How BIM is Transforming the Oil and Gas Industry

The oil and gas industry is known for its complexity, with vast infrastructure, strict safety protocols, and high operational costs. This is where Building Information Modeling (BIM) becomes crucial. As oil and gas facilities expand and evolve, BIM provides a digital solution to streamline everything from initial design to ongoing maintenance. In a world where precision, efficiency, and safety are non-negotiable, BIM in the oil and gas industry is revolutionizing how projects are managed, reducing both costs and risks.

BIM in Oil and Gas Industry: A Game-Changer for Efficiency and Safety

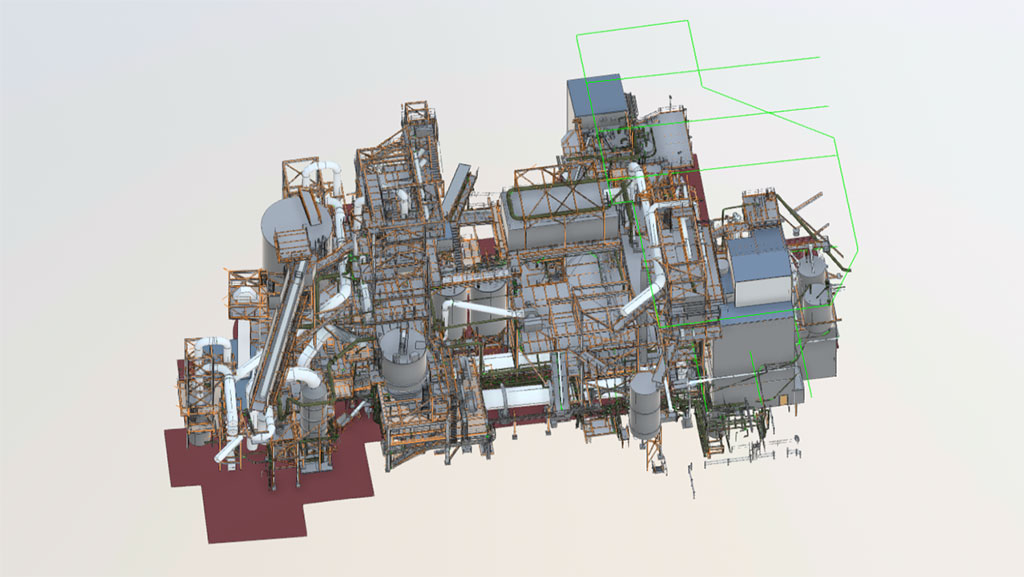

In industries like oil and gas, where infrastructure is not only massive but also extremely technical, managing the lifecycle of assets can be overwhelming. BIM, a 3D model-based technology, enables better collaboration and decision-making across all stages of a project. Through BIM oil and gas systems, complex projects are planned, designed, constructed, and managed with a level of detail and accuracy that was previously unattainable.

Unlike traditional 2D plans, BIM in oil and gas creates a comprehensive virtual model that integrates not only the physical design but also crucial data such as material specifications, costs, schedules, and more. By providing real-time insights, BIM allows engineers, architects, and managers to work cohesively, ensuring that all systems—mechanical, electrical, and structural—function harmoniously. This seamless integration is particularly vital in oil and gas, where errors can lead to costly delays or safety hazards.

The Role of BIM in Oil and Gas Facility Lifecycle Management

Managing oil and gas facilities, which can include everything from offshore platforms to refineries and pipeline networks, requires immense precision. BIM models offer real-time data that help streamline every phase of a project’s lifecycle:

