3D Scanning and BIM for Oil Refinery Documentation

For a major oil refinery, ScanM2 provided precise 3D laser scanning and BIM documentation services to update outdated facility plans. Due to NDA obligations, we can’t share specific details, but we’re proud to have delivered a highly detailed 3D model and 2D documentation that meet the industry’s highest accuracy standards, ensuring reliable data for ongoing operations and future planning.

Project Overview: Creating a 3D Model and 2D Documentation for an Oil Refinery

ScanM2 recently completed an extensive project for an oil refinery, providing both a detailed 3D model and 2D documentation to support accurate facility management and future expansions. Due to confidentiality agreements, specific details about the refinery’s location and identity cannot be disclosed. However, we are excited to share the meticulous process, precision technology, and benefits that laser scanning brought to this complex, active oil and gas facility.

The primary goal of the project was to address outdated facility documentation, which no longer reflected the plant’s current structure and equipment layout. Over time, modifications and additions had rendered previous plans inaccurate, which posed challenges for ongoing maintenance, safety, and compliance. To meet the client’s requirements, we conducted high-resolution laser scanning with LOD 500 (Level of Detail), achieving an extremely precise, real-world representation of the refinery. This data enabled the creation of a comprehensive 3D model (RVT format) along with 2D plans that map every significant element of the facility.

Key Results Delivered to the Client

- 3D Model in RVT Format: A precise model providing complete spatial understanding of the plant.

- 2D Documentation: Detailed factory drawings and floor plans, crucial for maintenance and compliance.

- Project Timeline: The entire scanning process was completed within seven days, while the documentation and model creation took an additional month.

This level of detail and efficiency in documentation empowers the refinery with accurate data, reducing risks and aiding in informed decision-making for future changes or expansions.

