Accurate documentation is vital in construction and architecture, especially when it comes to as-built drawings. These documents capture the final state of a building after construction, serving as a reliable reference for renovations, maintenance, and compliance. In this article, we’ll explain what as-built drawings are, how they differ from original plans, and how modern tools like BIM and 3D scanning enhance their accuracy and usefulness.

What Are As-Built Drawings?

As-built drawings (sometimes called record drawings or as-constructed drawings) represent the final, verified design of a building or structure after construction has been completed. These drawings reflect any changes made during the construction phase, deviations from the original design, and any modifications implemented to meet field conditions.

While the original architectural and engineering plans provide the initial vision for a structure, as-built drawings capture the actual, completed state of the project. These documents capture all modifications made throughout the construction process, including any changes from the original design and adjustments made to accommodate site-specific conditions.

Here are the key elements of as-built drawings:

- Real Dimensions: As-built drawings reflect the exact dimensions of a structure, including all the modifications that occurred during the construction process. This could include repositioning walls, doors, and windows, or even revising the layout of mechanical systems.

- Material Specifications: The drawings include detailed information on materials used throughout the construction. This can include variations from the original plans, such as different materials used for flooring, walls, or structural elements.

- Construction Changes: Any changes made to the initial design due to site conditions, client requests, or unforeseen issues are recorded. These may include alterations to structural components, layout adjustments, or modifications to electrical or plumbing systems.

- Installation and Systems Details: As-built drawings include the precise locations of all installed systems, such as electrical wiring, HVAC systems, plumbing, and other utilities. This ensures that maintenance teams can easily locate and service these systems in the future.

Why Are As-Built Drawings Important?

As-built drawings play a critical role throughout the life cycle of a building. They provide a record of the completed structure, making them essential for future work, whether it be maintenance, renovations, or expansions. Here are the key reasons why as-built drawings are important:

1. Future Renovations and Maintenance

As-built drawings provide crucial information for anyone looking to make changes to the building in the future. Whether it’s a renovation, extension, or repair, having accurate as-built drawings ensures that future work can be performed without damaging the existing structure or systems.

2. Construction Verification and Compliance

As-built drawings serve as proof that the project was completed according to the specifications approved by regulatory bodies. They verify compliance with building codes and regulations, ensuring the project meets all legal and safety standards.

3. Facility Management and Operations

For facility managers and owners, as-built drawings are vital tools for managing the building. They provide accurate details about the building’s systems and layout, making it easier to plan for routine maintenance, emergency repairs, or system upgrades.

4. Dispute Resolution

In cases of disputes related to construction, as-built drawings can serve as a legal document. They provide an official record of what was actually constructed, which can be crucial in resolving conflicts between contractors, clients, or regulatory authorities.

Learn more about how accurate as-built documentation improves engineering workflows in our article on

How Are As-Built Drawings Created?

Creating accurate as-built drawings involves several steps. The process typically begins after the construction is completed, and it includes a detailed verification of the structure’s dimensions and systems. Here is an overview of the steps involved:

1. Field Verification

The first step in creating as-built drawings is a field survey, where professionals visit the site to measure and document the actual dimensions of the building. This involves measuring the placement of walls, doors, windows, ceiling heights, and other features. Field verification also includes documenting any changes made during the construction process.

2. Recording Changes and Modifications

During construction, changes are often made to the original plans due to unforeseen circumstances, design alterations, or client preferences. These modifications must be accurately recorded in the as-built drawings. The construction team will mark up the original design plans with details of all these changes, ensuring that the final drawings reflect the true state of the building.