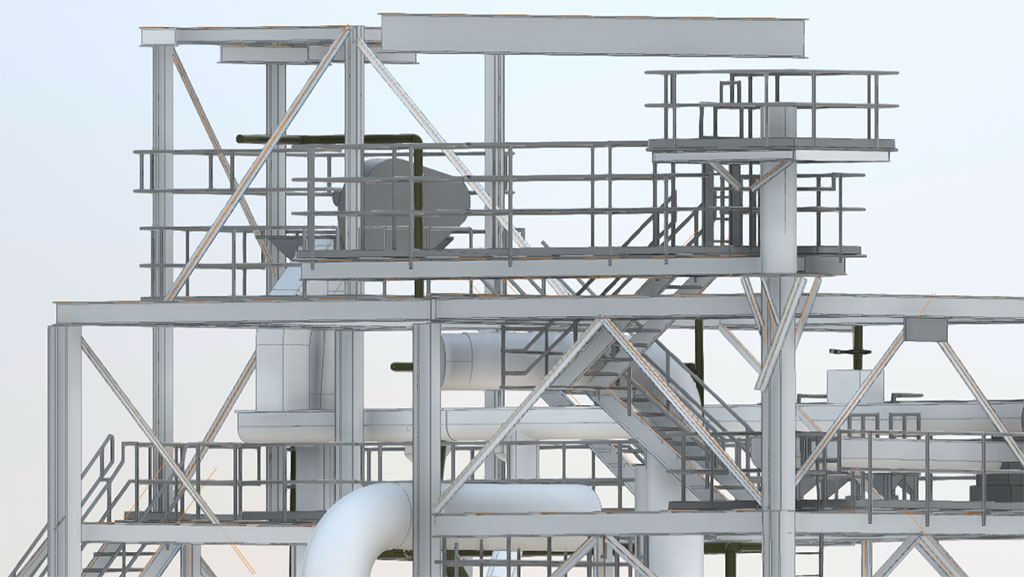

- Planning and Design: BIM aids in creating highly detailed plans for oil and gas infrastructure. Engineers can visualize every pipe, valve, and structural component, ensuring that all elements are designed to meet safety regulations and operational needs. The integration of 3D laser scanning helps capture accurate existing conditions, leading to better-informed designs.

- Construction: During the construction phase, BIM minimizes clashes between different systems—mechanical, electrical, and plumbing—by offering detailed, integrated models. This leads to fewer on-site modifications and smoother workflows.

- Operation and Maintenance: One of the biggest advantages of BIM in the oil and gas industry is its use in managing operations and maintenance. With up-to-date as-built models, operators can easily identify the location of components, reducing downtime for repairs and improving overall efficiency.

- Decommissioning: Even when it comes to decommissioning oil and gas facilities, BIM proves invaluable. With detailed historical records and as-built documentation, the process becomes safer and more cost-effective.

