BIM Modeling and As-Built Documentation for a Pharmaceutical Facility

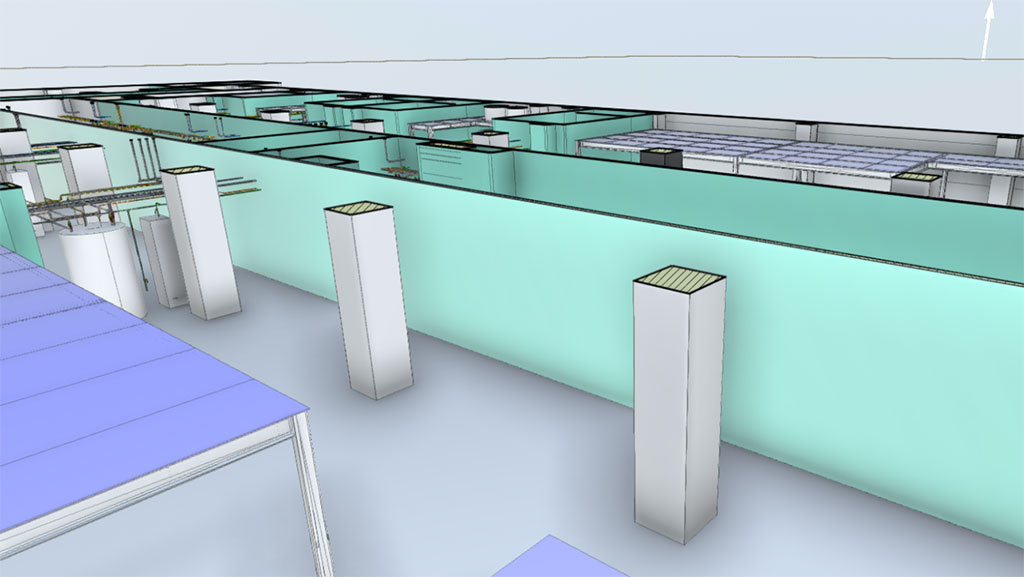

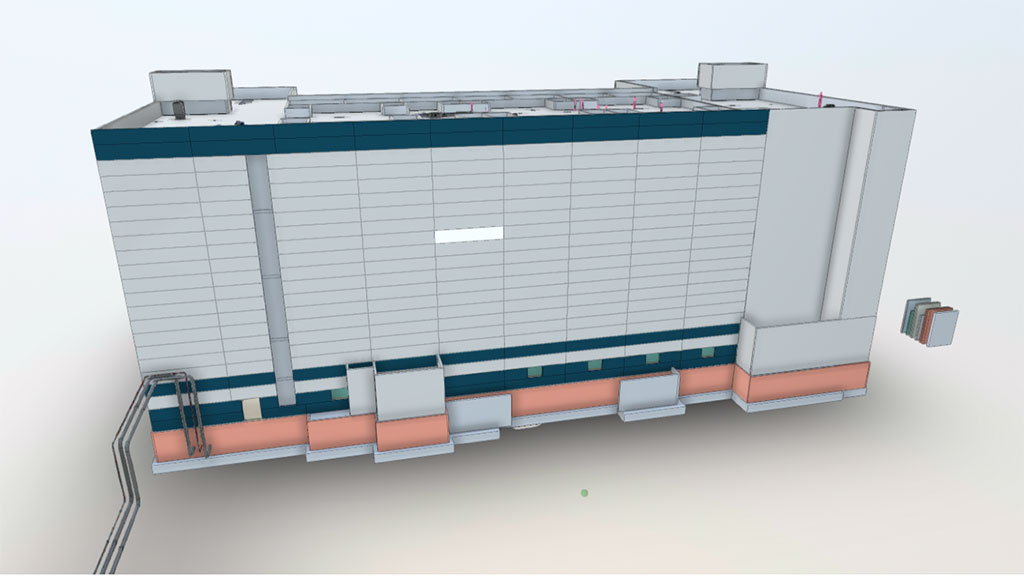

In a recent project for a confidential client in the pharmaceutical industry, our team at ScanM2 successfully completed a comprehensive 3D laser scanning and BIM modeling process to support the plant’s upcoming renovations. Due to a non-disclosure agreement, we cannot reveal the plant’s name or location, but we can share the meticulous steps and technologies used to create high-quality as-built documentation. This project included advanced LOD 450 scanning, delivering a precision-focused 3D model and CAD drawings essential for FDA-compliant facility management and future reconstruction efforts.

