Structural Design of Buildings Under Real Project Constraints

In real projects, the structural design process breaks down when layout decisions are made before architectural grids, shafts, and major openings are stable. Most structural issues are not caused by incorrect calculations, but by decisions taken earlier than the available data and coordination maturity allow.

For structural engineers, BIM managers, and project coordinators, the structural design process is primarily about defining what information can be relied on, at which stage, and with what level of responsibility.

Structural Design Decisions Are Only as Reliable as Their Deliverables

Structural design reliability depends on whether structural intent is consistently reflected across the analysis model, issued drawings, and coordinated BIM model. These are not interchangeable representations; each carries a different level of technical and contractual responsibility.

Problems arise when:

- analysis models are updated without re-issuing drawings,

- coordination models change without validation against approved analysis,

- construction relies on information never issued for execution.

In renovation projects, these gaps are amplified by incomplete or contradictory as-built documentation.

Structural Layout: Early Decisions with Long-Term Consequences

Structural layout defines grids, spans, load paths, and system hierarchy. Once these decisions are locked into the analysis model, later changes typically require reworking load paths, recalculating member sizes, updating drawings, and repeating coordination with architecture and MEP.

Typical project failure scenarios include:

- architectural layouts evolving after structural grids are fixed,

- vertical shafts introduced after load paths are defined,

- transfer structures sized using outdated geometry.

At this point, even minor architectural changes propagate through multiple structural deliverables.

Structural Design Process Defined by Coordination Checkpoints

In practice, the structural design process is governed by coordination checkpoints rather than formal phases. At each checkpoint, engineers must verify whether inputs are sufficiently stable to support binding decisions.

Critical checkpoints usually include:

- alignment of structural grids with architectural layouts,

- confirmation of major openings and shafts,

- validation of load paths before detailed analysis,

- consistency between analysis results and issued drawings.

When these checkpoints are missed, analysis may remain technically correct while becoming unusable for construction.

Structural Design Analysis and Its Practical Limits

Structural design analysis verifies strength and serviceability, but analysis models depend on assumptions that often lag behind coordination changes. Boundary conditions, stiffness assumptions, and tolerances are rarely updated at the same pace as architectural or MEP revisions.

Common breakdowns occur when:

- architectural changes are not reflected in the analysis model,

- MEP routing alters load paths without structural validation,

- updated as-built information is ignored.

Without explicit linkage to coordination checkpoints, analysis results lose relevance for execution decisions.

Structural Design Drawings as the Primary Construction Reference

Structural design drawings define what is actually built. They carry contractual weight and must reflect the latest coordinated state of the project.

Failures typically occur when:

- drawings lag behind coordination updates,

- analysis changes are not re-issued,

- details are produced without reviewing construction sequencing and tolerances.

In practice, unclear responsibility for drawing updates causes more site issues than incorrect calculations.

CAD vs BIM: Difference Defined by Accountability

| Aspect | CAD-Based Delivery | BIM-Based Delivery |

|---|---|---|

| Primary reference | Issued drawings | Issued model + drawings |

| Change control | Manual tracking | Model governance required |

| Typical failure | Drawing inconsistency | Model used beyond its approval level |

| Construction risk | Late clashes | False confidence in unvalidated models |

In practice, this requires clearly defined BIM deliverables, coordination checkpoints, and model approval rules, typically formalized through dedicated BIM services focused on coordination and documentation control.

BIM does not reduce risk by itself. Risk is reduced only when deliverable boundaries, update responsibility, and approval status are clearly defined.

Steel Structure Design: Accuracy as a Hard Constraint

Steel structure design operates under strict accuracy limits. Prefabrication and connection detailing require geometry that is both coordinated and validated.

In practice this means:

- model accuracy often within ±2 mm,

- fabrication-level detailing at early stages,

- minimal tolerance for late coordination changes.

Any mismatch between issued drawings and coordination models propagates directly into fabrication and site errors.

