures

Just as people experience wear and tear over time, buildings also exhibit signs of aging. 3D scanning provides a clear picture of how a structure is holding up over time. By comparing scans taken at different intervals, engineers can identify patterns of deterioration and predict future issues.

Renovation and Retrofitting

Before you can fix or upgrade a building, you need to know exactly what you’re working with. 3D models offer a precise map of the existing structure, ensuring renovations are planned and executed with confidence. This helps minimize the likelihood of unexpected and expensive issues in the future.

Legal and Insurance Documentation

When disputes arise over structural damage, having a 3D model can be a game-changer. It provides irrefutable evidence of a building’s condition, which can be critical for settling insurance claims or legal cases.

The Future of Building Inspections

The integration of 3D modeling and laser scanning into building inspections is just the beginning. New advancements, such as artificial intelligence (AI) and machine learning, are poised to revolutionize the field of structural damage analysis.

These advancements could enable predictive analytics, automated damage detection, and real-time monitoring, making inspections even more precise and proactive.

For example, imagine a system that not only identifies a crack in a beam but also predicts when it might fail based on historical data and environmental conditions. This level of foresight could revolutionize maintenance planning and significantly reduce risks.

Conclusion

The field of building inspections is undergoing significant change, with 3D models leading the way in this transformative process. By providing detailed, accurate, and actionable insights, they empower professionals to tackle structural challenges with confidence. 3D modeling and laser scanning significantly improve inspection accuracy while simplifying the process, resulting in time and resource savings.

With ongoing technological advancements, the potential for structural damage analysis continues to grow. Incorporating AI and predictive analytics is expected to enhance the reliability and efficiency of inspections even further. Whether you’re a property owner, engineer, or contractor, leveraging these tools will be critical for navigating the complexities of modern construction and maintenance.

3D models aren’t just tools; they’re partners in ensuring safety, sustainability, and success. Embracing these technologies not only ensures your projects are future-ready but also helps create a safer and more intelligent built environment.