Shop Drawings vs As-Built Drawings — Meaning, Differences, Examples & Complete Guide

The construction industry generates many different drawing types: design drawings, construction drawings, shop drawings, redlines, BIM models, and as-built drawings. Among them, shop drawings and as-built drawings are the most frequently used and the most frequently confused. Many professionals—even those with years of field experience—misunderstand what each set represents, when they are created, and how they influence the final project.

This guide explains both concepts in practical, simple language. Whether you are new to construction or want to clarify the difference between shop drawings and as-built drawings, here you will find clear definitions, examples, a detailed comparison table, and answers to common questions such as:

- What is a shop drawing?

- What is an as-built drawing?

- What are as-built drawings used for?

- What are the differences between shop drawings and as-built drawings?

- How are they created?

We also include common search variants such as “shop drawing meaning,” “as-built drawings meaning,” and similar terms —because this topic is frequently searched worldwide.

What Are Shop Drawings? (Definition, Meaning, Purpose)

A shop drawing is a highly detailed drawing prepared by contractors, manufacturers, or fabricators that shows how a component will actually be built or installed. While the architect or engineer provides design intent, shop drawings translate intent into constructible detail.

✔ Clear Definition

Shop drawing = a contractor-prepared drawing showing fabrication, assembly, and installation details before construction begins.

Shop drawings do not show how the building looks; they show how it works, how parts connect, and how they will be fabricated.

Shop Drawing Meaning

People often search for phrases like “shop drawing meaning.” The definition is straightforward:

A shop drawing explains the precise method of fabricating and installing a building component, following the design intent but providing real-world construction details.

Architects review shop drawings, but they are not the creators—they only approve them or request revisions.

Who Creates Shop Drawings?

Shop drawings are typically created by:

- Steel fabricators

- HVAC contractors

- Electrical subcontractors

- Plumbing/fire protection contractors

- Millwork and casework shops

- Precast concrete suppliers

- Window, curtain wall, and glazing vendors

- Manufacturers producing specialty items

Each trade is responsible for its own coordinated shop drawings.

Purpose of Shop Drawings

1. Translate design intent into manufacturable detail

The architect designs the idea; the contractor designs the fabrication.

2. Confirm constructibility

Shop drawings check if dimensions, tolerances, and clearances actually work.

3. Facilitate multi-trade coordination

MEP systems must avoid clashes. Shop drawings allow overlay comparison and conflict resolution.

4. Obtain approval before fabrication

Fabricators cannot proceed without architect/engineer approval.

5. Avoid installation errors

Accurate shop drawings reduce delays and rework.

