Everything You Need to Know About 3D Laser Scanning

In the rapidly evolving world of construction, architecture, and engineering, 3D laser scanning has emerged as a groundbreaking technology that is transforming how professionals approach design, planning, and execution. With this advanced tool, scanning complex environments becomes faster, more accurate, and highly detailed—allowing for seamless project management from start to finish.

What is 3D Laser Scanning?

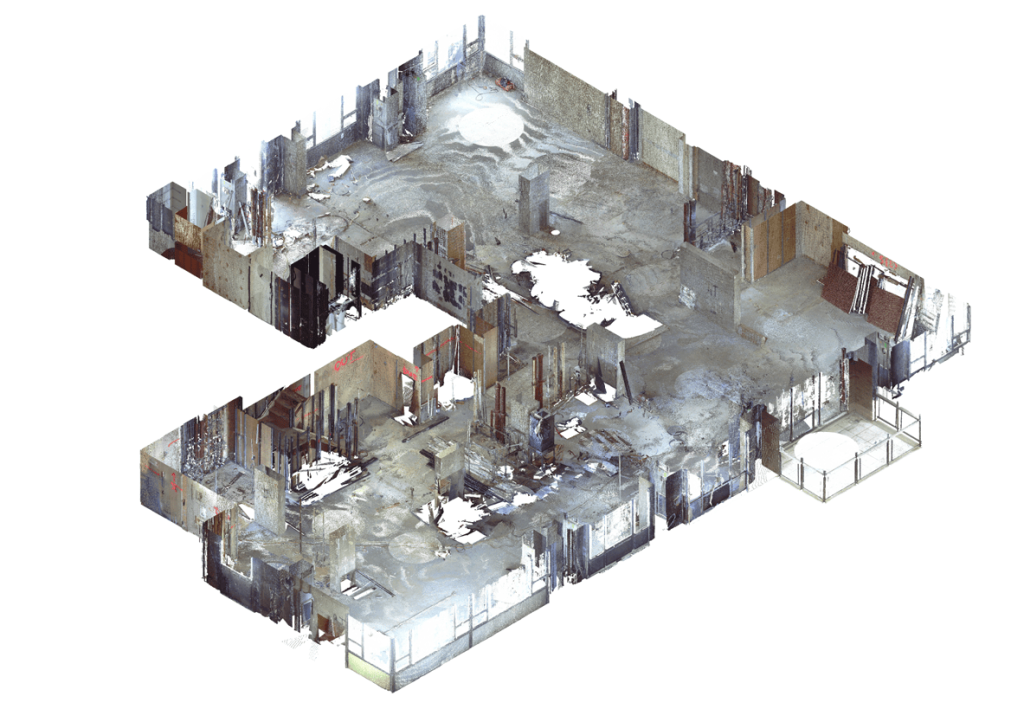

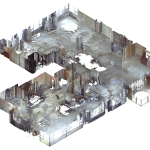

Fundamentally, 3D laser scanning is a technique that uses laser light to precisely capture the exact dimensions and form of an object or environment. The process involves emitting laser beams at a target, and then recording the light that bounces back. By timing how long it takes for the laser to return, the scanner generates a “point cloud”—a collection of millions of data points that represent the scanned surface. These points are then used to develop highly accurate 3D models.

This technique is widely used in industries such as construction, architecture, reverse engineering, and industrial design, as it provides precise measurements and details that are difficult, if not impossible, to obtain through traditional methods.

The Problems 3D Laser Scanning Solves

The need for accuracy in design, planning, and execution is critical in industries like construction and engineering. Here are some of the common challenges that 3D scanning services can solve:

- Precision in Design: When creating complex structures, traditional measuring tools often fall short. 3D building scanners ensure millimeter-level accuracy, reducing the margin for error in the design process.

- Time-Consuming Manual Work: Collecting data manually for large sites or intricate designs can take weeks. 3D laser scanning dramatically reduces the time needed for surveying, while maintaining an exceptional level of detail.

- Inconsistent Data: Manual surveys can lead to discrepancies and missed details, which can be costly to fix later in the project. 3D scanning ensures all data is collected in one go, providing a unified source of truth for all stakeholders.

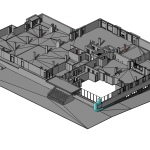

- Inefficient As-Built Documentation: As-built surveys require precise documentation of existing structures, and traditional methods may miss crucial details. Lidar scanning offers detailed records that can be revisited digitally, saving time and preventing rework.