Due to a non-disclosure agreement, we are not permitted to disclose the name or location of the plant.

Pharmaceutical Plant 3D Scanning: Why Precision Matters

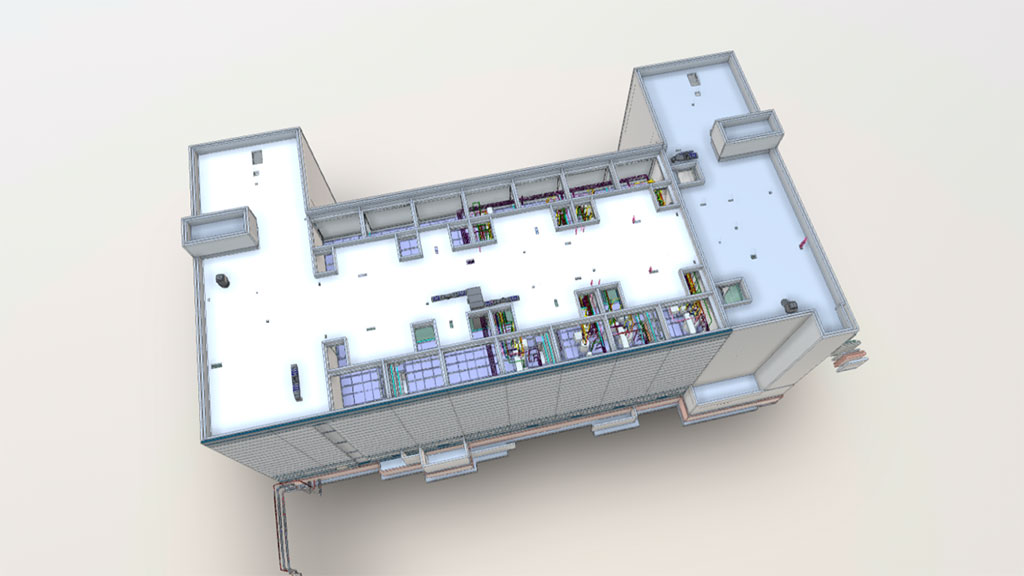

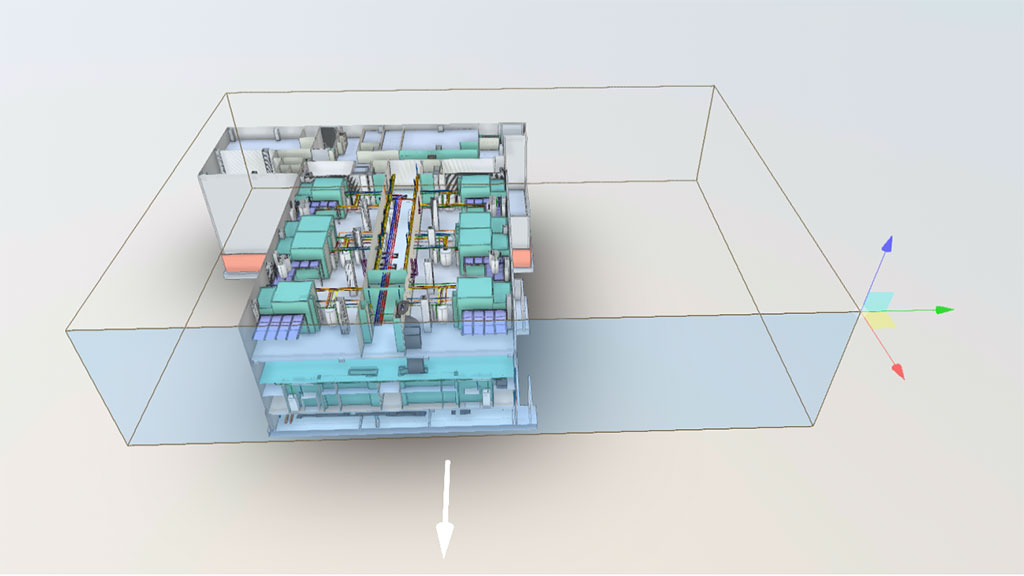

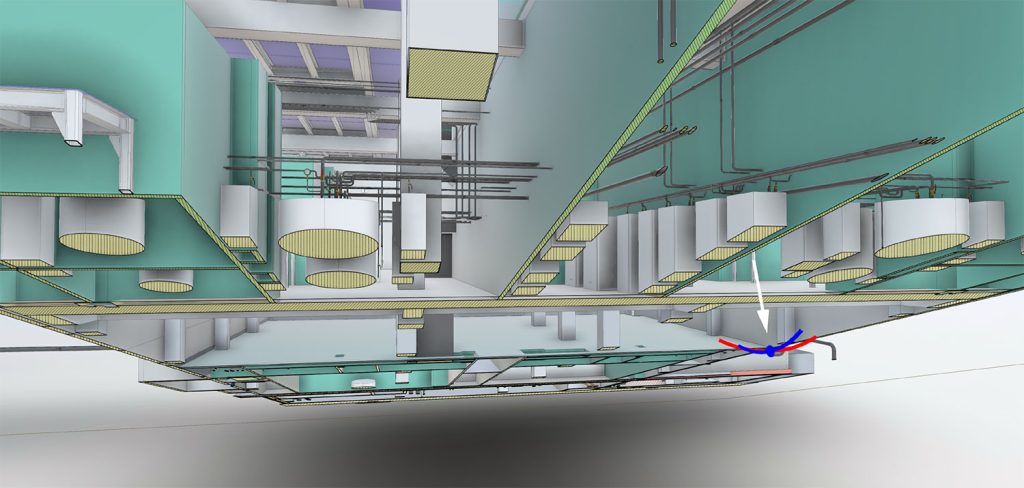

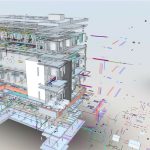

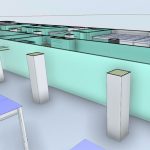

3D scanning for pharmaceutical facilities must meet extremely high standards. Unlike traditional plants, pharmaceutical facilities require extensive detail to accommodate complex MEP (Mechanical, Electrical, and Plumbing) systems, structural columns, cleanroom standards, and FDA compliance. To meet these unique demands, we employed LOD 450 laser scanning technology, capturing every essential structural and architectural detail with minimal margin for error.

With this high-precision approach, we documented the following key elements:

- Interior and Exterior Walls

- Doors and Windows

- Ceilings and Staircases

- Structural Columns and Slabs

- Safety Railings and Barriers

- Comprehensive MEP Systems

This level of detail ensures that every element critical to operational and compliance standards is accurately mapped, enabling a seamless transition to the 3D BIM model.