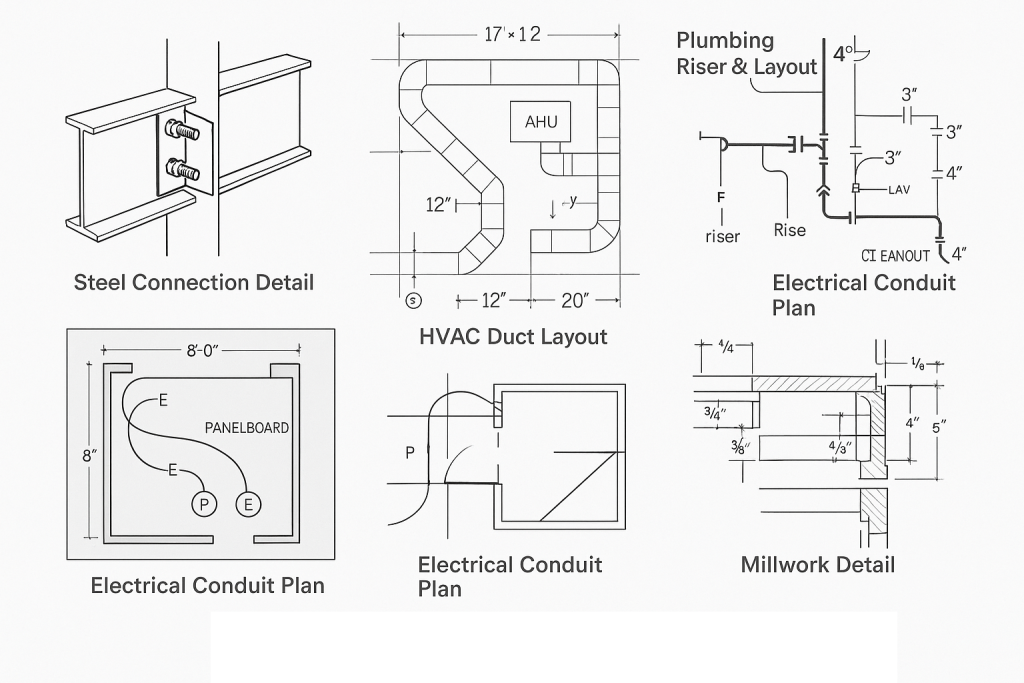

What Do Shop Drawings Include?

A complete shop drawing set includes:

- Exact dimensions

- Fabrication details

- Material specifications

- Connection and joint details

- Anchors and fasteners

- Locations relative to structure

- Routing for ducts, pipes, conduits

- Equipment mounting details

- Finish specifications

- Notes and installation instructions

- Clearances and tolerances

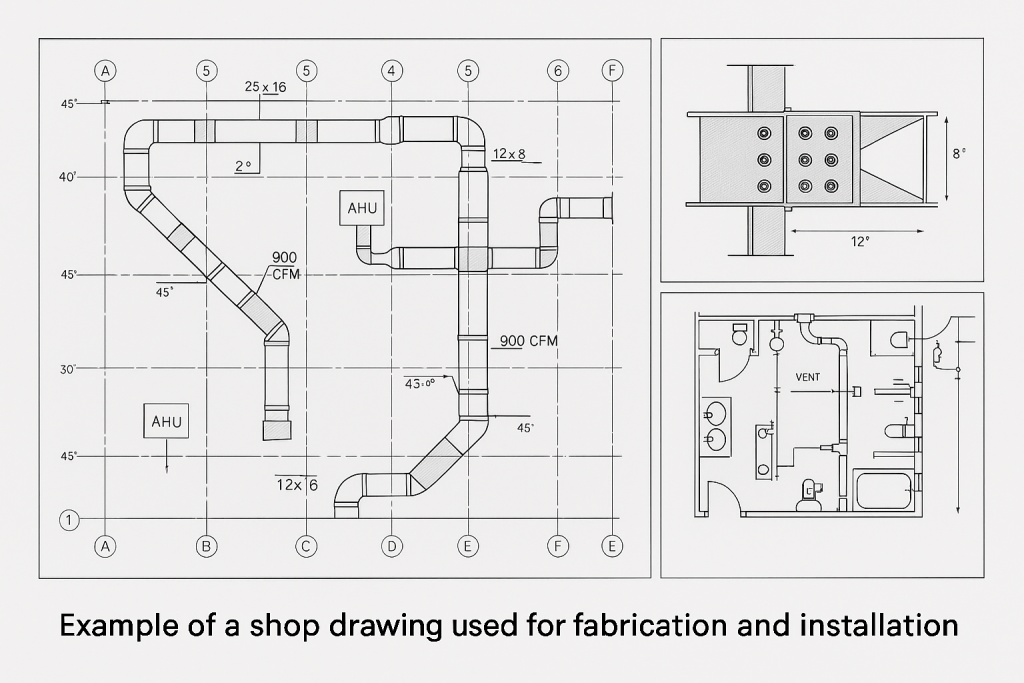

Examples of Shop Drawings

1. Steel Shop Drawings

Show welds, bolt sizes, connection plates, accurate member lengths, and erection sequencing.

2. HVAC Shop Drawings

Include duct routes, transitions, airflow requirements, equipment connections, and ceiling coordination.

3. Plumbing & Fire Protection Shop Drawings

Show pipe sizes, slopes, cleanouts, risers, sprinkler head spacing, hanger locations.