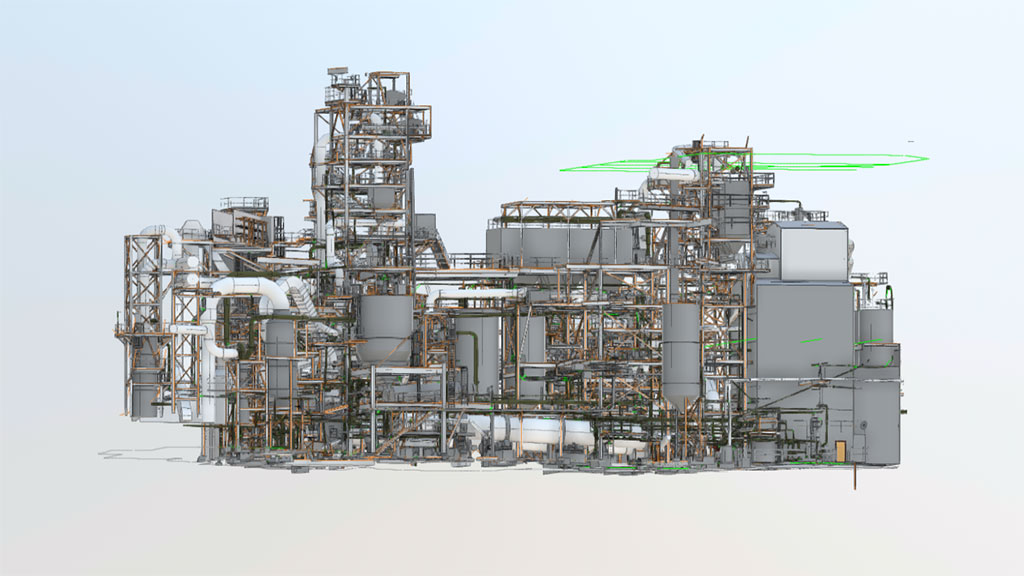

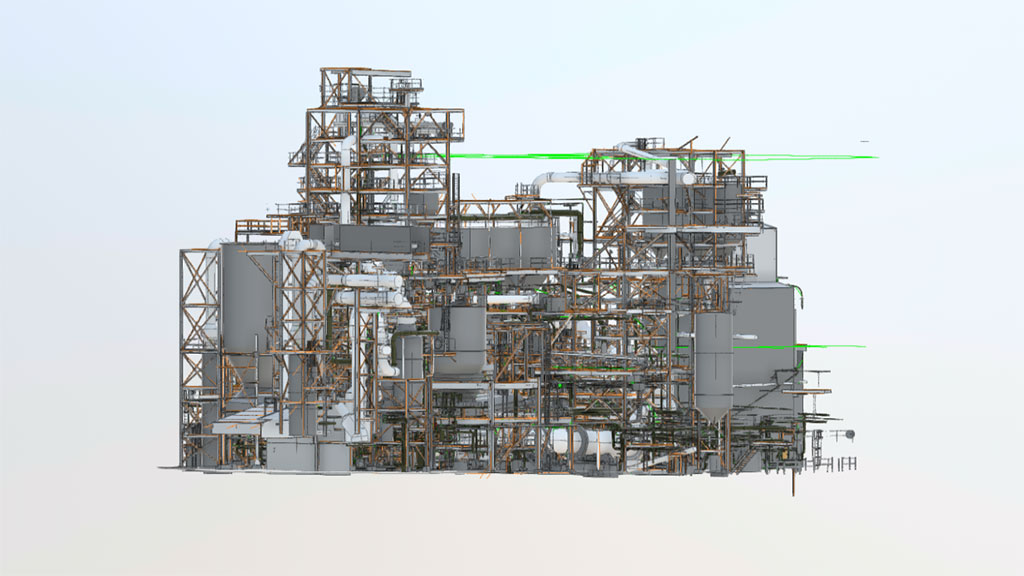

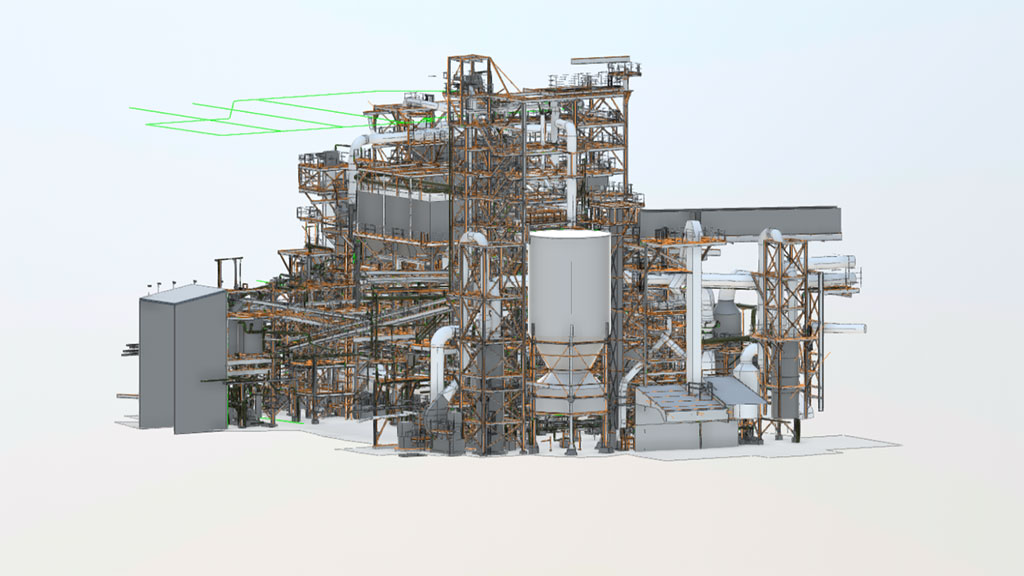

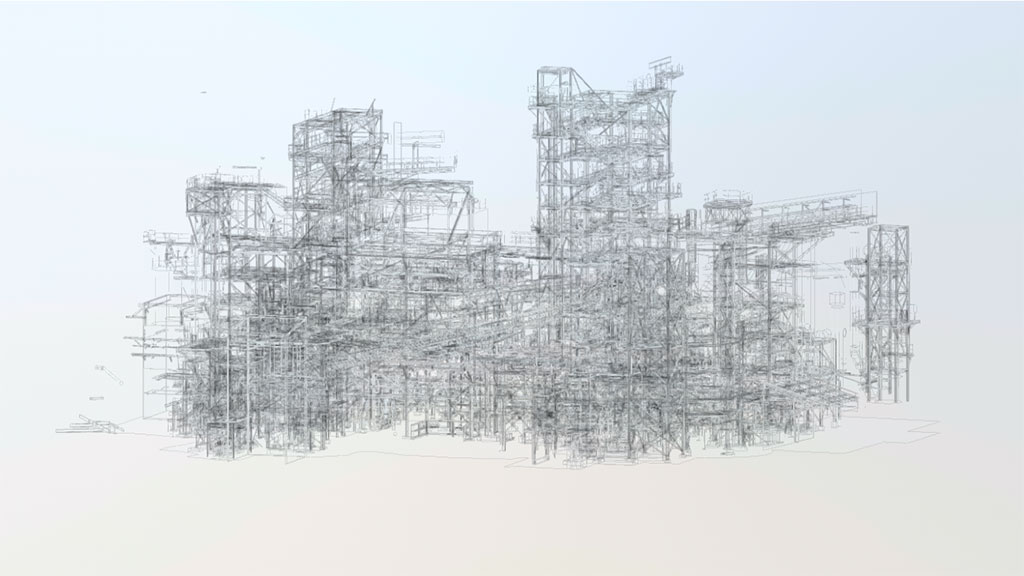

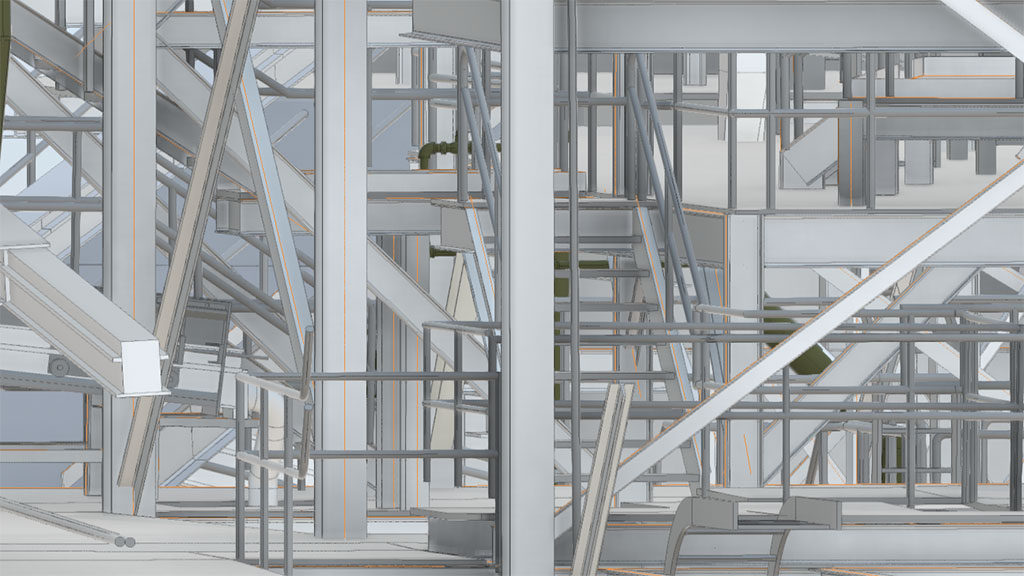

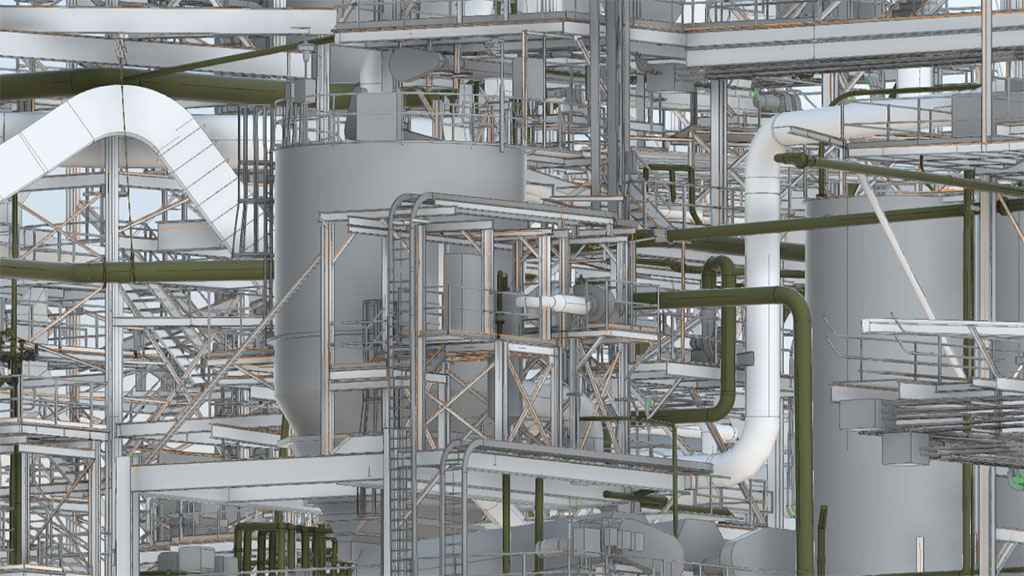

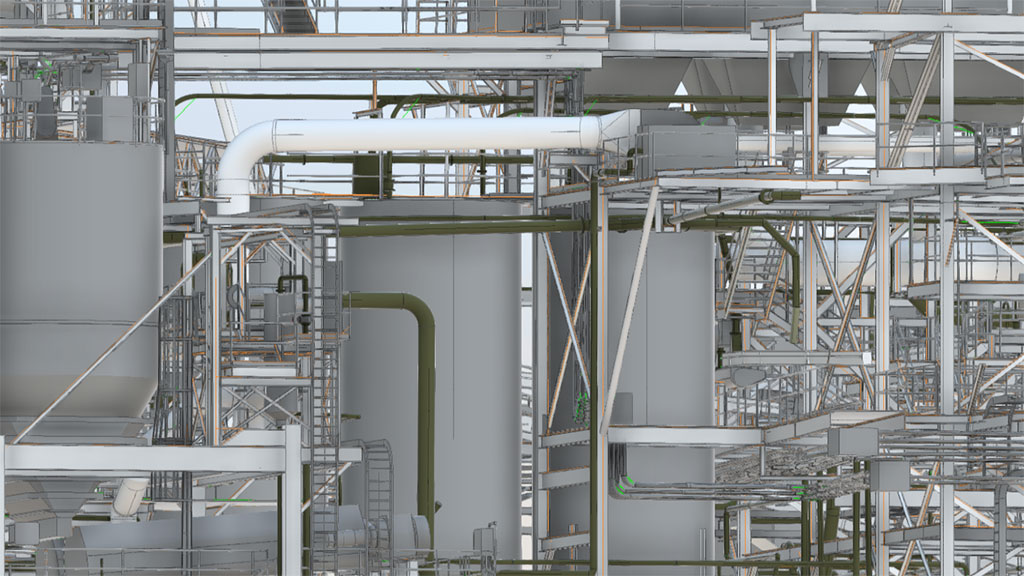

