Discover how 3D scanning transforms modern industry. From prototyping to digital twins, learn five essential applications that are reshaping production, quality control, and innovation in the era of Industry 4.0.

3D Scanning as the Foundation of Modern Industry

3D scanning allows for the accurate digital replication of existing components, streamlining the product development cycle. Engineers can analyze the scanned models, perform simulations, and refine designs without relying on costly and time-consuming physical prototypes.

Design and Prototyping: From Idea to Execution

Digital Replication of Objects

3D scanning enables the creation of accurate 3D models of existing items, which is invaluable in the design process. For example, in the aerospace industry, engineers scan machine components to analyze wear or test new solutions in a virtual environment. As a result, prototyping becomes faster and more cost-effective — changes are made in the digital model instead of producing successive physical versions.

Example of Application:

In the automotive sector, 3D scanning is used to analyze the aerodynamics of car bodies. Vehicles are scanned and then tested in computer simulations, allowing for shape optimization without the need for expensive physical mock-ups.

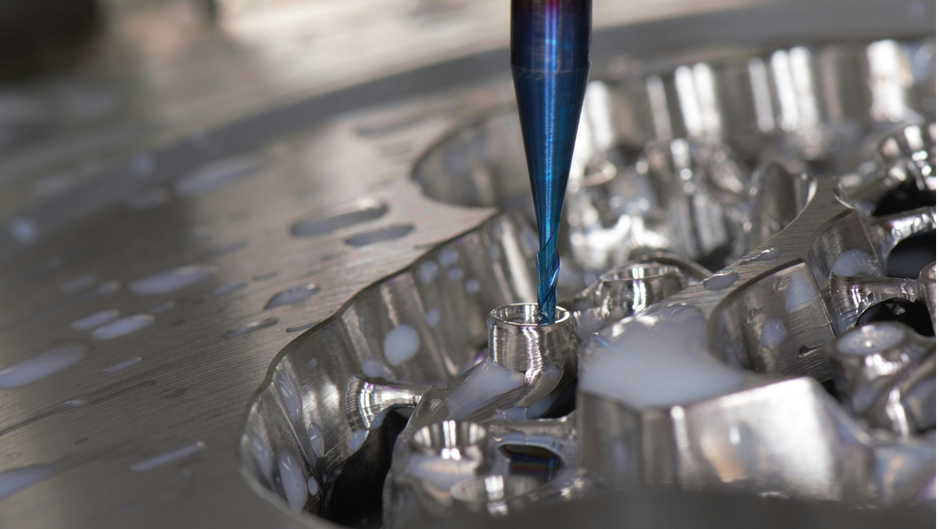

Quality Control: Microscopic Precision

Technology Supporting Zero-Error Manufacturing

Traditional quality control methods often rely on manual measurements, which are time-consuming and prone to human error. 3D scanning replaces them with automated systems that compare the digital model of a product with its ideal reference.

This solution is particularly important in the production of precision components, such as bearings or medical implants, where even a millimeter deviation can prevent proper assembly.

Case Study:

In the electronics industry, 3D scanners are used to inspect printed circuit boards (PCBs). These systems detect micro-damages in the circuitry invisible to the naked eye, ensuring device reliability.

Spare Parts Management: Digital Archiving

A Lifeline for Legacy Machinery

Many companies struggle with a lack of technical documentation for older machines or difficulty sourcing replacement parts. 3D scanning allows the creation of digital copies of such components, which can then be 3D printed or used to produce casting molds.

Industry Example:

In the energy sector, 3D scanning is used to recreate turbine components that are no longer in production. Through digitization, companies avoid downtime and maintain operational continuity.

Modern Construction and Quality Assurance: Using 3D Scanning to Detect Errors and Optimize Processes

Contemporary construction and advanced architectural projects demand not only precision but also rapid verification of compliance with design intent. 3D scanning technology allows the detection of even the smallest structural errors or project discrepancies at an early stage.

It enables quick measurement of both large structural elements and fine details — such as irregular wall joints, floor unevenness, or installation misalignments. Digital object replication eliminates human error, shortens quality control time, and allows for rapid corrections before issues lead to costly delays or dismantling.

Examples of Application:

• Interior Architecture and Furniture Design: Stationary 3D scanners accurately map spaces — especially those with unusual shapes — enabling perfect fit of cabinetry, furniture, and installations without manual measurements.

• Historical Restoration and Industrial Conservation: Precise 3D documentation of intricate architectural details enables faithful reproduction and supports renovation planning.

• Custom and Replacement Manufacturing: In the machinery industry, 3D scanning facilitates the reconstruction of spare parts for equipment lacking technical documentation — especially vital for older or custom installations.

Digital Twins and Augmented Reality: The New Face of Industry

Merging the Physical and Virtual Worlds

3D scanning plays a crucial role in the creation of digital twins — virtual replicas of physical objects, machines, or entire production lines. These allow companies to simulate manufacturing processes, analyze component wear, and plan upgrades without interfering with the real-world environment.

Practical Applications:

• Virtual Testing and Training: With VR/AR representations of machines and workspaces, employees can train without the risk of damaging equipment — ideal for safety and operations teams.

• Infrastructure Management: Digital models of production facilities support spatial planning, assembly line reorganization, and resource control.

• Remote Inspections and Predictive Maintenance: Integrating 3D scan data with IoT sensors enables failure prediction and remote monitoring of machine and building conditions.

Strategic Advantages of 3D Scanning in Industry

3D scanning is not just a supporting tool — it is a strategic asset in digital transformation. From enhancing design workflows and minimizing production errors to enabling digital twins and preserving legacy systems, its applications are central to the future of smart manufacturing.

Companies that invest in 3D scanning gain a competitive advantage through greater efficiency, flexibility, and innovation readiness. As Industry 4.0 continues to evolve, 3D scanning remains a critical enabler of intelligent, connected, and data-driven production environments.