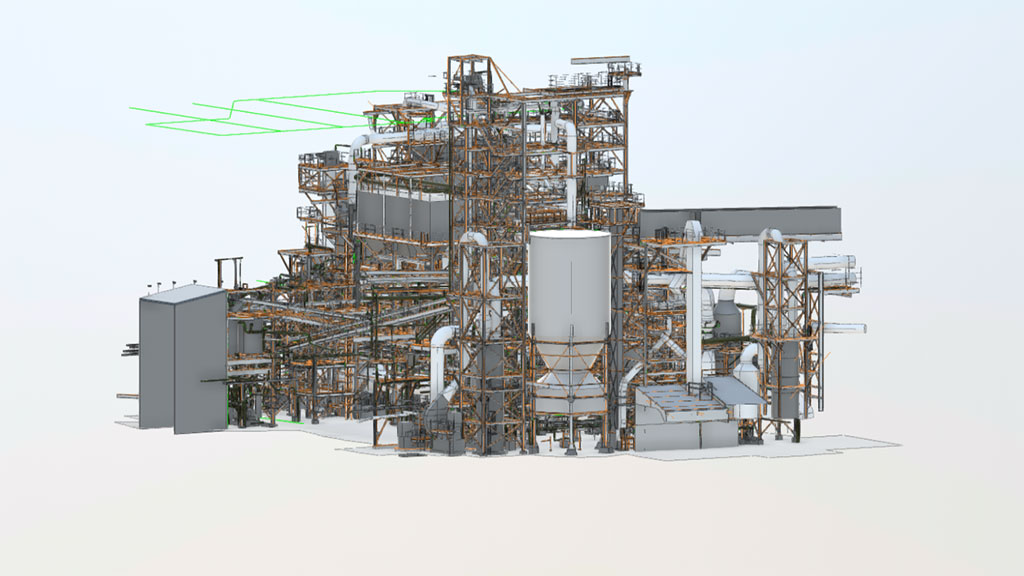

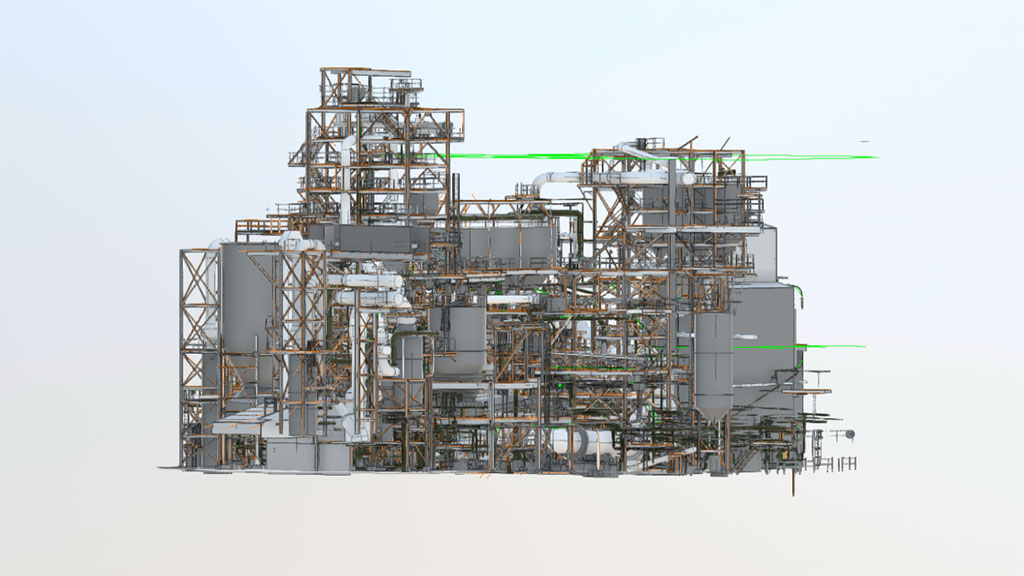

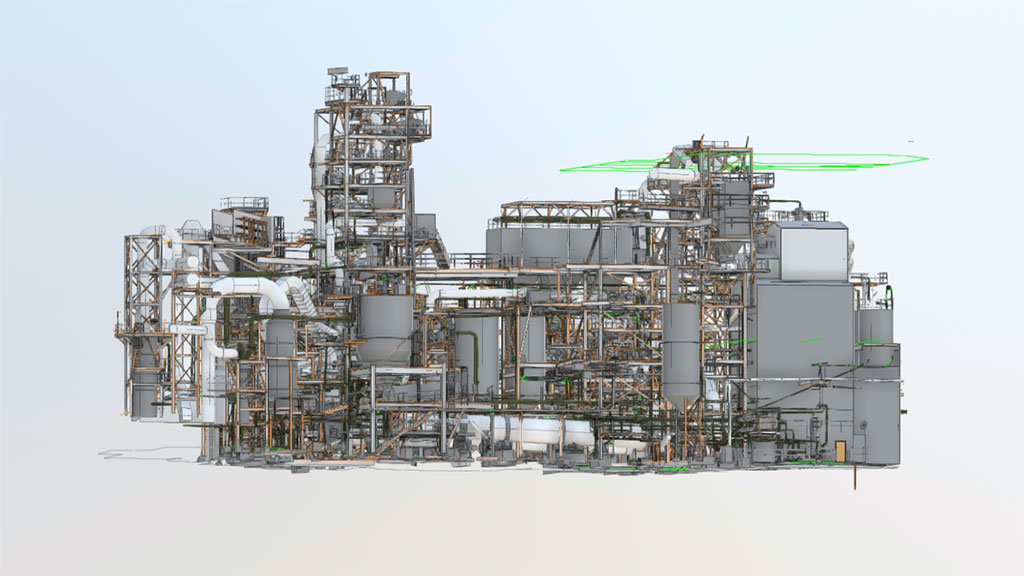

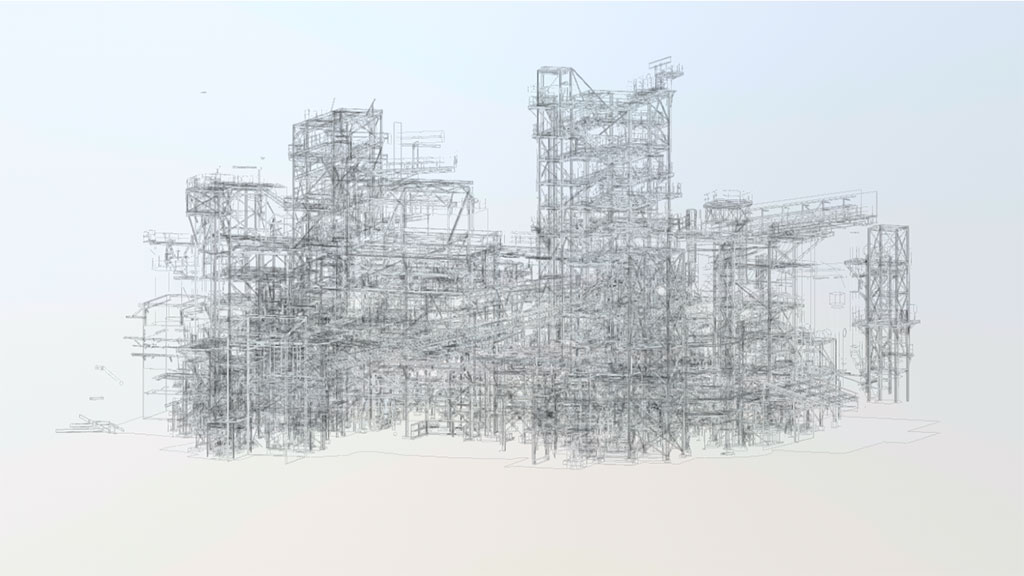

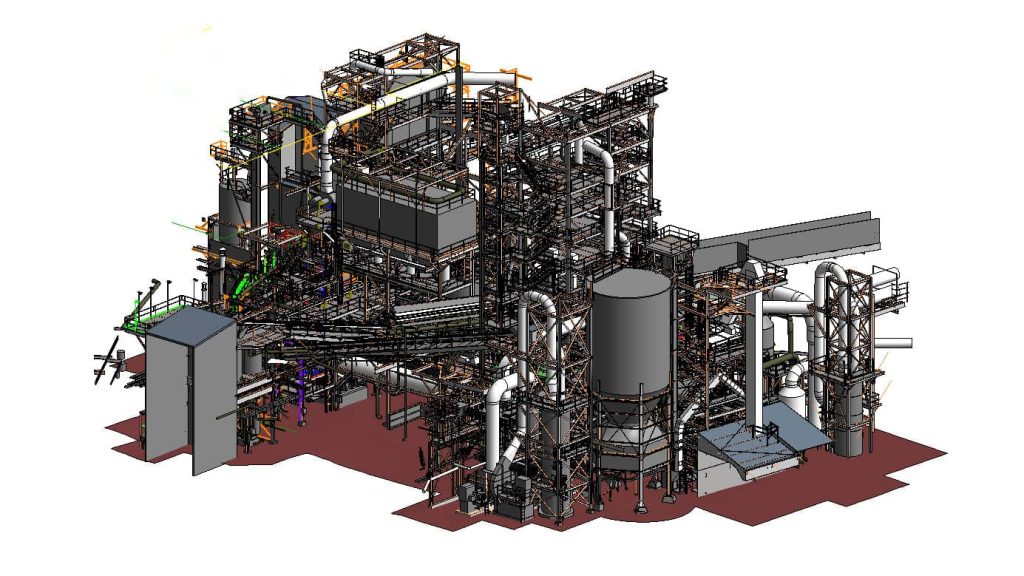

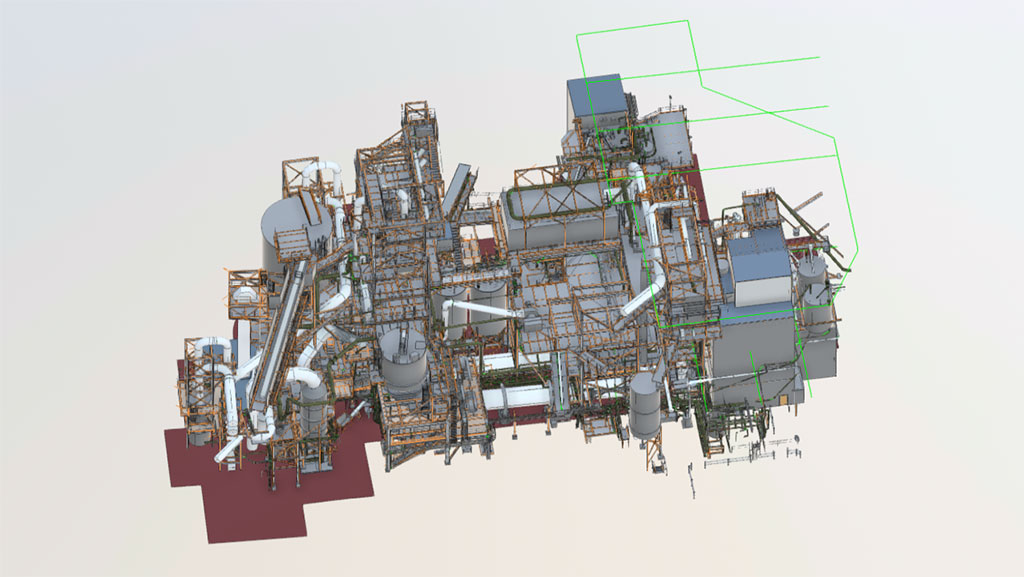

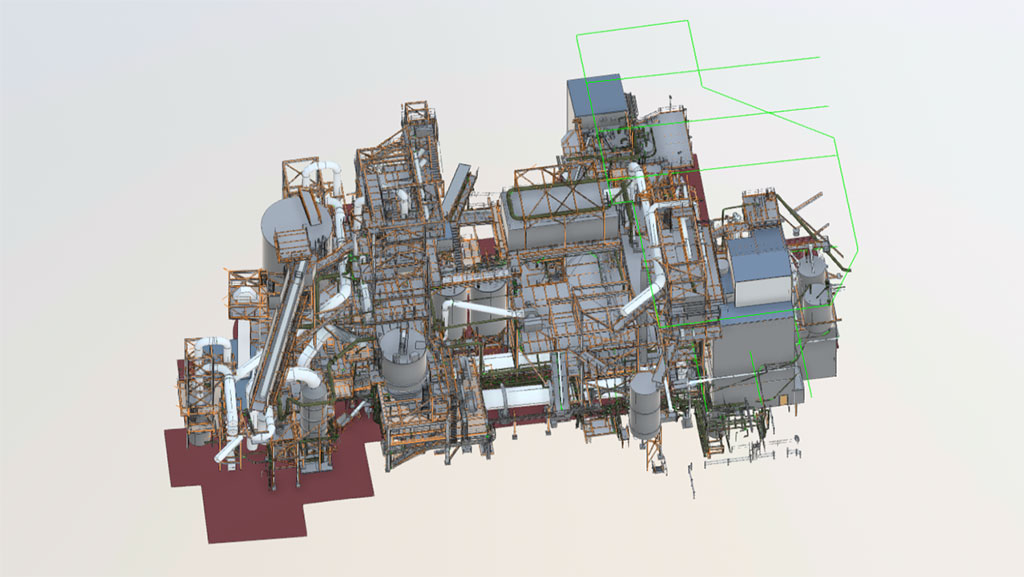

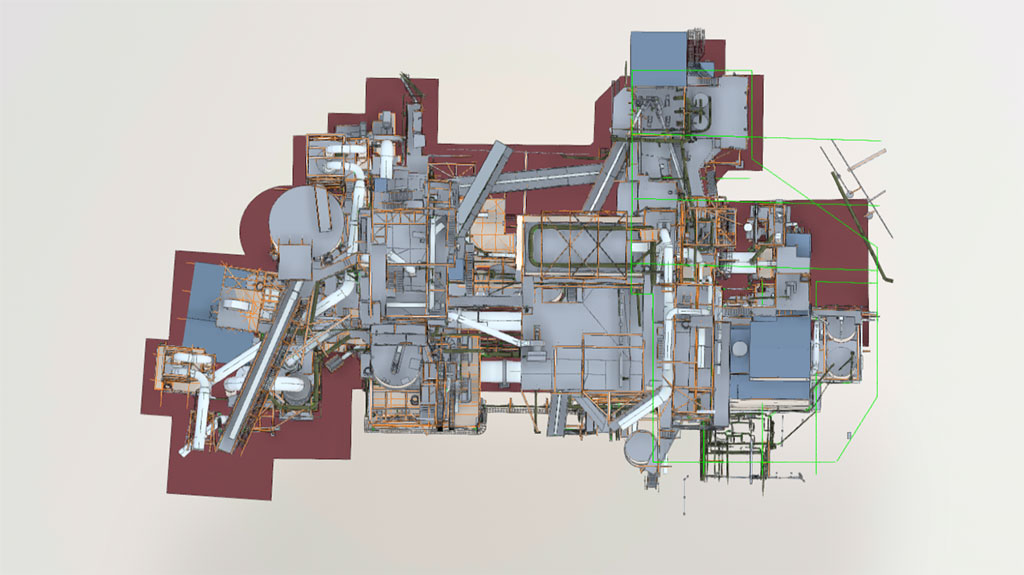

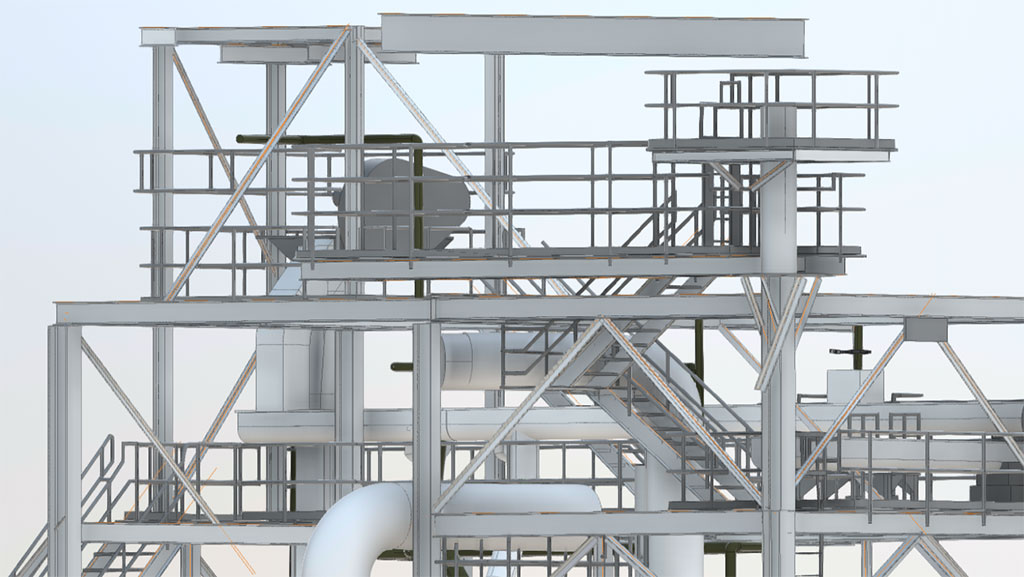

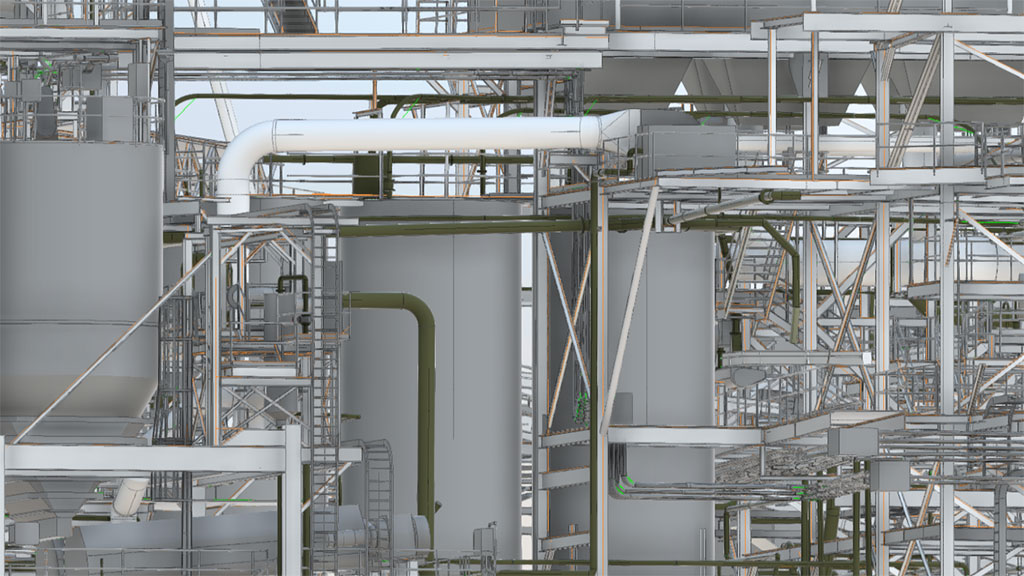

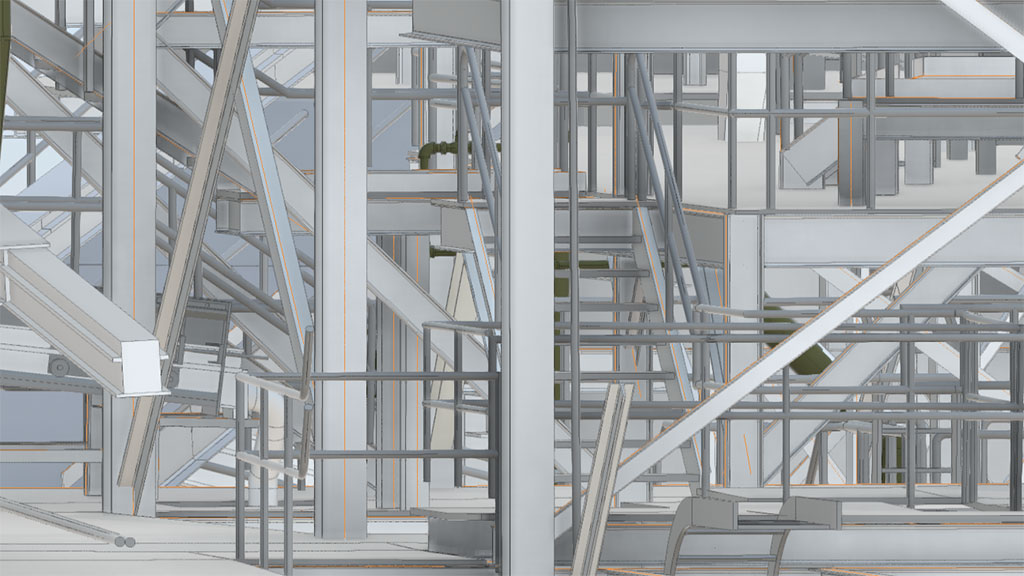

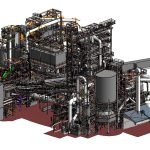

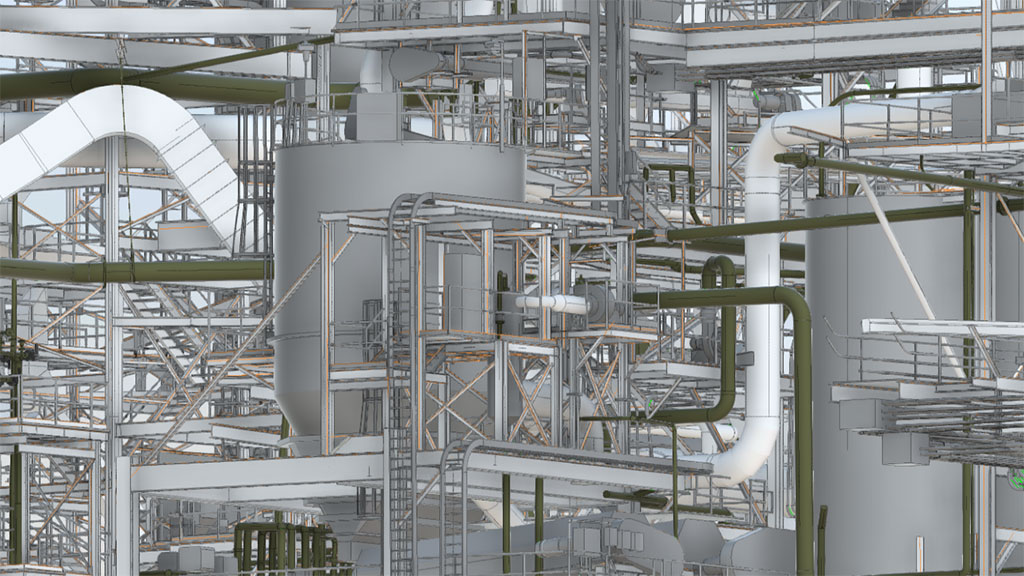

BIM Model for Oil Facility Example

Detailed Elements Scanned and Documented