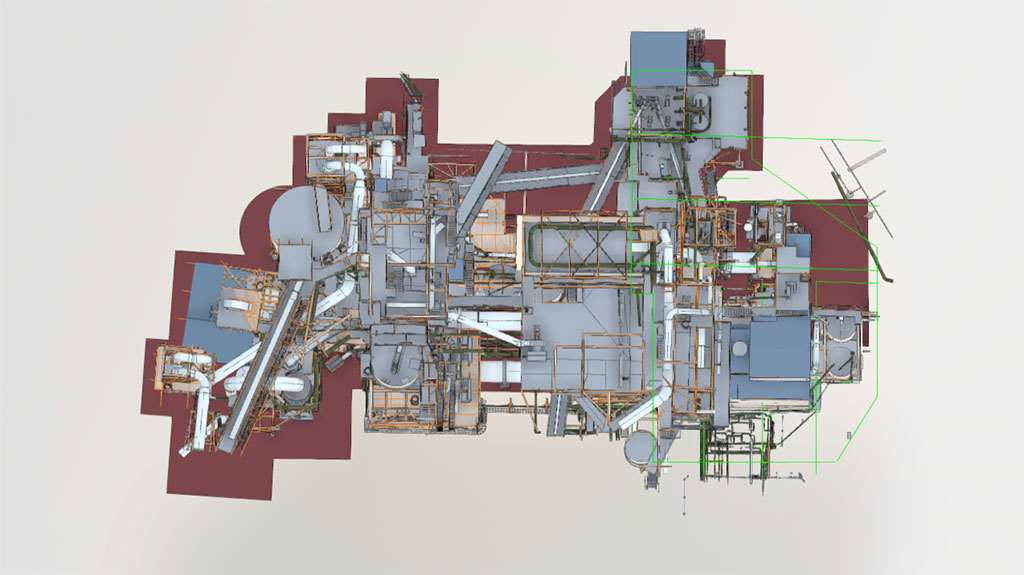

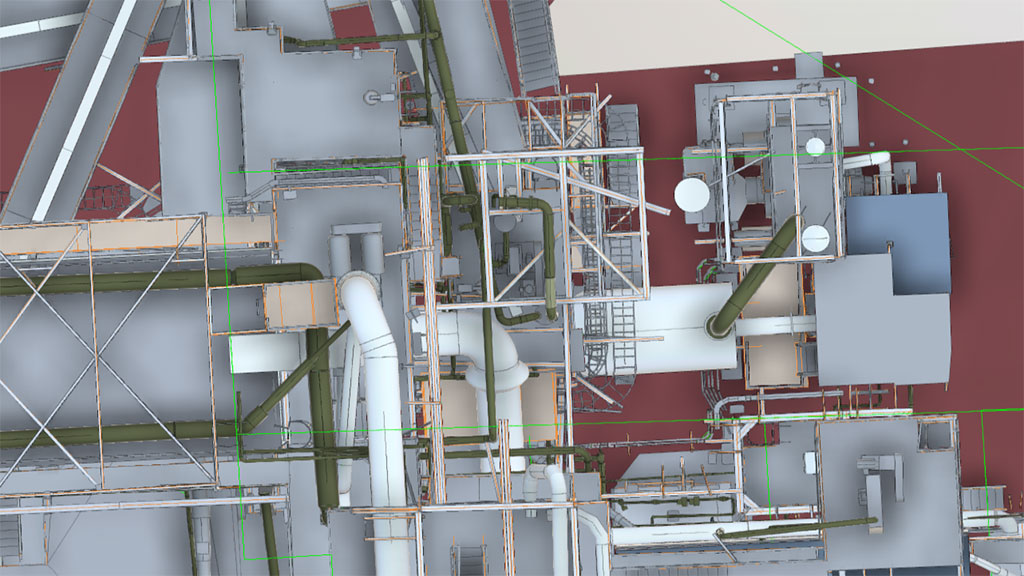

Our BIM Model of Oil Factory

We can scan and create a BIM model anywhere in the world. Let’s Get in touch!

BIM Oil and Gas: Key Technologies and Processes

The integration of BIM in oil and gas facilities involves a combination of cutting-edge technologies and processes that significantly improve accuracy and efficiency.

3D Laser Scanning and As-Built Models

3D laser scanning has become a cornerstone of modern BIM projects, especially in the oil and gas industry. This technology captures the current state of a facility with incredible precision, creating a point cloud that forms the basis for an as-built model. This model is then used to develop the BIM design, ensuring that every component of the facility is accurately represented.