Our BIM Model for Oil Pharmaceutical

The 3-Day Scanning Process for Maximum Efficiency

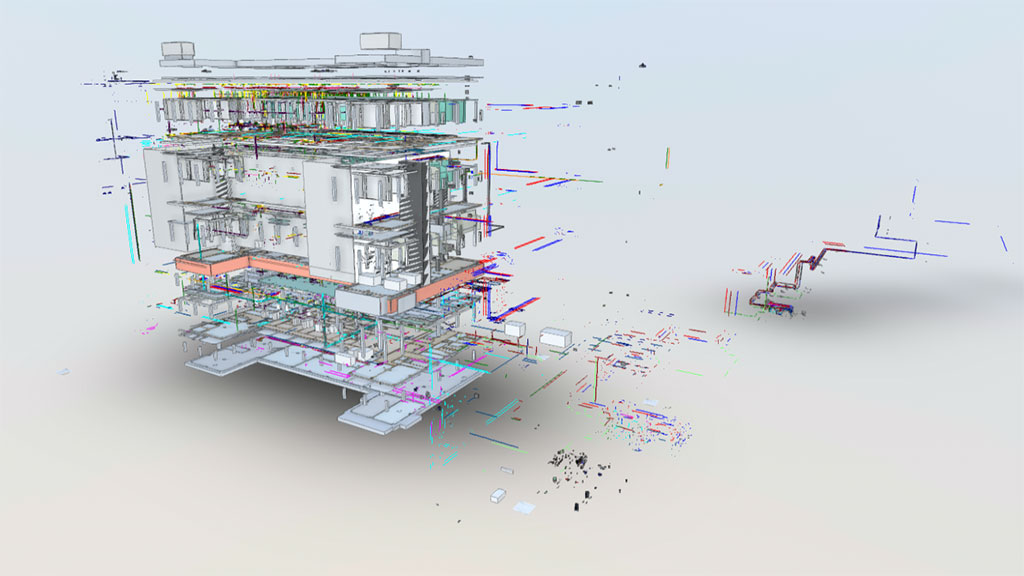

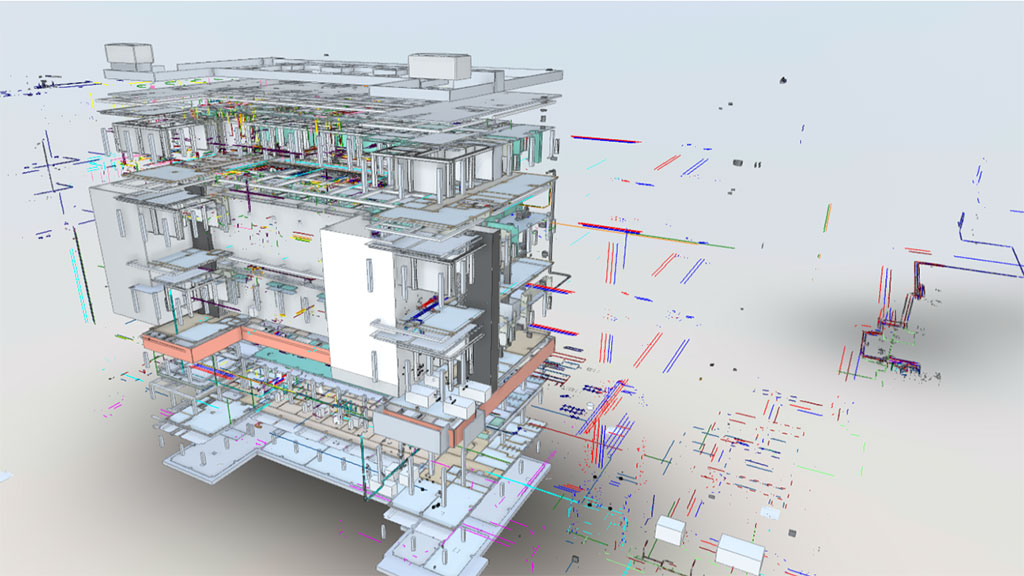

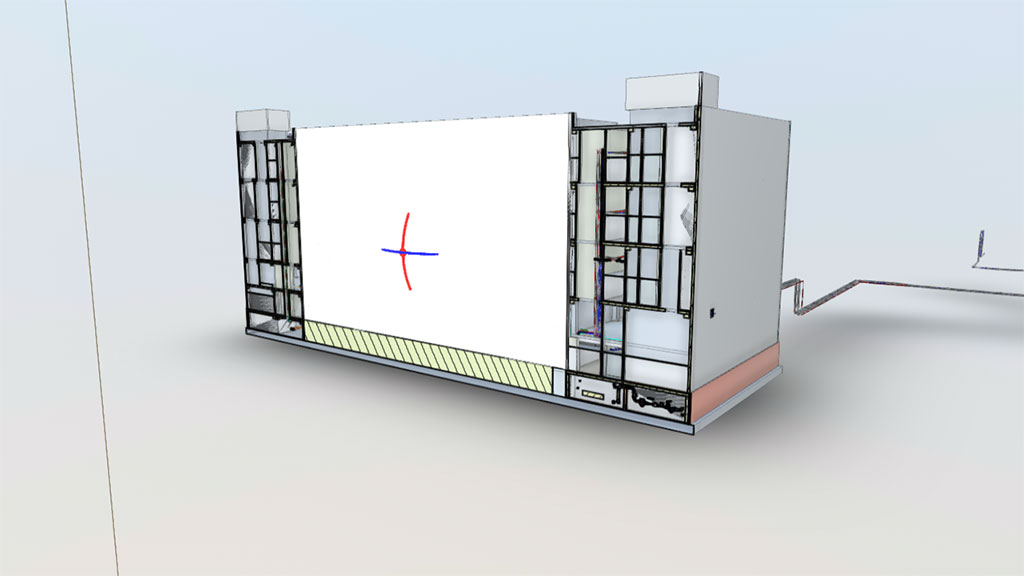

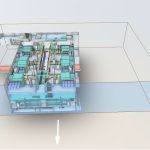

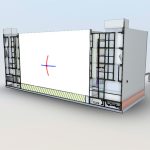

Efficiency is crucial, especially in industries where downtime can have significant financial impacts. The ScanM2 team completed the entire scanning process within three days using cutting-edge equipment and expertise. This rapid turnaround allowed us to capture millions of data points, creating a highly accurate point cloud representation of the facility. The data was then converted into a 3D model, ready for Archicad integration and easy transfer to CAD applications.

Comprehensive As-Built Documentation in Just Two Weeks

Beyond 3D scanning, we also delivered detailed 2D documentation within two weeks of the scan. This documentation included floor plans, elevations, and CAD drawings that serve as the foundation for the pharmaceutical plant’s planned renovation. Since the previous as-built documents were outdated, this new data is now a critical resource, accurately reflecting the current state of the plant for effective project planning and execution.

BIM Modeling for Pharmaceutical Facilities: Key Advantages

Building Information Modeling (BIM) has revolutionized how pharmaceutical plants are managed and upgraded. For this project, BIM modeling provided the following advantages:

- Enhanced Facility Management: Our BIM model offers a digital twin of the plant, allowing facility managers to track assets, plan maintenance, and assess compliance risks in a digital environment.

- Detailed Visualization: The 3D model improves visualization for all stakeholders, from architects to construction teams, ensuring everyone has access to accurate, up-to-date information.

- FDA Compliance: Pharmaceutical plants are subject to stringent FDA regulations, which require precise data on facility layout and systems. Our BIM model helps clients achieve and maintain FDA compliance by ensuring all structural and MEP systems are accurately documented.

Affordable Laser Scanning Solutions: Busting the Cost Myth

A common misconception about laser scanning is that it is prohibitively expensive. At ScanM2, we’re proud to offer competitive pricing that makes high-quality scanning accessible to businesses of all sizes. Traditional manual scanning methods, which are often more expensive and less precise, can’t match the efficiency or accuracy of our laser scanning services. By leveraging advanced scanning technology, we deliver superior detail at a fraction of the cost, making us an ideal partner for pharmaceutical companies looking to invest in accurate, affordable 3D scanning and BIM modeling.

What Makes ScanM2 the Ideal Choice?

Our clients trust us for industrial plant BIM services and 3D scanning solutions because we prioritize accuracy, speed, and affordability. In the pharmaceutical industry, where facility layout and equipment placement must meet rigorous standards, our commitment to quality ensures that clients receive detailed, reliable models and documentation tailored to their unique needs.