Our 3D Scanning Services: Process & Results

How 3D Laser Scanning Works

The process of 3D laser scanning is remarkably straightforward yet highly sophisticated. It involves three main steps:

Data Capture

When operating a 3D laser scanner (like those from Leica or Faro), the device emits laser beams toward the object or environment being scanned. The beams reflect back to the scanner, which records the time it took for the laser to return. From this data, the device calculates the exact distance between the scanner and various points on the object or surface.

Data Processing

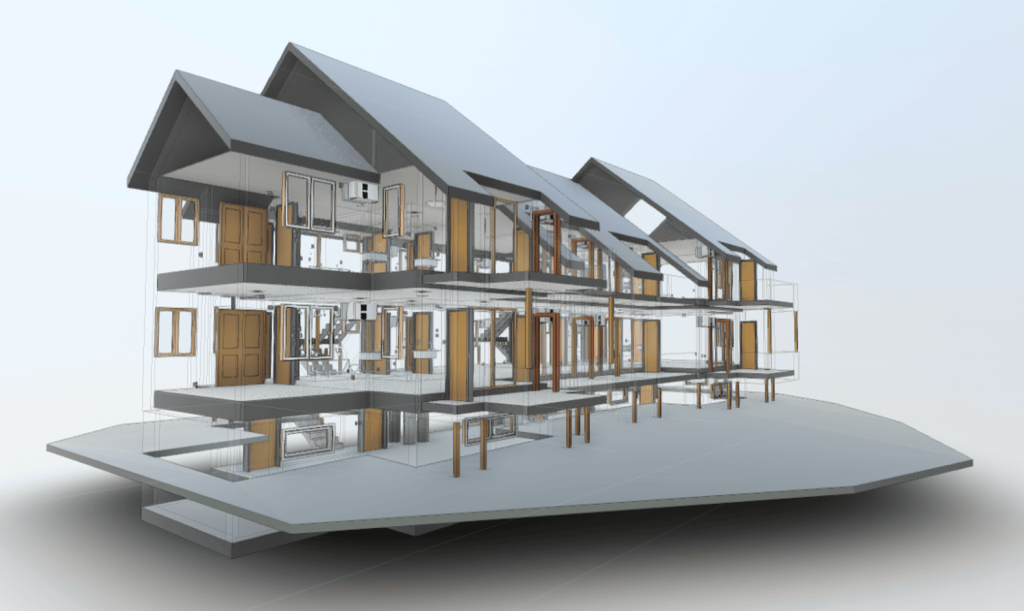

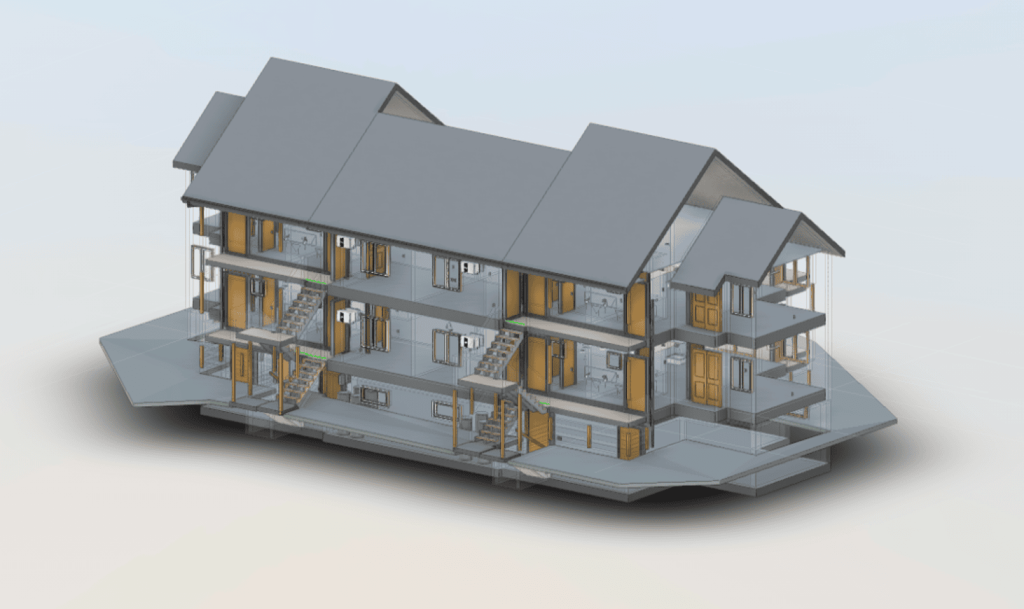

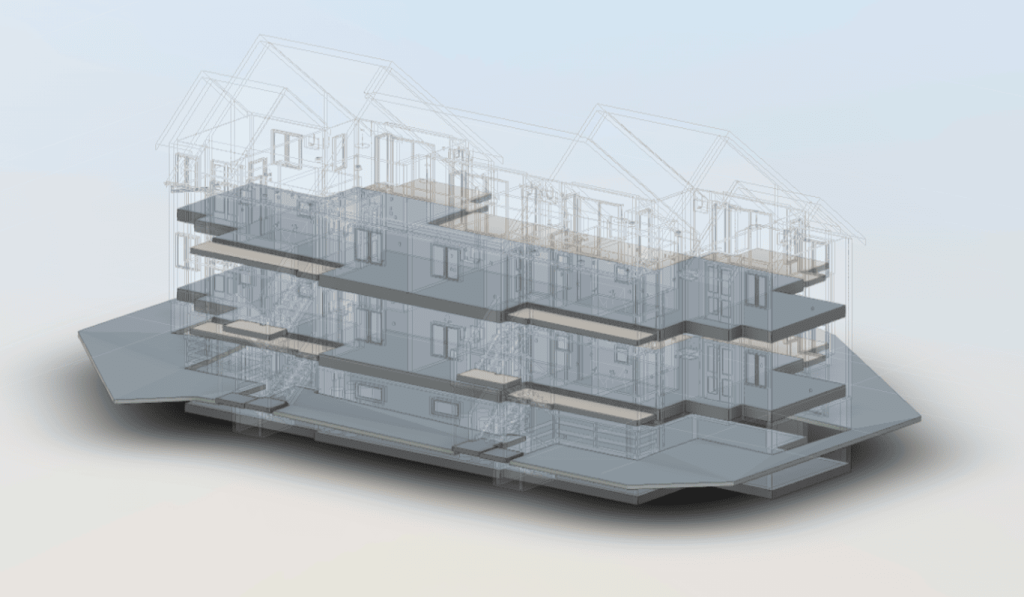

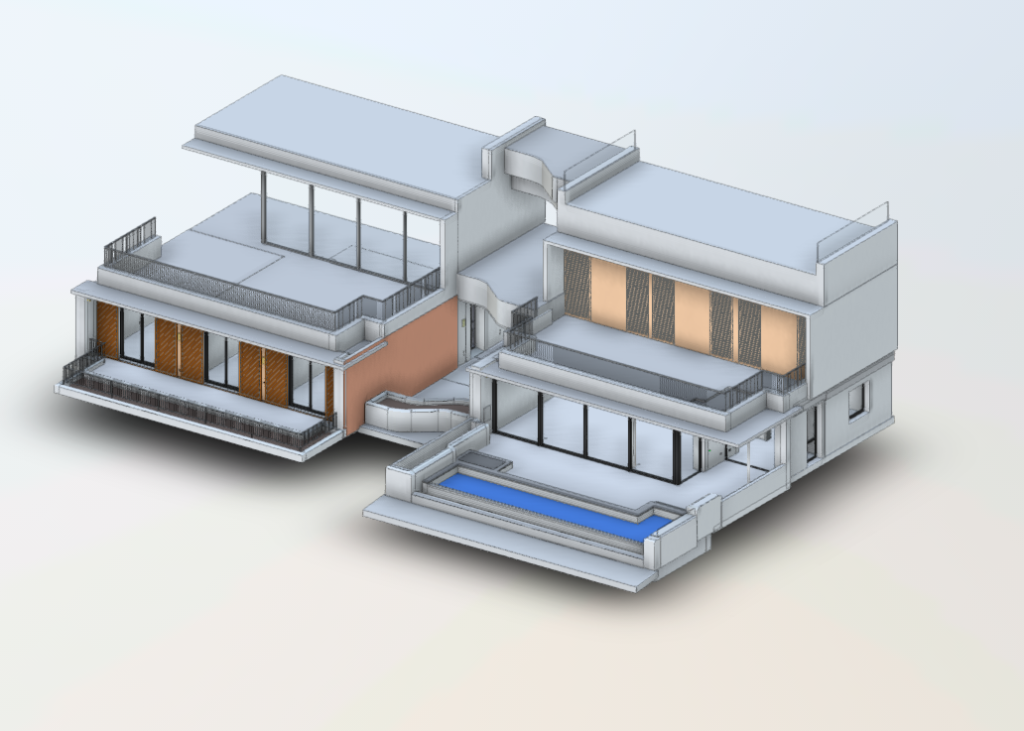

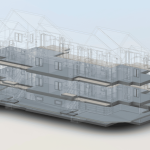

Once the scan is complete, the raw data—millions of points in a “point cloud”—is processed using specialized software. This software compiles the data into a cohesive 3D model that accurately reflects the scanned environment. This stage is where data is cleaned up and refined, removing any noise or irrelevant information that may have been captured during scanning.