The resulting as-built documentation is crucial not only for construction purposes but also for future inspections, repairs, and expansions. In industries like oil and gas, where safety and regulatory compliance are paramount, having accurate as-built models is a non-negotiable aspect of facility management.

Clash Detection and Risk Mitigation

One of the most critical features of BIM is its ability to detect clashes before construction even begins. In a BIM oil and gas model, engineers can visualize potential conflicts between systems—whether it’s between a pipeline and an electrical conduit or structural beams. By addressing these issues early, BIM helps avoid expensive rework and reduces the risk of safety incidents, which is particularly important in high-risk environments like oil and gas facilities.

As-Built Documentation and CAD Integration

Upon project completion, BIM delivers comprehensive as-built documentation that reflects the facility’s actual state. This documentation often includes detailed CAD drawings, 3D models, and survey data, which operators can use for asset management and future maintenance. With this information in hand, oil and gas companies can significantly improve the efficiency of their operations.

Applications of BIM in Oil and Gas Projects

BIM technology finds application in several critical areas within the oil and gas industry:

- Refinery Design and Maintenance: Refineries are complex structures with intricate piping and machinery. BIM helps operators create a virtual model that ensures all components fit together without conflict. This model can then be updated as changes occur, ensuring that as-built models are always current.

- Offshore Platforms: Offshore oil rigs are some of the most challenging environments for construction and maintenance. BIM improves efficiency by providing a detailed model that can be used for planning everything from daily operations to emergency evacuations.

- Pipeline Networks: Managing the installation and maintenance of extensive pipeline networks is simplified through BIM models that provide real-time data on the location, material, and condition of pipes, helping to optimize operations and prevent leaks or failures.

The Future of BIM in the Oil and Gas Industry

The growing adoption of BIM in oil and gas signals a shift toward smarter, more integrated infrastructure management. As the industry continues to face challenges like volatile prices and stricter environmental regulations, BIM will play an increasingly important role in helping companies navigate these obstacles. By providing better planning tools, improved safety protocols, and more efficient maintenance solutions, BIM oil and gas projects will set the standard for how infrastructure is designed, built, and managed in the future.

Furthermore, as digital twins—a key feature of BIM—become more sophisticated, oil and gas companies will be able to simulate every aspect of their operations in real-time, leading to better decision-making and more proactive maintenance strategies. This technology will not only improve profitability but also contribute to the sustainability of oil and gas operations by reducing waste and lowering the carbon footprint of new projects.

Conclusion

The implementation of BIM in the oil and gas industry is transforming how companies plan, design, and manage their infrastructure. By offering a comprehensive digital model that integrates every aspect of a facility’s lifecycle, BIM improves safety, reduces costs, and enhances operational efficiency. With the ability to capture accurate data through 3D laser scanning, create precise as-built models, and facilitate better decision-making, BIM oil and gas solutions are essential for the future success of the industry.

FAQs About BIM in Oil and Gas

What is BIM in the oil and gas industry?

Building Information Modeling (BIM) is a digital process that creates detailed models to manage the design, construction, and operation of complex oil and gas infrastructures.

Why is BIM important for the oil and gas sector?

BIM improves efficiency, reduces costs, enhances safety, and provides a comprehensive model for managing every aspect of an oil or gas facility’s lifecycle.

How does BIM differ from traditional CAD drawings?

While CAD drawings focus on two-dimensional designs, BIM incorporates 3D modeling and integrates information about materials, schedules, and costs, providing a more comprehensive view of the project.

What role does 3D laser scanning play in BIM for oil and gas?

3D laser scanning captures the existing conditions of a facility with precision, which is then used to create an accurate as-built model. This model forms the basis for the BIM design process.

What are the main software programs used for BIM in oil and gas?

Key programs include Autodesk Revit, Navisworks, and Bentley Systems, which allow for detailed modeling, clash detection, and as-built documentation.

How can BIM reduce costs in oil and gas projects?

By detecting clashes early, providing accurate data, and improving project coordination, BIM reduces the need for costly rework and optimizes resource management.