4. Electrical Shop Drawings

Include conduit paths, panelboard locations, lighting layouts, and circuiting.

5. Millwork Shop Drawings

Show joinery, finishes, edge details, hardware, and fabrication methods.

Transition

Shop drawings show how the building is intended to be assembled.

But the real world is messy—things change during construction.

This brings us to as-built drawings.

What Are As-Built Drawings? (Definition, Meaning, Purpose)

While shop drawings reflect the intended installation, as-built drawings reflect the final, real installation after construction is complete.

✔ Clear Definition

As-built drawing = a revised drawing showing the exact built condition of a structure after all field changes are incorporated.

They document every deviation from the original plan and capture what truly exists on site.

As-Built Drawing Meaning

People often search for terms like “as-built drawings meaning” or “what is as-built.”

The definition is simple:

An as-built drawing represents the actual final condition of a construction project, including all changes made in the field.

To get accurate documentation of existing conditions, many professionals rely on a dedicated As-Built Drawings service that captures every field modification and delivers precise architectural, structural, and MEP as-builts.

Why Are As-Built Drawings Important?

1. They record deviations from the design

No project is installed exactly as originally planned.

2. They provide accurate dimensions

Actual measured values replace design assumptions.

3. They support facility maintenance

Operations teams rely on as-builts to locate utilities, valves, equipment, and hidden systems.

4. They reduce risk in future renovations

Accurate information prevents destructive investigations and redesign.

5. They serve as legal documentation

Most contracts require as-built submissions at project close-out.

What Do As-Built Drawings Include?

As-built drawings reflect:

- Final wall locations

- Revised dimensions

- Exact field routing of ducts, pipes, conduits

- Structural member modifications

- Equipment relocation

- Field redlines and markups

- RFI-related changes

- Material substitutions

- Grade/elevation changes

- Underground utility adjustments

- Photos (in modern digital as-builts)