Deliverables and Output

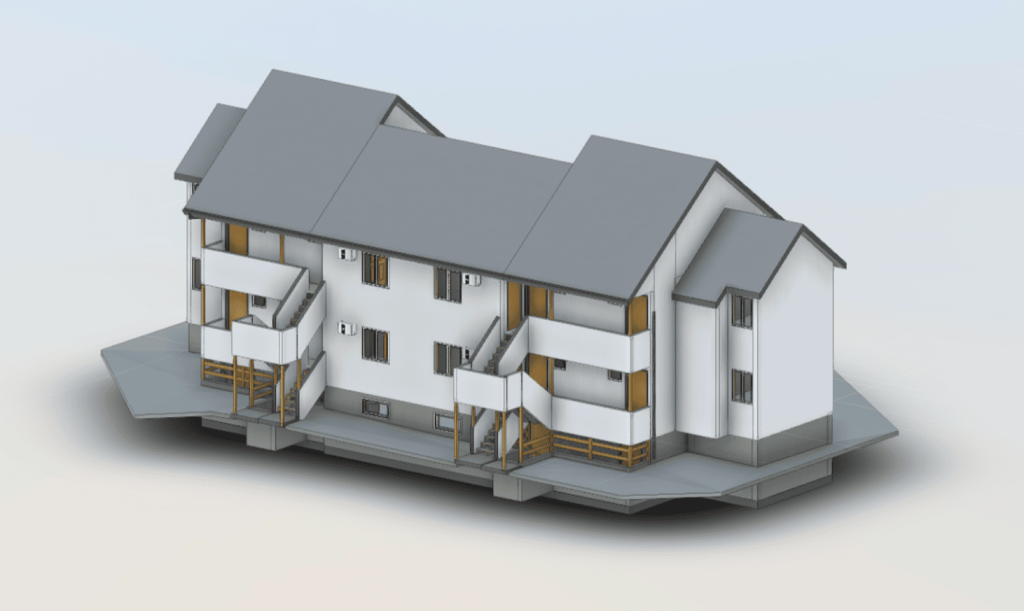

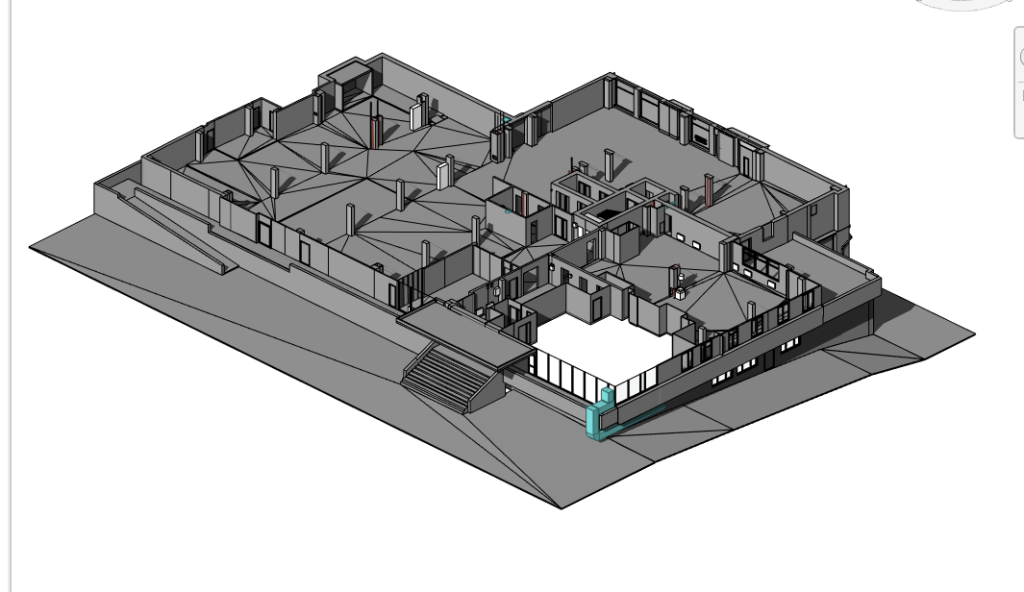

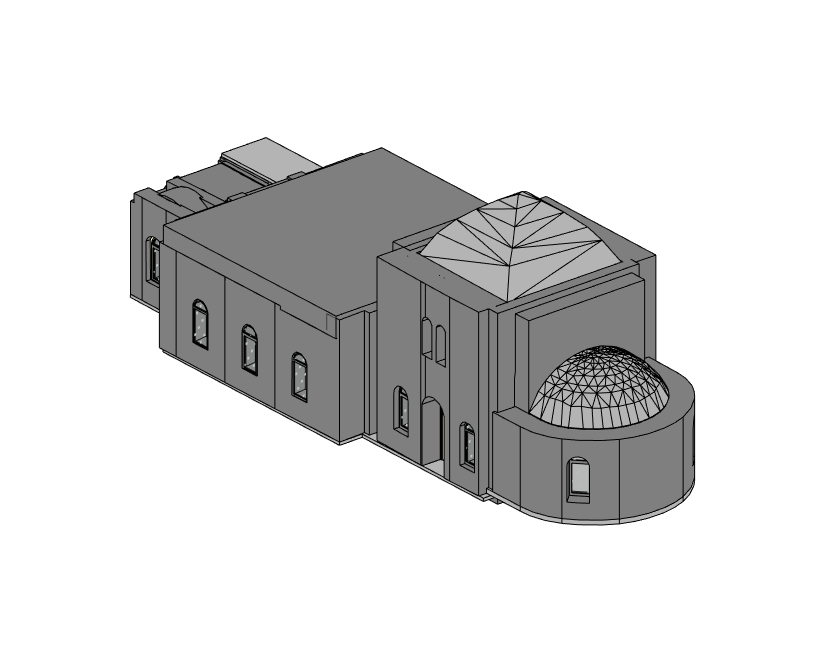

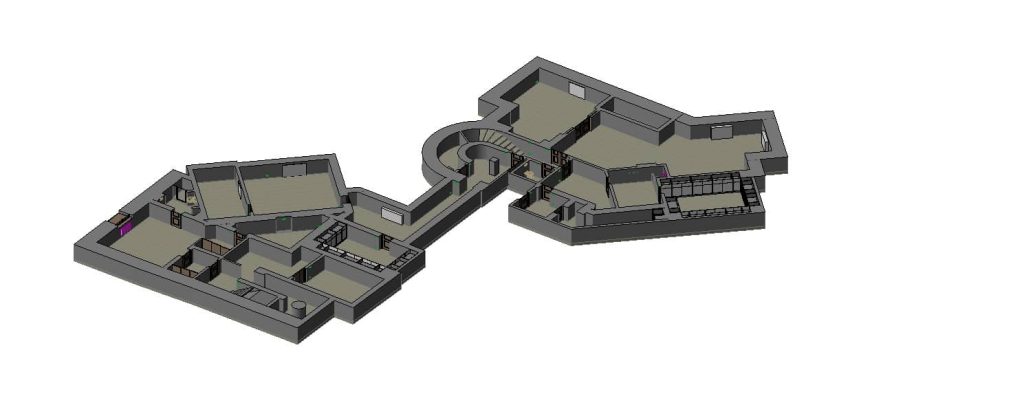

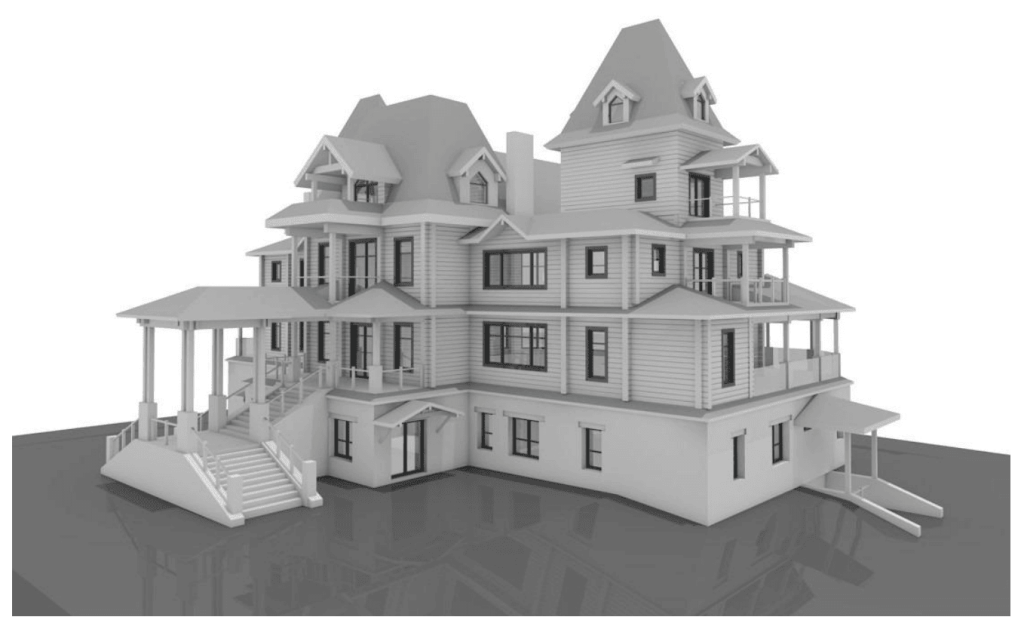

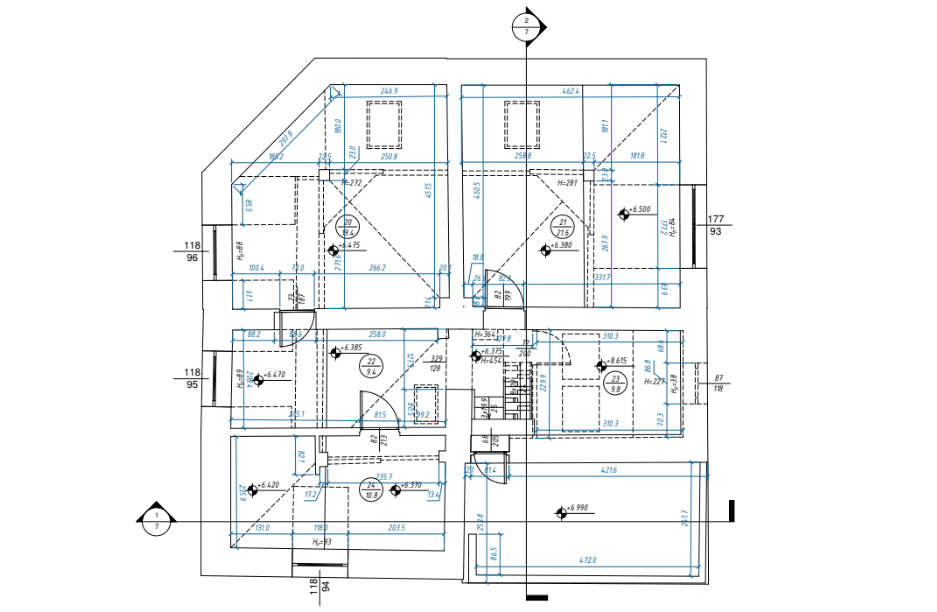

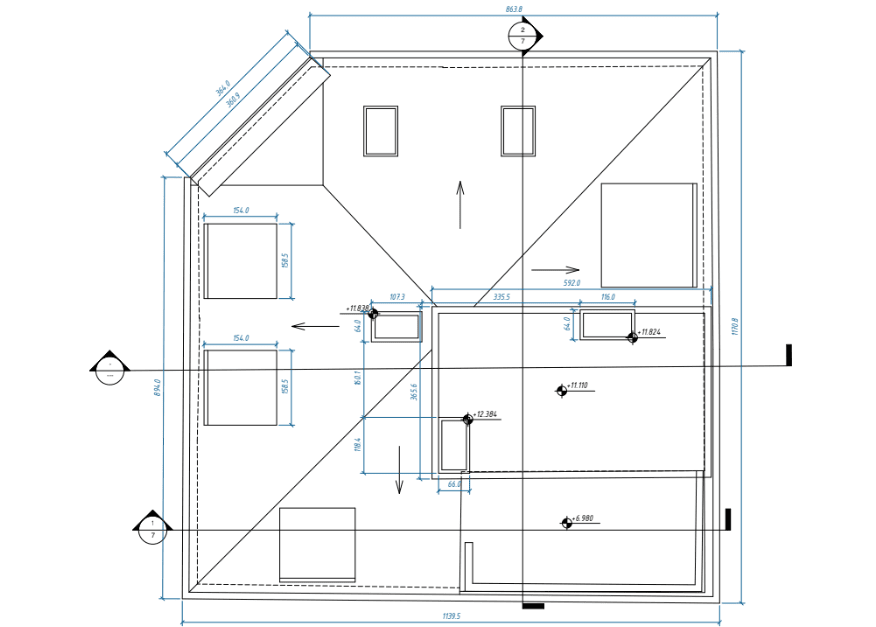

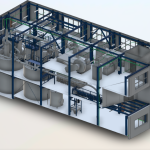

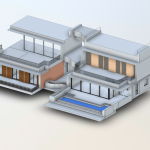

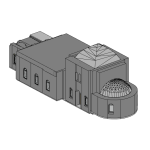

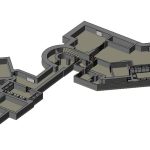

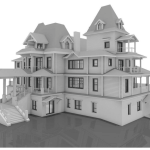

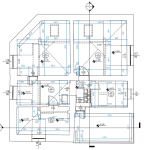

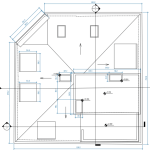

The final 3D model is then shared with the client in a variety of formats depending on the project’s needs. This could be a Scan to BIM file, CAD file, or another 3D model format. For professionals like architects, engineers, and designers, these detailed models are invaluable for making informed decisions and reducing project risks.