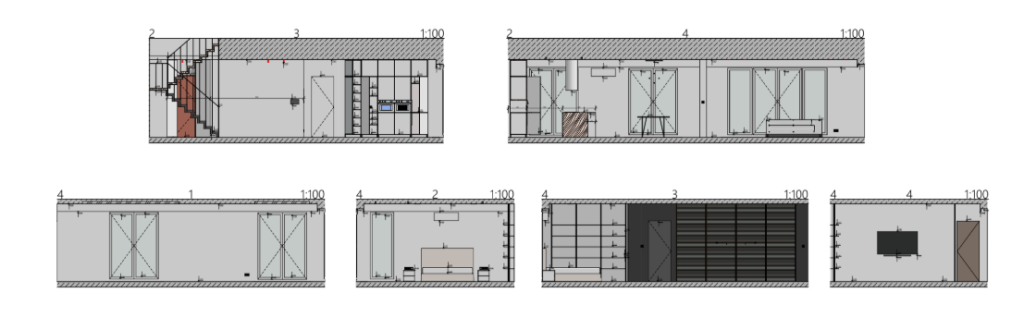

3. Creating the Drawings

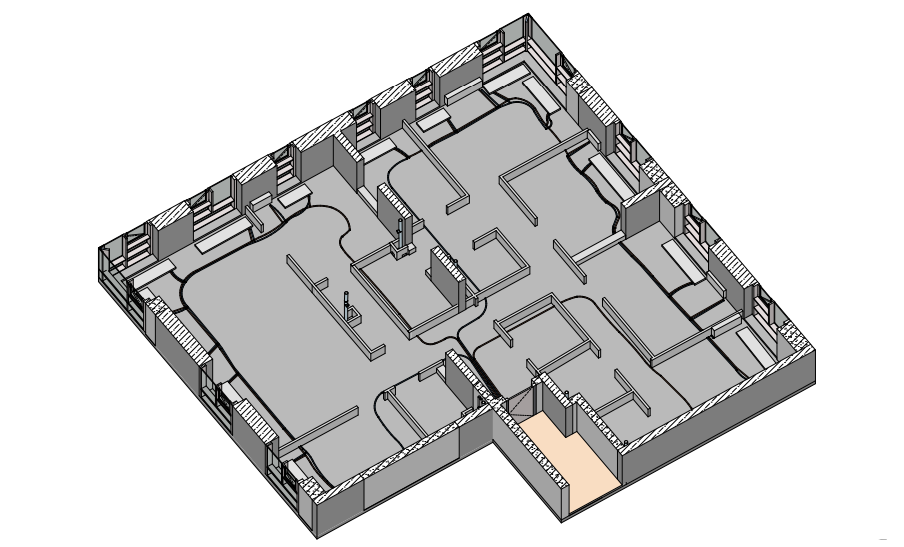

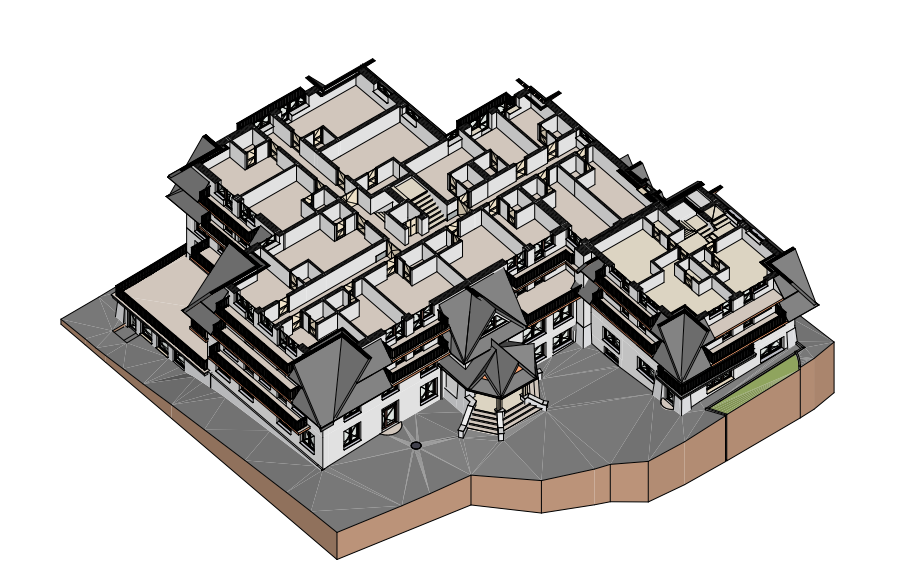

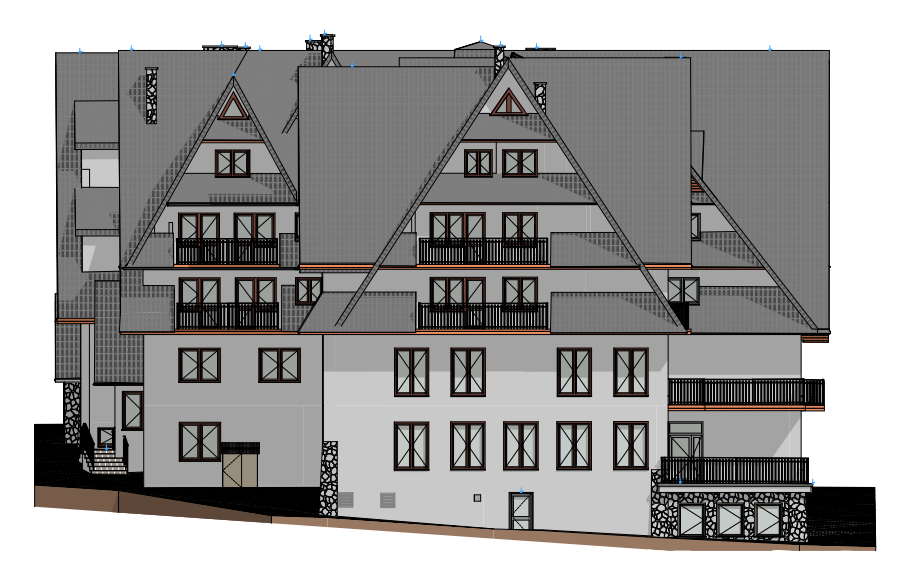

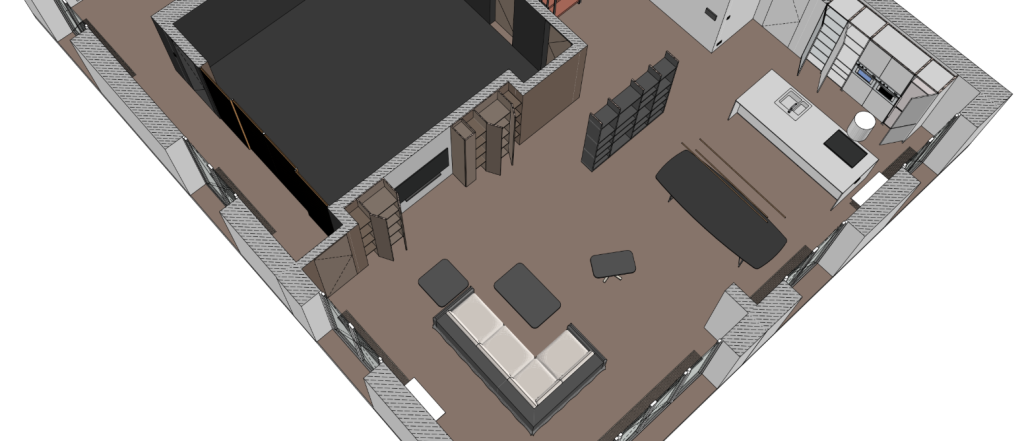

Once the field data is collected and all modifications are recorded, the as-built drawings are created. This can be done using traditional drafting methods or by using modern software tools such as AutoCAD. Many companies today use BIM (Building Information Modeling) to create digital, 3D representations of buildings. BIM allows for more accurate and detailed as-built models, making it easier to track changes and visualize the finished structure.

