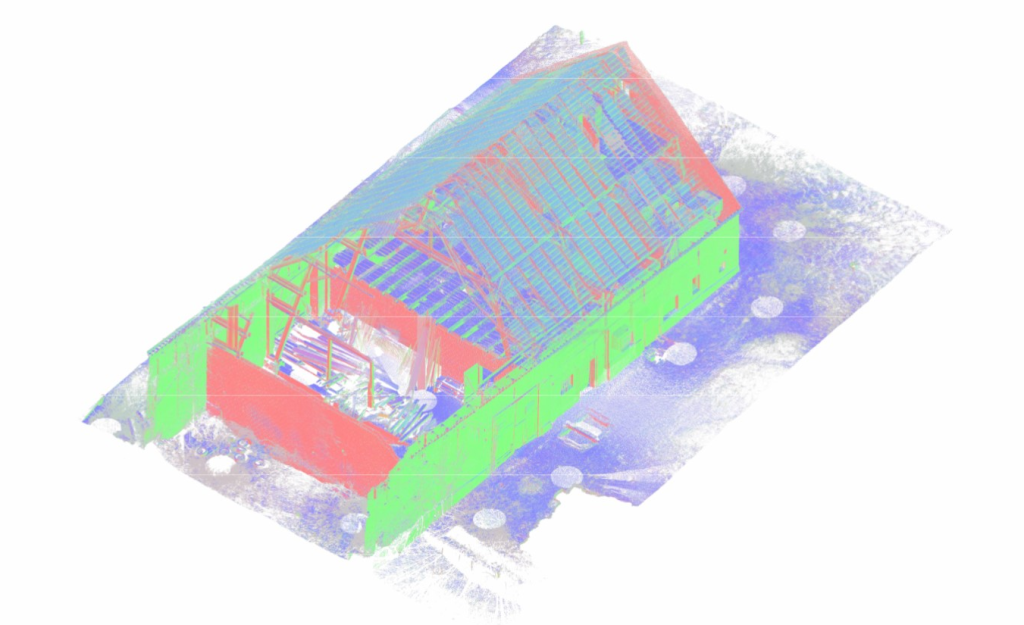

Laser Scanning Workflow from Site to Point Cloud

The laser scanning workflow is a structured and highly technical process that transforms raw field measurements into a precise digital model. A well-executed 3D laser scanning workflow ensures millimeter accuracy, reliable georeferencing, and a structured dataset ready for engineering, BIM, or design applications. Understanding the complete laser scanning process from site to point cloud — including the point cloud generation process within a terrestrial laser scanning workflow — is essential for achieving consistent, high-quality results.

Pre-Scan Planning and Site Preparation

A successful terrestrial laser scanning workflow begins long before equipment is deployed. Proper planning directly affects scan overlap, error margins, and overall quality control.

Key Steps in Pre-Scan Planning

- Define project scope and required accuracy

- Establish coordinate system setup

- Identify control points in laser scanning

- Plan scan station setup positions

- Determine scan overlap requirements

The coordinate system setup is critical for ensuring accurate georeferencing. Survey-grade control points in laser scanning are typically established using total stations or GNSS systems to maintain millimeter accuracy across large areas.

Target placement strategy is also determined at this stage. For target-based registration, reflective or spherical targets must be visible from multiple scan positions to enable accurate scan alignment later.

Careful planning reduces registration errors and simplifies the entire scan-to-cloud workflow.

Field Data Acquisition

The field scanning procedure is where site data acquisition begins. Each scan station setup must ensure sufficient scan overlap with adjacent positions to allow seamless registration.

Core Elements of Site Data Acquisition

- Stable tripod positioning

- Leveling and calibration of the scanner

- Capturing high-resolution scans

- Recording metadata and environmental conditions

- Verifying visibility of control targets

The scanner captures millions of points per second, generating a raw dataset that represents surfaces and structures. Adequate overlap (typically 20–40%) between scans ensures reliable cloud-to-cloud registration if target-based registration is not used.

Throughout site data acquisition, technicians perform real-time quality control checks to minimize blind spots and confirm coverage.