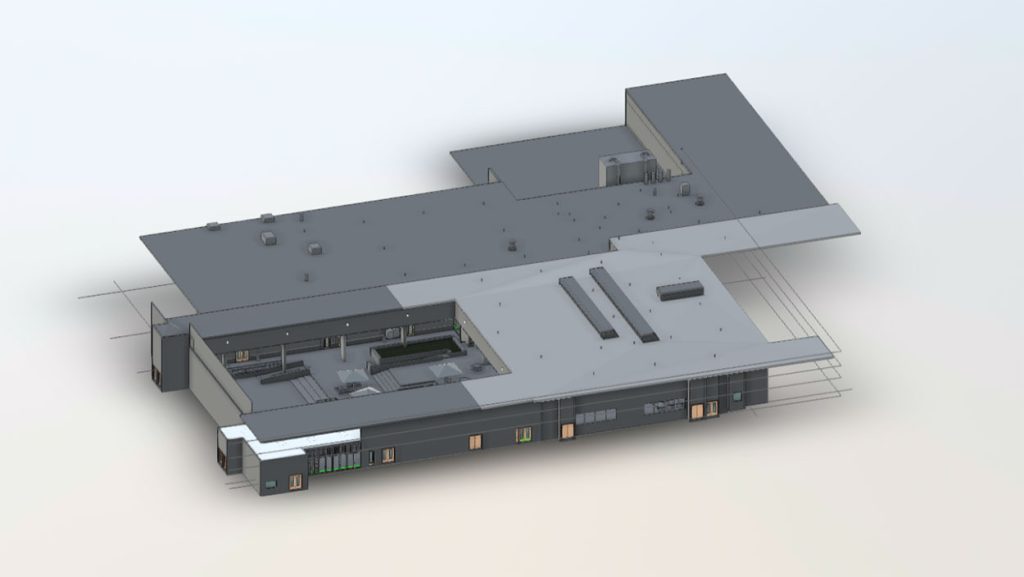

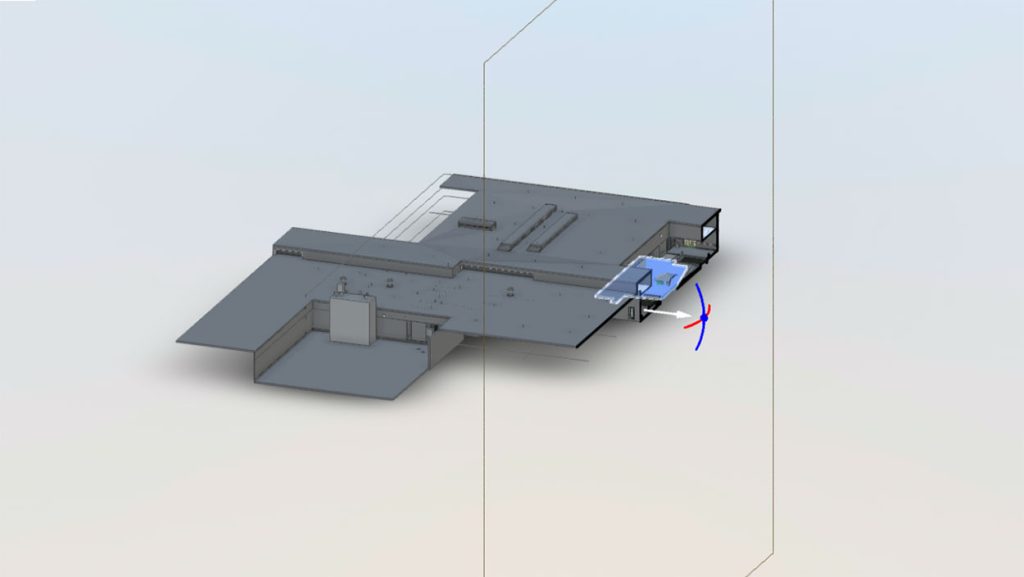

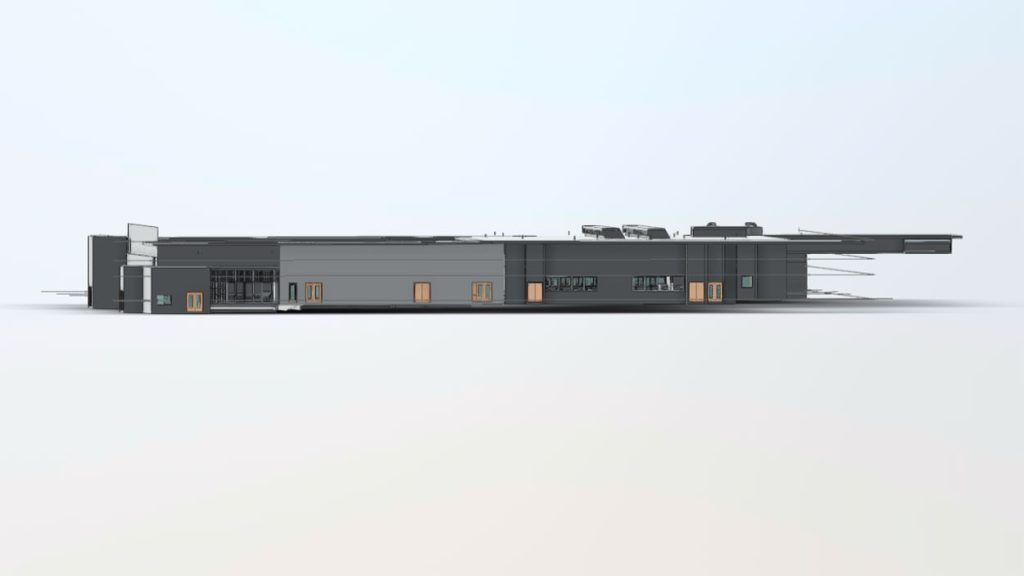

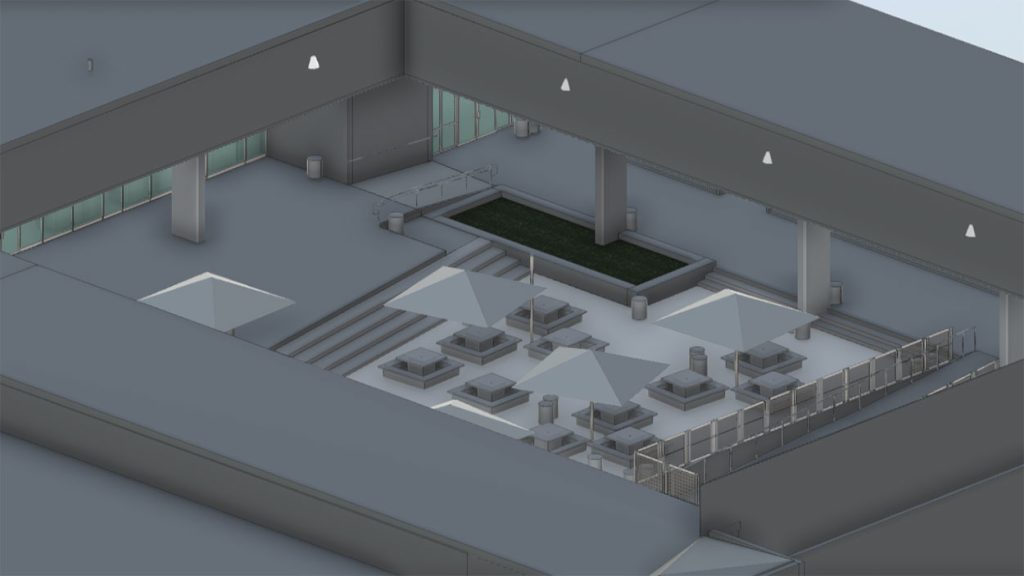