4. Review and Finalization

After the initial drawings are created, they are reviewed for accuracy and completeness. Any discrepancies or errors are corrected before the final version is approved. Once completed, the final as-built drawings are delivered to the client, relevant authorities, or any other stakeholders involved in the project.

The Role of Modern Technologies in As-Built Drawings

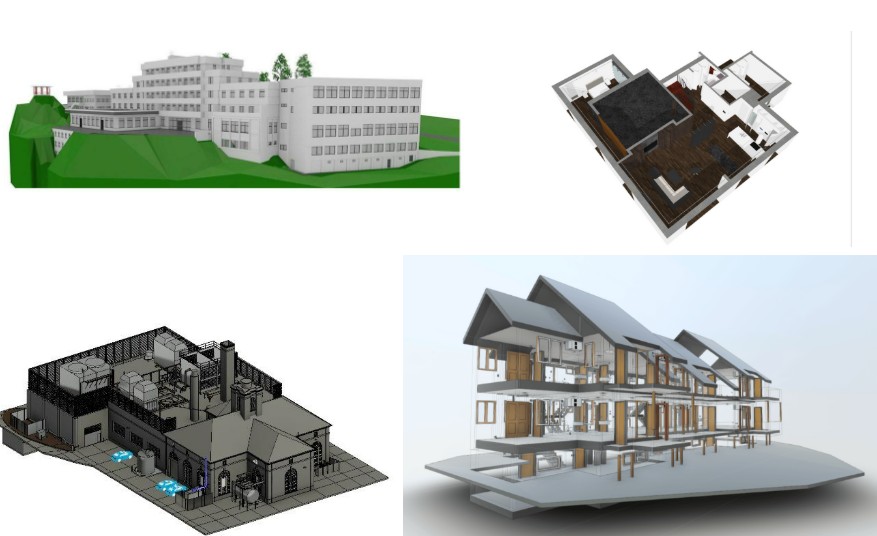

While traditional methods of creating as-built drawings still exist, modern technologies have revolutionized the process. Today, 3D scanning, BIM, and drone technology are commonly used to create highly accurate as-built drawings.