Scan Registration and Alignment

After fieldwork, the workflow transitions into laser scan data processing. The first major step is point cloud registration, where individual scans are combined into a unified coordinate framework.

Registration Methods

| Method | Description | Advantages | Use Case |

| Target-Based Registration | Uses physical targets captured in multiple scans | High precision, controlled alignment | Industrial & high-accuracy projects |

| Cloud-to-Cloud Registration | Uses geometric surface matching | Faster, fewer targets required | Complex environments |

| Hybrid Approach | Combines both methods | Improved reliability | Large-scale infrastructure |

Scan alignment ensures that overlapping areas match within acceptable error margins. Software calculates residual errors and reports deviation values for quality control.

When required, the dataset undergoes georeferencing, linking the project to real-world coordinates. This step is essential for infrastructure, construction, and urban planning projects.

Data validation is performed to confirm alignment accuracy and consistency across the entire structured dataset.

Point Cloud Cleaning and Validation

Once scans are aligned, the point cloud generation process continues with cleaning and optimization.

Cleaning Process Includes:

- Noise filtering in point cloud

- Removing stray reflections and moving objects

- Eliminating duplicate or misaligned points

- Reducing unnecessary density

Noise filtering in point cloud processing improves clarity and reduces file size while maintaining millimeter accuracy.

After cleaning, a second round of quality control and data validation ensures that:

- Error margins remain within project tolerance

- No gaps compromise deliverables

- The dataset meets required standards

A properly validated structured dataset is now ready for engineering applications.

Delivering Structured Data for Design

The final stage of the scan-to-cloud workflow converts the processed data into usable deliverables.

Common outputs include:

- Registered point cloud files (E57, RCP, LAS)

- Georeferenced datasets

- BIM-ready models

- CAD drawings

- Mesh models

The completed 3D laser scanning workflow results in a highly accurate digital representation of the physical environment. When executed correctly — from site data acquisition through scan alignment, data validation, and structured dataset delivery — the laser scanning workflow ensures reliable, precise information for design, renovation, analysis, and construction.

Conclusion

The laser scanning process from site to point cloud is not simply about capturing data — it is about managing precision at every stage. From coordinate system setup and control points in laser scanning to scan overlap management and cloud-to-cloud registration, each step contributes to overall data integrity.

A well-structured terrestrial laser scanning workflow guarantees millimeter accuracy, controlled error margins, and dependable results — transforming raw field measurements into actionable digital intelligence.

FAQ – Laser Scanning Workflow from Site to Point Cloud

What is a laser scanning workflow?

A laser scanning workflow is the complete process that transforms raw field measurements into a structured digital point cloud. It includes pre-scan planning, site data acquisition, scan registration, scan alignment, noise filtering in point cloud processing, and final data validation.

What is included in a 3D laser scanning workflow?

A typical 3D laser scanning workflow includes:

-

- Coordinate system setup

-

- Control points in laser scanning

-

- Field scanning procedure

-

- Scan station setup

-

- Point cloud registration

-

- Cloud-to-cloud or target-based registration

-

- Georeferencing

-

- Quality control and error margin verification

The goal is to produce a structured dataset with millimeter accurac

How does the laser scanning process from site to point cloud work?

The laser scanning process from site to point cloud starts with site data acquisition using terrestrial laser scanners. Multiple scans are captured with sufficient scan overlap. Then, laser scan data processing begins, where scans are aligned and registered. After cleaning and noise filtering, the final point cloud generation process delivers a validated and georeferenced dataset.

What is point cloud registration?

Point cloud registration is the process of combining multiple scans into a single coordinate system. This can be done using:

-

- Target-based registration (using physical reference targets)

-

- Cloud-to-cloud registration (surface matching algorithms)

Accurate scan alignment ensures minimal error margins and high-quality results.

Why is scan overlap important?

Scan overlap allows software to identify common geometry between scan positions. Without adequate overlap (typically 20–40%), cloud-to-cloud registration becomes unstable, increasing alignment errors and reducing overall accuracy.

What is georeferencing in terrestrial laser scanning workflow?

Georeferencing links the scanned dataset to real-world coordinates. This is achieved using control points and coordinate system setup. It ensures compatibility with BIM, CAD, GIS, and engineering design platforms.