What is Reverse Engineering and How Does It Support Production?

What Does Reverse Engineer Mean?

Many engineers and manufacturers ask: what is reverse engineering and what does reverse engineer mean in practice? In simple terms, reverse engineering is the method of studying an existing object, scanning its geometry, and recreating a precise digital model. It answers the question what does it mean to reverse engineer something — it means transforming a physical component back into technical documentation and CAD data.

This is why many companies rely on reverse engineering services in US: it ensures continuity of production, modernization of equipment, and precision in design.

What is the Reverse Engineering Process?

When people search for reverse engineering what is it or what is the reverse engineering process, they usually want to understand the step-by-step workflow. The process typically includes four stages:

- Geometry Digitization

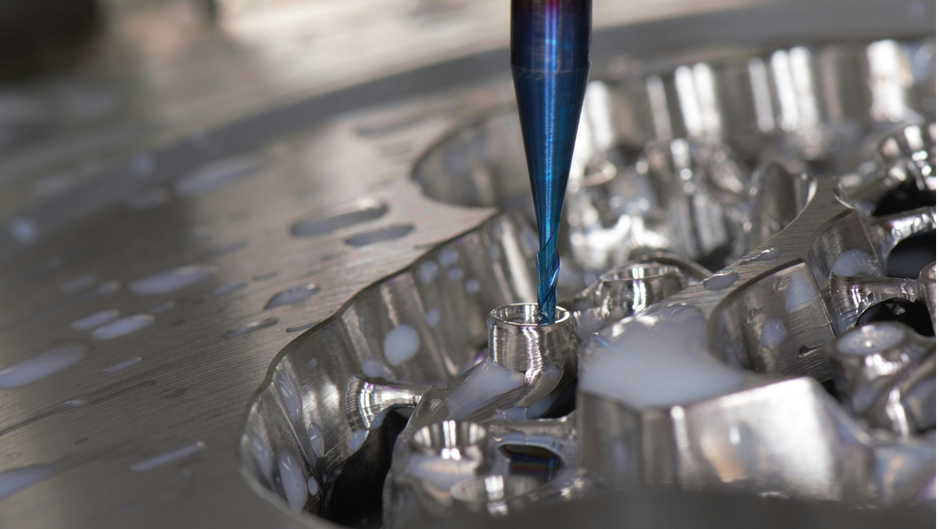

Laser scanners capture millions of points per second, generating a detailed point cloud. This makes it possible to reproduce even the most complex shapes. - Data Processing

Specialized software cleans up the scans, merges them, and creates a 3D mesh. Key features such as holes, edges, and planes are automatically recognized. - CAD Model Reconstruction

Based on the point cloud, engineers build a CAD model. This answers the question what is meant by reverse engineering — it is the transformation of real-world geometry into editable, standardized design data. - Verification and Implementation

The model can be validated with FEM simulations and then used for CNC machining or 3D printing. This is the reverse engineering process in its practical form.

What is the Purpose of Reverse Engineering?

The next common question is what is the purpose of reverse engineering. The main goals include:

- Reproducing lost or undocumented components.

- Modernizing existing designs to extend machine lifespan.

- Creating spare parts without stockpiling large inventories.

- Supporting innovation by redesigning and improving products.

- Ensuring independence from imports by manufacturing compatible parts locally.

In short, what does it mean to reverse engineer in industry? It means turning challenges like missing documentation or obsolete suppliers into opportunities for continuity and improvement.

Modern Applications of 3D Scanning in Reverse Engineering

According to a MarketsandMarkets (2023) report, the reverse engineering market is expected to reach $8.1 billion by 2027. Key trends include:

- Digital Twin – Creating digital twins of machines that integrate with IoT systems, enabling real-time monitoring and analysis.

- AI-Driven Redesign – Using artificial intelligence algorithms for automatic geometry optimization and improving design parameters.

- Metrology 4.0 – Integrating 3D scanners with Manufacturing Execution Systems (MES) to automate quality control and engineering processes.

What is the Meaning of Reverse Engineering in Industry?

When discussing what is the meaning of reverse engineering, it’s important to note that it does not simply copy parts. Instead, it provides a way to analyze, optimize, and redesign components for Industry 4.0. Examples include:

- Aerospace — reproduction of turbine blades with 0.05 mm accuracy.

- Medical — scanning and adapting implants for better patient integration.

- Energy — reconstruction of pump rotors with minimal error tolerance.

- Construction — creating as-built documentation for structural elements.

What are some examples of reverse engineering

- Aerospace: Reproduction of a Rolls-Royce Trent XWB turbine blade made from ceramic composite, reducing operating temperature by 150°C.

- Medical: Scanning of bone implants and modification of surface porosity for better osseointegration.

- Energy: Reconstruction of heat pump rotors with an error margin below 0.03 mm.

Legal Considerations: When Is Reverse Engineering Permitted?

While reverse engineering offers numerous technological and business advantages, it’s essential to be mindful of the legal aspects. Such practices are only allowed under certain conditions, for example when:

- you fully own the part and are using it for internal purposes,

- the original manufacturer no longer exists or has discontinued support and availability,

- the component being reproduced is not protected by a patent, trade secret, or industrial design rights,

- the process is conducted for educational or research and development purposes, without bringing the copied product to market.

It’s always recommended to consult with an intellectual property lawyer before starting any reverse engineering project — especially if the results are intended for commercial use.

Why Implement Reverse Engineering?

Reverse engineering is an invaluable tool for optimizing processes, reducing costs, and supporting sustainable development in industry and other sectors. The key benefits include:

- Extending Machine Lifespan by 20–30 Years

Thanks to digital replication and modernization of parts, old equipment gains a “second life.” - Reducing Storage Costs by up to 60%

Reverse engineering eliminates the need to stockpile large inventories of spare parts. In case of failure, the component is reproduced on demand, minimizing downtime and logistics costs. - Supporting the Circular Economy

Reverse engineering enables “design recycling” – analyzing worn components for enhancement, reuse, or replacement with eco-friendly alternatives. - Independence from Imports and Quality Control

It allows for reproducing parts of foreign machines without needing to purchase original components, which is crucial for import substitution. Additionally, 3D scanning and digital analysis help detect manufacturing defects.

In the era of rapid technological advancements, many companies face “technological blind spots” – missing documentation, outdated components, or unavailable suppliers.

Reverse engineering not only solves these problems but also opens the door to innovation: the reproduced element can be improved, adapted to new standards, or integrated with digital Industry 4.0 systems.

FAQ

What is reverse engineering?

It is the process of analyzing an existing part or product and recreating its digital model for design, production, or improvement.

What does reverse engineer mean?

It means to study how something was built and convert it into technical data or a CAD model.

What does it mean to reverse engineer something?

It means taking a finished object, capturing its geometry, and rebuilding a usable design model.

What is meant by reverse engineering?

It is a method to transform real objects into digital data for manufacturing, repair, or redesign.

What is reverse engineering process?

The process includes scanning geometry, processing data, reconstructing CAD models, and verifying results.

What is the meaning of reverse engineering?

The meaning is to bridge the gap between physical objects and digital innovation.

What is the purpose of reverse engineering?

Its purpose is to extend equipment lifespan, reduce costs, and support innovation in production.

Conclusion

So, what is reverse engineering? It is the bridge between existing physical objects and future innovation. Whether the goal is to reduce costs, extend the life of machines, or improve product design, reverse engineering provides the tools to achieve it.

If your company is searching for the best reverse engineering services in the US, ScanM2 delivers precision, speed, and reliability.