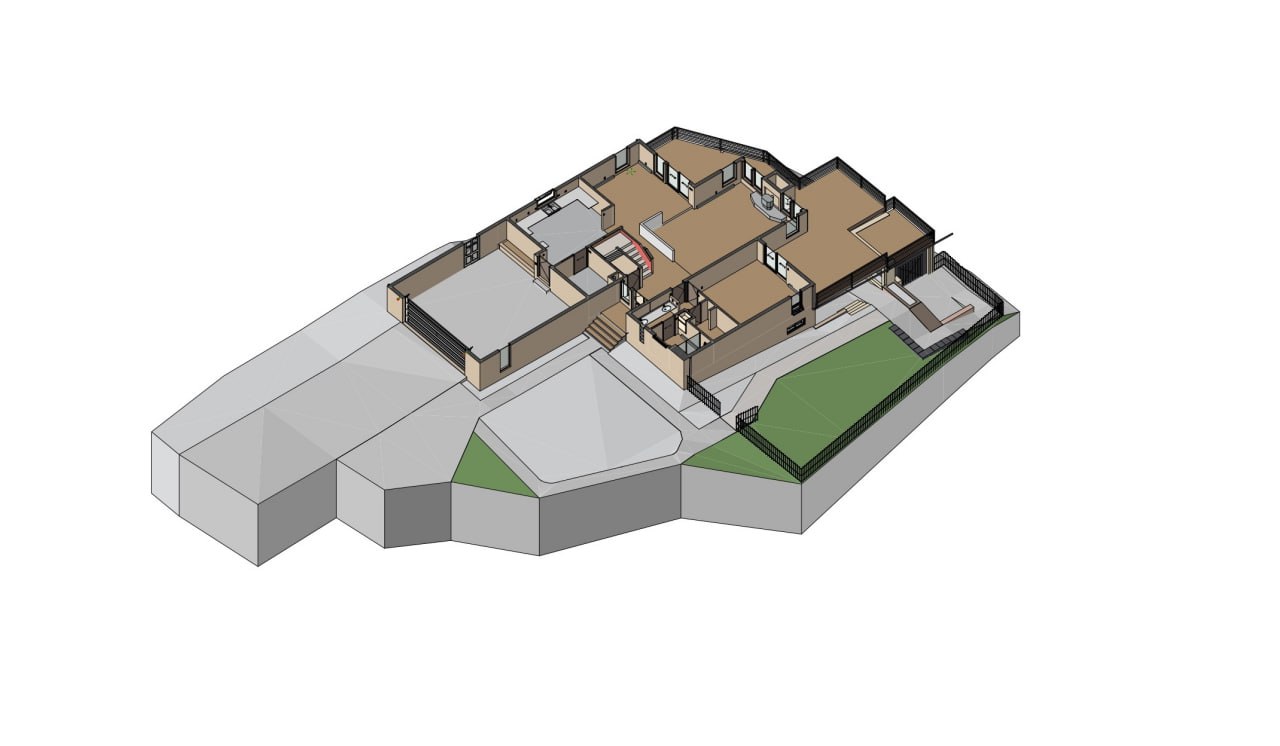

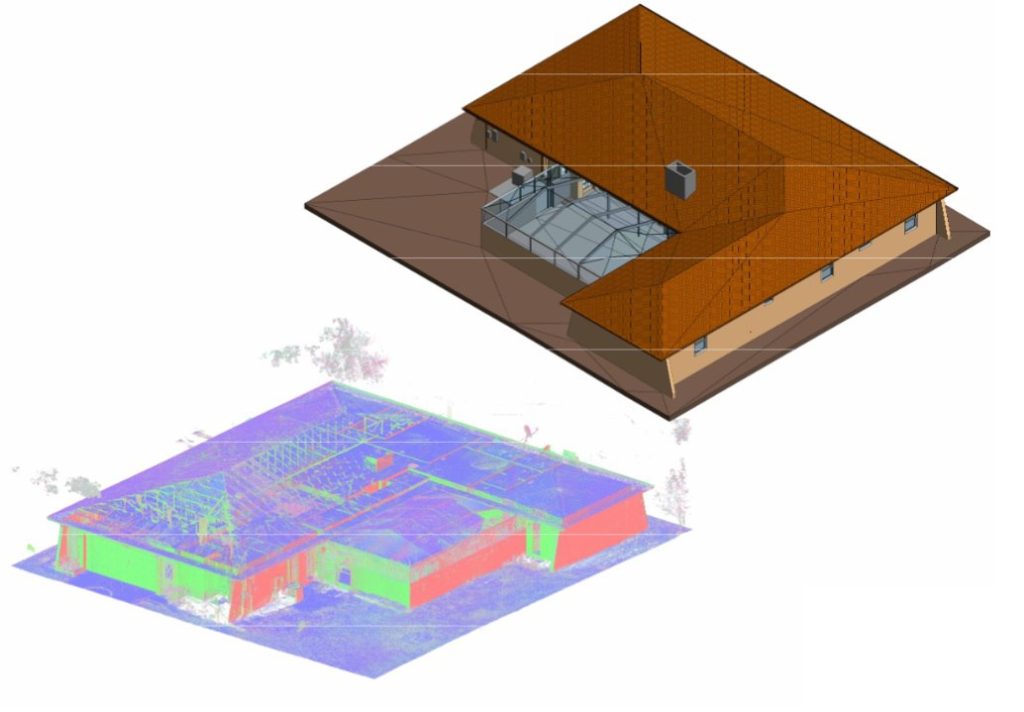

Scan to BIM as an Engineering Baseline

In existing buildings, Scan to BIM defines the geometric and structural baseline for design assumptions. Its value lies not in data volume, but in controlled reliability.

Engineering risks arise when:

- point clouds are simplified without structural verification,

- load-bearing elements are assumed rather than confirmed,

- coordination models diverge from issued documentation.

Scan to BIM defines the limit of reliability for structural decisions, not merely the source of geometry.

Typical Structural Design Risks in Real Projects

Recurring risks across AEC projects include:

- analysis models disconnected from issued drawings,

- structural layouts inconsistent across levels,

- late discovery of broken load paths,

- reliance on outdated or unverified as-built data.

These issues result from process gaps and unclear responsibility, not from software limitations.

Practical Engineering Takeaways

Structural design of buildings is governed by coordination discipline and deliverable accountability. Calculations, BIM models, and drawings are tools whose value depends on timing, validation, and ownership.

Projects perform reliably when:

- design decisions align with coordination maturity,

- analysis is tied to verified inputs,

- issued documentation reflects construction reality.

Managing these constraints is the core task of modern structural engineering.

What causes most structural design failures?

Decisions made beyond the reliability of available inputs.

Why do drawings and models diverge?

Because update responsibility and coordination checkpoints are unclear.

Does BIM eliminate coordination errors?

No. BIM exposes them earlier if governance is enforced.

Why is Scan to BIM critical for renovations?

Because it defines the boundary between verified and assumed conditions.

Read more:

- How As-Built Drawings Are Created: Step-by-Step Process

- BIM Level of Detail Explained: When More Detail Stops Adding Value

- Shop Drawings vs As-Built Drawings — Meaning, Differences, Examples & Complete Guide

- Using Drones and Laser Scanning for As‑Built Surveys

- Top 5 Benefits of 3D Laser Scanning for Interior Design