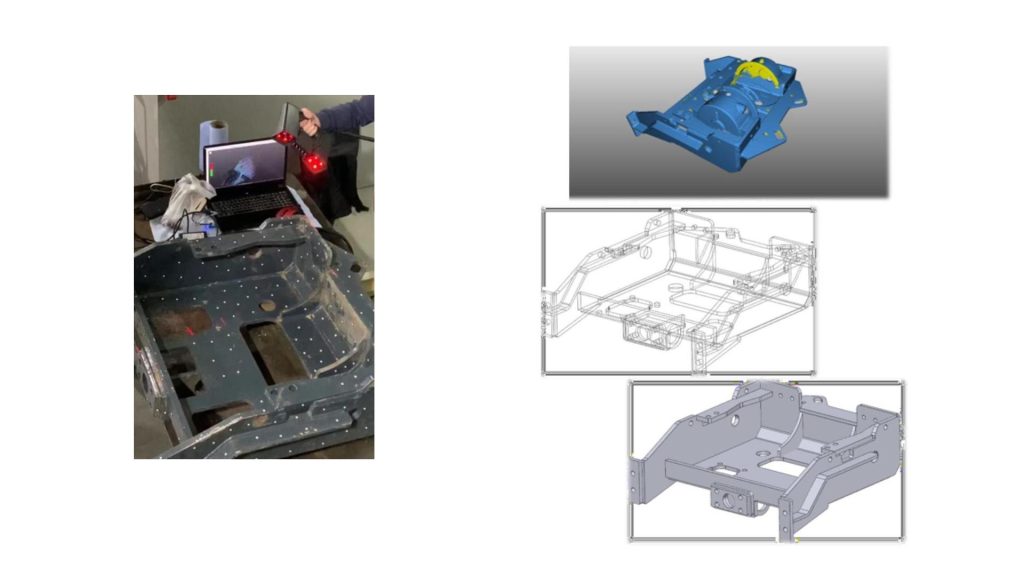

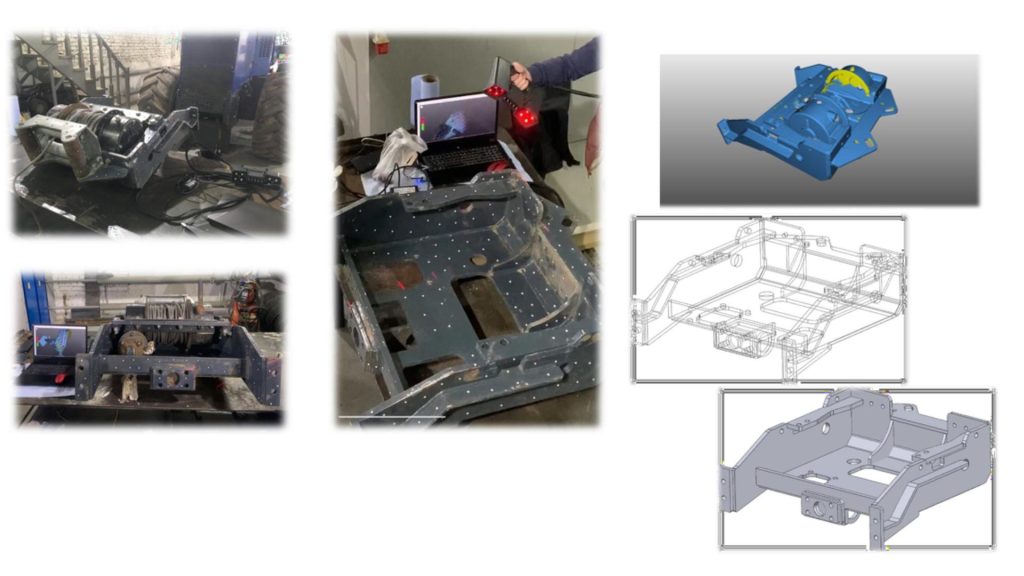

3D laser scanning is one of the most advanced methods used to create as-built drawings. A 3D scanner captures millions of data points to create a detailed, highly accurate 3D model of the building. The scanner’s laser technology provides precise measurements of every part of the structure, ensuring that the final as-built drawings are as accurate as possible. This technology significantly reduces the margin of error that can occur with manual measurement.