During the scanning process, our team captured a wide array of structural, mechanical, and electrical components within the refinery. Here’s a comprehensive list of the elements included in the 3D model and 2D drawings:

- Structural Elements: Framing, foundations, floors, columns, walls, and roofs.

- Mechanical (MEP Drawings) and Process Equipment: Pipes, pipe fittings, ducts, mechanical equipment, and accessories.

- Safety and Access Structures: Stairs, railings, supports, and security devices.

- Electrical and Utility Components: Cable trays, conduit fittings, lighting fixtures, and electrical equipment.

- Additional Features: Topography, generic models, soffits, and analytical panels.

This comprehensive scope of detail allowed the refinery to obtain a precise model for each aspect of the facility. The accuracy of these documented elements supports the safe and efficient operation of the refinery.

The 3D Model: Visualizing the Plant with High Precision

One of the most striking outcomes of this project is the 3D model, which accurately reflects the refinery’s physical layout. Every element, from pipes and conduits to major structural components, is rendered with remarkable precision. This level of accuracy enables plant managers to navigate the model, inspect individual components, and plan updates confidently. Screenshots of the model reveal the detailed work our team invested to ensure that every component aligns with the real-world structure.

Why 3D Laser Scanning is Essential for Oil and Gas Facilities

For the oil and gas industry, reliable facility documentation plays a vital role in ensuring safe operations, planning expansions, and conducting regular maintenance. Here’s why laser scanning and BIM are invaluable for these facilities:

- Precision and Detail: 3D laser scanning captures every structural and mechanical component, essential for complex facilities with high safety standards.

- Time and Cost Efficiency: Laser scanning reduces on-site time significantly compared to manual methods, leading to cost savings.

- Safety Compliance: Up-to-date and accurate documentation ensures compliance with industry safety standards.

- Future-Ready Documentation: Accurate models facilitate easier, more precise planning for future expansions or changes.

Outdated drawings and inaccurate documentation pose risks that could lead to inefficiencies, safety hazards, and compliance issues. With ScanM2’s laser scanning services, clients gain access to current, reliable data that supports better decision-making and operational efficiency.

Our Efficient and Cost-Effective Laser Scanning Process

Many in the industry assume that 3D laser scanning is prohibitively expensive. However, ScanM2 breaks this misconception with affordable, high-quality scanning solutions. By using cutting-edge laser technology, we work faster than traditional, manual methods, delivering a precise model at a more accessible price point.

How ScanM2’s Laser Scanning Stands Out

Unlike competitors relying on handheld or manual scanning methods, we deploy advanced, automated laser systems that reduce scanning time and enhance accuracy. For the oil refinery project, this allowed us to complete the on-site scan within seven days, capturing everything with pinpoint precision. Our approach not only speeds up the scanning process but also minimizes costs for the client, making high-detail scanning feasible and affordable.