How This Documentation Supports FDA Compliance and Facility Upgrades

Our as-built services for pharmaceutical plants provide clients with the data they need to maintain strict FDA compliance while planning facility upgrades. From cleanroom facilities to MEP systems, the as-built documentation offers a clear picture of current assets and layout, allowing for informed decisions and accurate planning.

Key Benefits of Our Pharmaceutical Plant BIM Services

- Enhanced Planning: With a 3D model in Archicad, planning upgrades and renovations becomes a streamlined process.

- Cost Savings: By reducing the need for manual surveying and providing precise data upfront, our services lower the costs associated with inaccurate documentation.

- Reduced Downtime: With a swift scanning process and fast documentation delivery, clients experience minimal disruption to operations.

Leveraging Digital Twins for Ongoing Facility Management

Digital twin technology enables pharmaceutical plants to maintain a real-time digital replica of their facility. This model can be updated as renovations and new installations occur, creating a living document that evolves with the plant. Facility managers can leverage this tool for ongoing inspections, compliance checks, and maintenance tracking, making it easier to meet regulatory requirements.

Frequently Asked Questions

How long does 3D scanning for pharmaceutical plants take?

Our team completed the entire scanning process for this plant in just three days, thanks to our efficient workflows and advanced technology.

What is included in the as-built documentation for a pharmaceutical facility?

The documentation includes 3D models, point clouds, and 2D drawings covering walls, doors, windows, MEP systems, and more, tailored to the specific needs of pharmaceutical plants.

Is 3D scanning affordable for smaller pharmaceutical facilities?

Yes, at ScanM2, we offer competitive rates that make high-quality 3D scanning and BIM modeling accessible even to smaller pharmaceutical companies.

Why is BIM modeling important for pharmaceutical plants?

BIM modeling enhances visualization, aids in facility management, supports FDA compliance, and simplifies planning for renovations and upgrades.

How does 3D scanning support FDA compliance?

3D scanning provides highly accurate data on facility layout and systems, essential for meeting stringent FDA requirements in pharmaceutical facilities.

Can 3D scanning be used for cleanroom facilities?

Absolutely. Our scanning technology captures the intricate details needed for cleanroom areas, ensuring all compliance standards are met.

By choosing ScanM2 for your pharmaceutical plant’s 3D scanning and BIM modeling needs, you’re opting for unmatched accuracy, affordability, and efficiency, ensuring that your facility’s data is as reliable as it is detailed.

Services

- High-Quality Scan to BIM in Los Angeles

- Professional Scan to BIM in Illinois

- Professional Scan to BIM Services in Houston

- Professional Scan to BIM in Florida

- Professional Scan to BIM in Dallas

- Professional Scan to BIM Services in Chicago

- Professional BIM in Washington

- Professional BIM Services in Tampa

- Expert BIM Services in St Louis

- Professional BIM Services in Seattle

- BIM Services in San Francisco

- BIM Services in Portland

- Professional BIM Services in Phoenix

- Professional BIM Services in Orlando

- High-Quality BIM Services in Omaha

- BIM Services in NYC for Architects, Designers, and Builders

- BIM Services in Nashville

- Leading Minnesota BIM Services

- BIM Services in Minneapolis

- BIM Services in Milwaukee

- BIM services in Miami

- BIM Services in Massachusetts

- BIM Services in Los Angeles

- BIM Services in Las Vegas

- BIM Services in Jersey City

- Innovative BIM Services in Irvine

- BIM Services in Connecticut

- BIM Services in Illinois

- BIM Services in Florida

- BIM services in Dallas

- BIM Services in Colorado

- BIM Services in Chicago

- BIM Services in California

- BIM Services in Boston

- BIM Services in Austin

- BIM Services in Atlanta

- BIM Services in San Diego

- BIM Services in San Antonio

- BIM Services in Denver