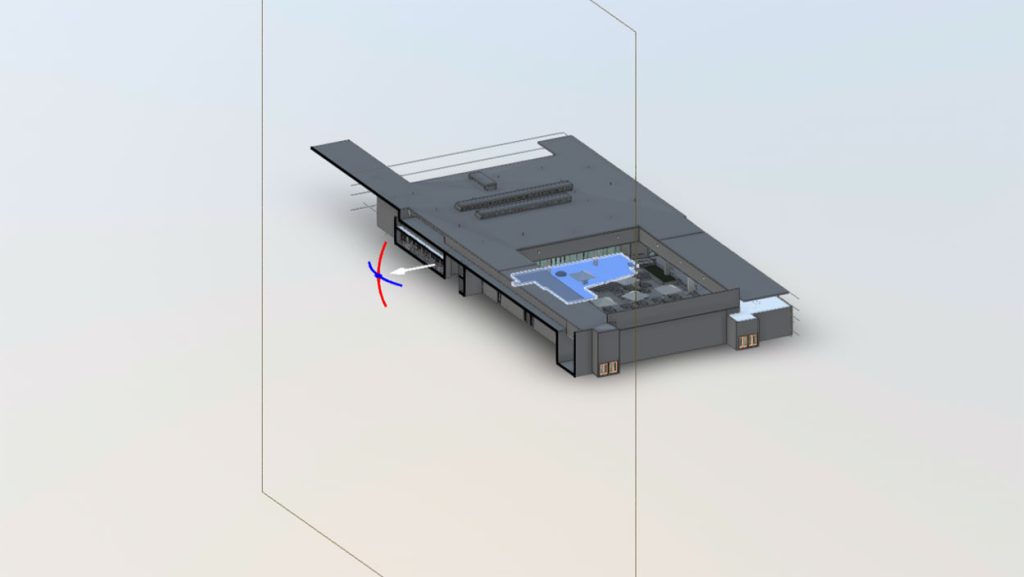

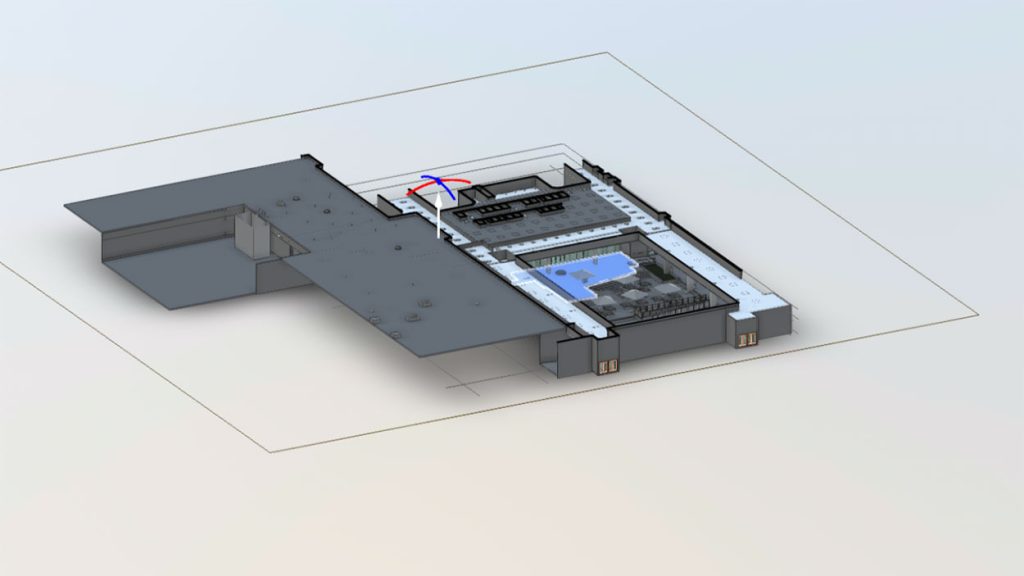

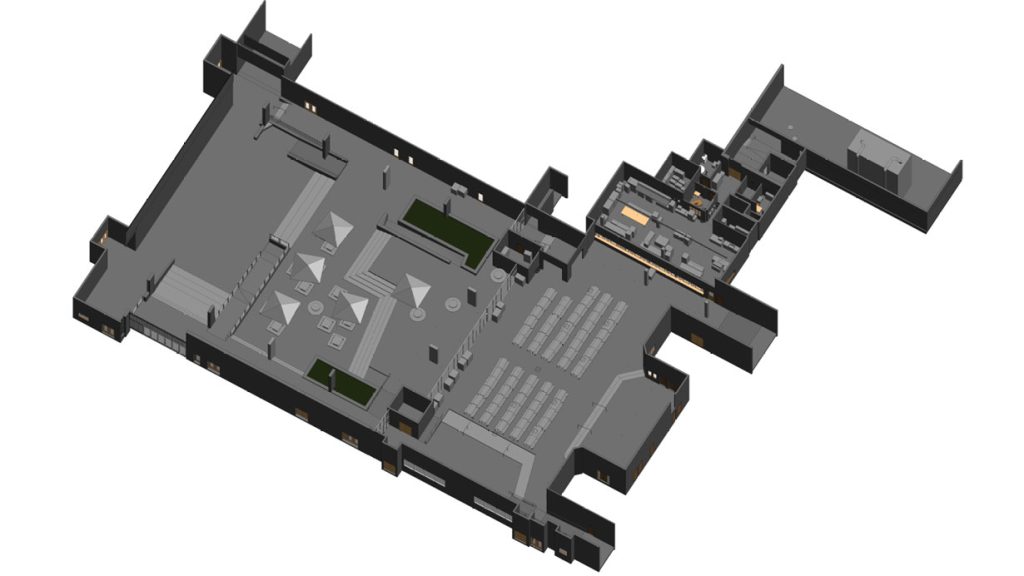

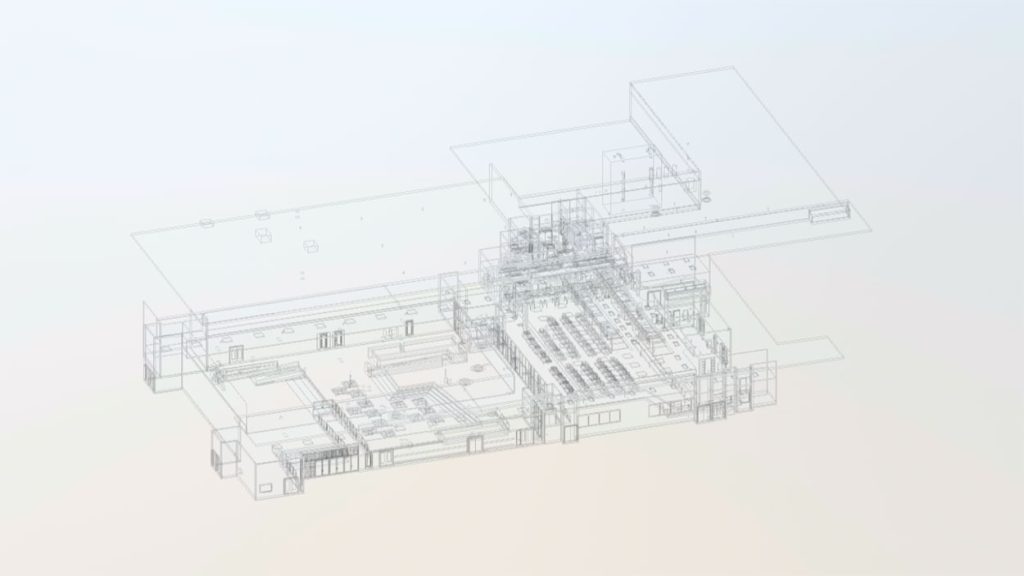

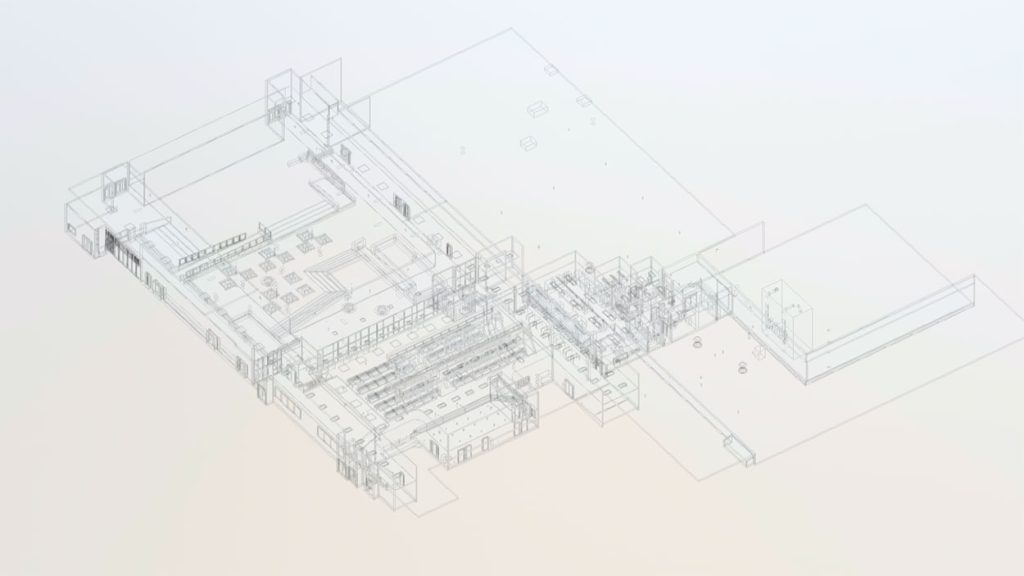

As-Built Drawings Example – Case Study of a School in Las Vegas

As-Built Documentation for a school

📁 Want to explore more real case studies?

Visit our Project Portfolio: https://scanm2.com/portfolio/

How As-Built Drawings Are Created

There are four common methods:

1. Contractor Redlines

The contractor marks changes on printed drawings.