2. Building Information Modeling (BIM)

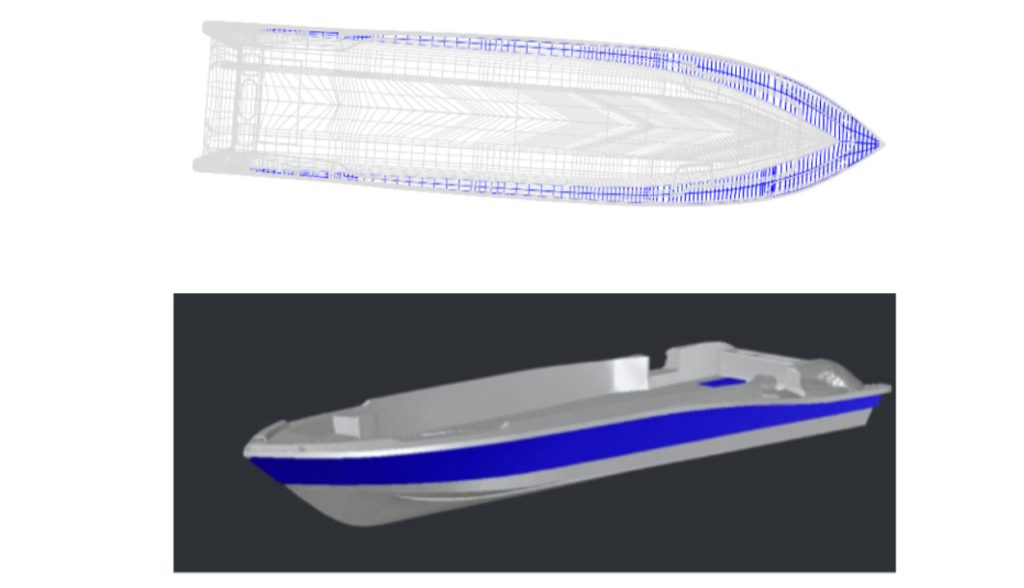

BIM is a digital representation of a building’s physical and functional characteristics. BIM allows architects, engineers, and contractors to create a detailed 3D model of the building, which can be updated throughout the construction process. Once construction is complete, the BIM model becomes the as-built model, reflecting all changes made during construction. BIM models can be easily shared among team members, making collaboration more efficient.

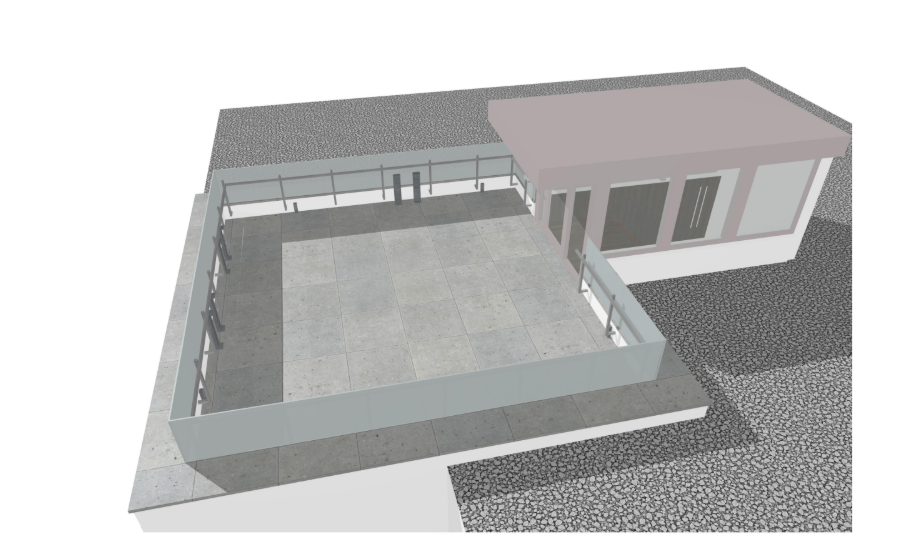

3. Drones and Aerial Mapping

Drones equipped with cameras and LIDAR (Light Detection and Ranging) sensors are becoming increasingly popular for capturing data on building sites. Drones can quickly scan large areas and generate 3D models of the building’s exterior. These models can then be integrated into the overall as-built drawings to provide a more comprehensive view of the completed project.

Differences Between As-Built Drawings and Original Design Plans

It is essential to understand how as-built drawings differ from the original design plans. Here are the key differences:

- Accuracy: Original design plans are based on the architect’s and engineer’s initial vision for the project. As-built drawings, on the other hand, reflect the actual construction, including any changes or deviations that occurred during the building process.

- Changes in Design: As-built drawings account for all modifications made during construction. If a wall was moved, materials changed, or a new system added, it is documented in the as-built drawing.

- Construction Process vs. Vision: Original plans are based on the theoretical vision of the building, while as-built drawings reflect what was physically constructed.

Conclusion

As-built documentation plays a crucial role in the construction workflow. They provide an accurate, up-to-date record of a building’s final form, including all modifications and changes made during construction. They serve as a critical reference for upcoming renovations, ongoing maintenance, and regulatory compliance. By utilizing modern technologies like BIM, 3D scanning, and drone mapping, creating as-built drawings has become more accurate, efficient, and easier to manage.

If you’re looking for accurate and reliable as-built drawing services, Scan M2 offers cutting-edge solutions using the latest technologies. Whether for new construction or existing buildings, we provide precise as-built documentation tailored to your project’s needs.