Why 3D Laser Scanning is Better than Traditional Methods

Traditional surveying techniques, while effective in their time, have several limitations, especially when compared to modern 3D laser scanning technology. Here’s why:

Speed and Efficiency

Traditional methods such as manual tape measures, theodolites, and even photogrammetry can take days or weeks to gather data, especially on large or complex projects. 3D scanning services reduce this time to just a few hours, providing immediate access to precise, detailed data.

Accuracy and Detail

Manual surveys are prone to human error. While traditional methods might be accurate to within centimeters, 3D scanners can capture data with millimeter precision, ensuring no detail is overlooked.

Flexibility

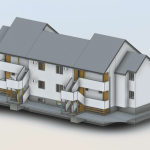

One of the key benefits of 3D scanning is its remarkable versatility. It can be used to scan everything from small objects to large structures like buildings, roads, and bridges. Whether you’re working on an as-built survey or creating a 3D model for reverse engineering, laser scanning can accommodate a wide range of project scopes.

The Full 3D Scanning Process

For clients interested in 3D scanning services, understanding the process from start to finish is essential. Here’s a breakdown of what to expect:

Step 1: Initial Consultation and Project Scoping

To begin, we start with a consultation to discuss the unique requirements of your project. This is where you’ll provide details about the space, object, or environment that needs to be scanned, along with any specific deliverables you may need (such as Scan to BIM services or reverse engineering files).

Step 2: On-Site Scanning

Once the scope is defined, the scanning team will visit your site with advanced laser scanning equipment (such as the Leica or Faro models). The scanning duration varies based on the size of the space or object, taking anywhere from several hours to a full day. The scanner rotates, sending out millions of laser points to capture every angle of the structure.

Step 3: Data Processing

Back in the lab, the scanning team processes the collected data, compiling the point cloud into a digital 3D model. At this stage, any unnecessary data is cleaned up, ensuring a clean, accurate representation of the scanned space.

Step 4: Deliverables

Once the model is complete, it can be delivered in multiple formats depending on your project needs. For architects and construction teams, Scan to BIM services are often provided, offering seamless integration with existing project workflows. For product designers, reverse engineering data may be supplied, allowing for the creation of new designs based on the original scanned object.

Step 5: Ongoing Support

After the scanning process is complete, you may require ongoing support, whether it’s additional scans, data interpretation, or model revisions. Many 3D scanning services offer follow-up services to ensure that clients can fully leverage the data they’ve received.

What Clients Receive After a 3D Scan

Upon completion of a 3D laser scan, clients typically receive several critical deliverables, which may include:

- Point Cloud Data: This is the raw data captured during scanning, offering a highly detailed digital representation of the scanned environment.

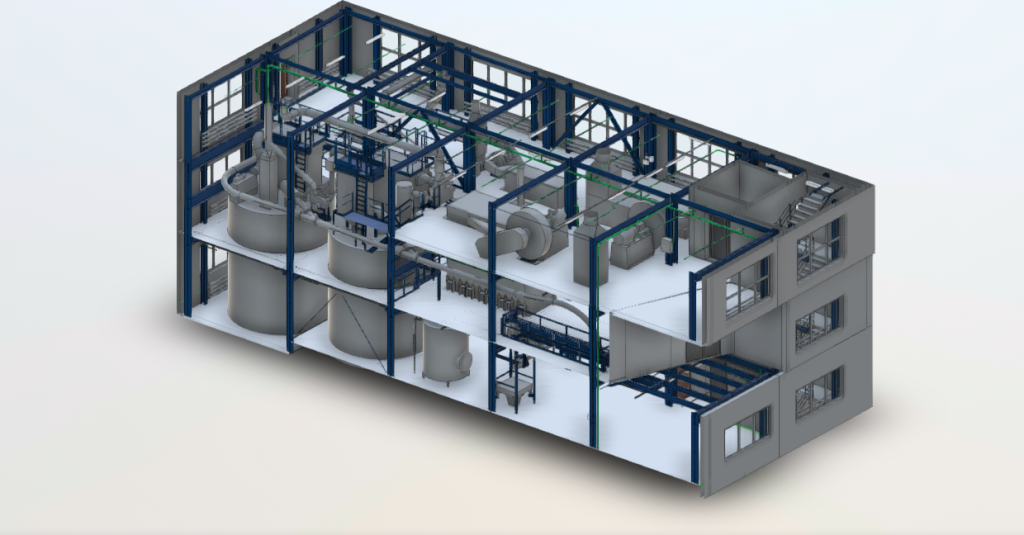

- 3D Models: Depending on the project, this could be a CAD model, a Scan to BIM file, or other formats suitable for the design or engineering process.