2. Field Measurements

Surveyors measure final dimensions.

3. CAD Updates Based on Redlines

The project team updates the digital drawings with field changes.

4. 3D Laser Scanning → As-Built Modeling

The most accurate method, using point clouds for exact geometry.

SHOP DRAWINGS vs AS-BUILT DRAWINGS — FULL COMPARISON TABLE

| Category | Shop Drawings | As-Built Drawings |

|---|---|---|

| Purpose | Show how components should be fabricated and installed | Show how components were actually built |

| Created By | Contractors, fabricators, subcontractors | Contractors, field engineers, surveyors |

| Timing | Before or during fabrication | After construction |

| Accuracy Level | High detail, but based on design | Highest accuracy, based on field conditions |

| Represents | Proposed installation | Final built installation |

| Includes | Dimensions, materials, fabrication details | Revisions, deviations, actual measurements |

| Used For | Coordination, approval, fabrication | Maintenance, renovation, documentation |

| Change Source | Coordination changes | Field conditions, RFIs, unforeseen issues |

| Legal Status | Part of submittal process | Part of project close-out requirements |

| Other Names | Fabrication drawings, coordination drawings | Record drawings, as-builts |

Key Differences Explained in Detail

1. Stage of Creation

Shop drawings → before installation.

As-builts → after installation.

2. Type of Information

Shop drawings show theoretical installs.

As-builts show final verified dimensions.

3. Accuracy

As-builts must reflect exact site conditions.

4. Responsibility

Shop drawings → subcontractors.

As-builts → general contractor or field engineers.

5. Use Cases

Shop drawings → fabrication and coordination.

As-builts → maintenance, operations, renovations, legal documentation.

Common Mistakes with Shop & As-Built Drawings

❌ Using shop drawings as as-builts

Shop drawings are not accurate after field changes.

❌ Failing to document deviations

Contractors often skip updating changes unless required.

❌ Poor coordination

Uncoordinated shop drawings can lead to clashes.

❌ Missing information

Critical details like elevations, clearances, depths, or hidden utilities are often not captured.

How BIM Improves Shop Drawings and As-Builts

1. Clash Detection

BIM tools like Revit and Navisworks identify conflicts early.

2. Multi-Trade Coordination

HVAC, plumbing, electrical, and structural trades work in a unified model.

3. Faster Revisions

Changes update across the entire model.

4. Laser Scanning → BIM As-Builts

Point clouds capture exact field conditions with millimeter accuracy.

5. Digital Twins

As-builts can evolve into full digital facility models.

FAQ

What is a shop drawing?

A detailed drawing that explains how a component will be fabricated and installed.

What is an as-built drawing?

A revised drawing showing the actual built condition after construction.

What are as-built drawings used for?

Maintenance, operations, renovations, and documentation.

Shop drawing vs as-built — what’s the difference?

Shop = proposed installation.

As-built = final installation.

Who prepares shop drawings and as-built drawings?

Shop drawings are usually prepared by contractors, fabricators, or manufacturers. As-built drawings are typically created by field engineers, surveyors, or BIM teams after construction changes are documented.

Are shop drawings part of construction documents?

Yes. Shop drawings are considered part of construction documentation, supplementing architectural and engineering plans by showing how components will actually be fabricated and installed.

Why are as-built drawings important for future renovations?

As-built drawings provide accurate information about the final built condition, including hidden elements like MEP routing, structural changes, and deviations from design. This makes renovation, maintenance, and facility management safer and more efficient.

Conclusion

Shop drawings and as-built drawings serve different but equally essential purposes in construction. Shop drawings help ensure that components are fabricated and installed correctly, while as-built drawings capture the final built condition. Understanding both helps avoid errors, improve coordination, ensure safety, support maintenance, and provide accurate documentation for future work.

Whether you’re a new engineer, contractor, or project manager—or simply searching for terms like “shop drawing meaning,” “as built drawings,” or “what is as-built”—this guide provides the complete clarity you need.