The Scanning and Documentation Workflow

To ensure the highest level of accuracy and efficiency, our team follows a structured process for every scanning project. Here’s a closer look at our workflow for the refinery documentation:

- Site Preparation: Our team visited the refinery to understand the layout, critical areas, and unique requirements.

- Laser Scanning: Over a period of seven days, our scanning team captured every inch of the facility, achieving LOD 500 precision.

- Data Processing: The raw scan data was processed to form a high-resolution point cloud.

- Modeling and Documentation: The point cloud was transformed into a 3D model in RVT format, and we prepared detailed 2D plans.

- Delivery and Client Review: We presented the finalized model and drawings to the client, ensuring that all deliverables met their expectations.

Advantages of BIM in the Oil and Gas Industry

The Building Information Modeling (BIM) approach provides vital advantages to the oil and gas sector, going beyond traditional documentation to support real-time facility management and asset tracking. By integrating accurate, spatially aware data, BIM allows refinery operators to manage assets efficiently, plan new projects with confidence, and address maintenance needs before they escalate.

Key Benefits of BIM for Oil and Gas

- Enhanced Asset Management: BIM offers a streamlined way to monitor equipment conditions, track usage, and schedule maintenance.

- Safety and Compliance: Access to up-to-date models helps operators ensure compliance with health and safety regulations.

- Efficient Project Planning: With a highly detailed digital model, expansions, retrofits, and repairs can be planned with minimal risk.

- Reduced Downtime: When incidents arise, operators can quickly identify issues within the model, reducing facility downtime.

By choosing ScanM2 for their llaser scanning and BIM needs, oil and gas clients benefit from the enhanced control, safety, and project planning that our models support.

Conclusion: Why Choose ScanM2 for Laser Scanning and BIM

ScanM2’s laser scanning and BIM solutions are designed to provide the oil and gas industry with the highest levels of accuracy, efficiency, and cost-effectiveness. Our work with this refinery highlights our commitment to delivering detailed documentation that supports both operational safety and facility expansion needs. With competitive pricing and advanced scanning technology, we make 3D laser scanning accessible, accurate, and affordable.

Ready to Transform Your Facility’s Documentation?

If you’re seeking reliable, precise, and affordable 3D laser scanning and BIM services for your oil or gas facility, ScanM2 is here to help. Our expert team will create a comprehensive model tailored to your needs, reducing costs, increasing safety, and enabling informed decision-making. Reach out to ScanM2 today to discuss your project requirements, view examples from our portfolio, and learn how our solutions can benefit your facility. Contact us now to start transforming your facility’s documentation into an invaluable asset for the future.

Services

- High-Quality Scan to BIM in Los Angeles

- Professional Scan to BIM in Illinois

- Professional Scan to BIM Services in Houston

- Professional Scan to BIM in Florida

- Professional Scan to BIM in Dallas

- Professional Scan to BIM Services in Chicago

- Professional BIM in Washington

- Professional BIM Services in Tampa

- Expert BIM Services in St Louis

- Professional BIM Services in Seattle

- BIM Services in San Francisco

- BIM Services in Portland

- Professional BIM Services in Phoenix

- Professional BIM Services in Orlando

- High-Quality BIM Services in Omaha

- BIM Services in NYC for Architects, Designers, and Builders

- BIM Services in Nashville

- Leading Minnesota BIM Services

- BIM Services in Minneapolis

- BIM Services in Milwaukee

- BIM services in Miami

- BIM Services in Massachusetts

- BIM Services in Los Angeles

- BIM Services in Las Vegas

- BIM Services in Jersey City

- Innovative BIM Services in Irvine

- BIM Services in Connecticut

- BIM Services in Illinois

- BIM Services in Florida

- BIM services in Dallas

- BIM Services in Colorado

- BIM Services in Chicago

- BIM Services in California

- BIM Services in Boston

- BIM Services in Austin

- BIM Services in Atlanta

- BIM Services in San Diego

- BIM Services in San Antonio

- BIM Services in Denver