- As-Built Survey Documentation: For clients requiring an accurate reflection of existing conditions, as-built documentation is provided, offering a digital archive of the building or structure as it exists today.

- Analysis Reports: Some projects require more in-depth analysis, such as structural integrity assessments or environmental reports based on the scan data.

The Industries that Benefit from 3D Laser Scanning

While 3D laser scanning can be applied in a wide range of sectors, certain industries have seen transformative results from this technology:

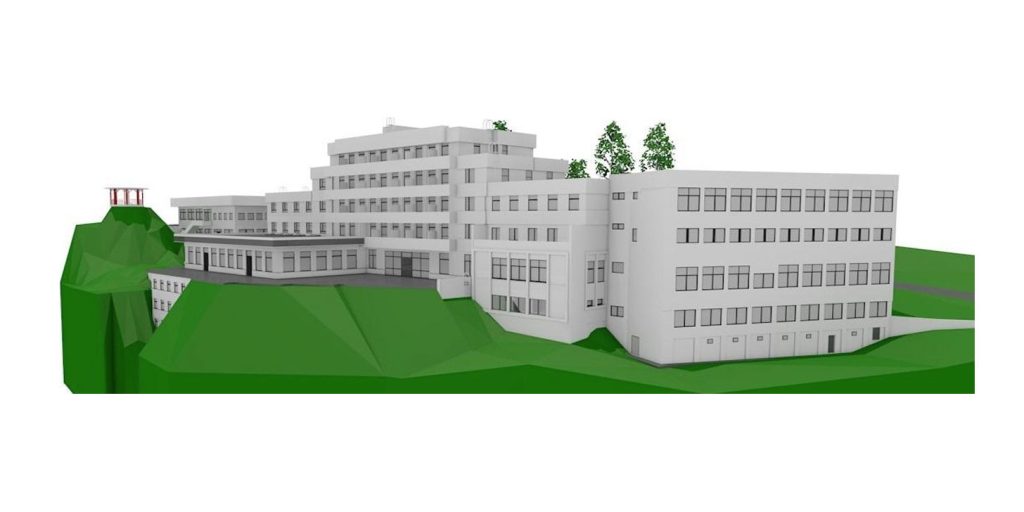

- Architecture and Design: By offering precise measurements and real-time updates to existing structures, 3D scanning helps architects design buildings that fit perfectly within their surroundings.

- Construction and Engineering: From planning to execution, scanning allows construction teams to anticipate issues, minimize risks, and avoid costly mistakes.

- Historic Preservation: For preserving historical buildings and monuments, laser scanning offers an unmatched level of detail, allowing for restoration efforts without physical contact.

- Manufacturing and Reverse Engineering: Product designers can use 3D scans to create new designs based on the exact specifications of existing objects, speeding up the manufacturing process.

Why 3D Laser Scanning is Essential for Your Next Project

3D scanning services deliver unmatched precision, speed, and adaptability when compared to traditional methods. Whether you’re an architect designing a new building, a contractor managing a complex construction project, or an engineer working on reverse engineering, laser scanning provides the detailed data you need to make informed decisions and reduce project risks.

In today’s fast-paced and competitive environment, staying ahead of the curve is crucial. 3D laser scanning not only simplifies the project lifecycle but also ensures higher accuracy and faster completion times. If you’re considering 3D scanning for your next project, it’s time to explore how this technology can streamline your workflow, minimize errors, and save time and money.

Frequently Asked Questions

What is 3D laser scanning used for?

3D laser scanning is used to capture accurate, high-resolution data of objects, spaces, and environments for design, construction, and analysis purposes.

How accurate is 3D laser scanning?

3D laser scanning provides millimeter-level accuracy, offering much higher precision compared to traditional surveying methods.

How long does a 3D laser scan take?

The required time varies according to the project’s size and complexity, typically ranging from a few hours up to an entire day.

What industries benefit from 3D laser scanning?

Industries such as architecture, construction, engineering, historic preservation, and manufacturing all benefit from the detailed data provided by laser scanning.

Can 3D scanning be used for reverse engineering?

Yes, 3D scanning is a critical tool for reverse engineering, allowing designers to create new models based on existing objects.

What deliverables will I receive after a 3D laser scan?

You will typically receive point cloud data, 3D models, as-built documentation, and potentially analysis reports, depending on your project’s needs.

Ready to take your project to the next level with 3D laser scanning?

Contact us today to discuss your unique needs and see how our state-of-the-art scanning services can bring your project to life!