Choosing the right partner for your project starts with understanding how to choose a 3D scanning company that meets your technical, scheduling, and documentation needs. Whether you are comparing laser scanning companies for a renovation, retrofit, or new construction project, selecting a qualified provider ensures accurate point cloud data, reliable as built documentation, and a smooth scan to BIM workflow. In a complex construction environment like New York City, making the right decision at this stage can directly impact project timelines, costs, and coordination efficiency.

If you’re researching how to choose a 3D scanning company, you’re likely already at the decision stage. In a competitive construction environment like New York, selecting the wrong provider can lead to inaccurate measurements, redesign costs, scheduling delays, and coordination issues.

Professional reality capture services provide highly detailed point cloud data used for:

- Precise site documentation

- Reliable as built documentation

- Accurate scan to BIM workflow

- Complete construction documentation

When hiring a laser scanning company, you’re not just purchasing a scan — you’re investing in project certainty. That’s why understanding what to look for in a laser scanning company is critical for architects, engineers, developers, and general contractors.

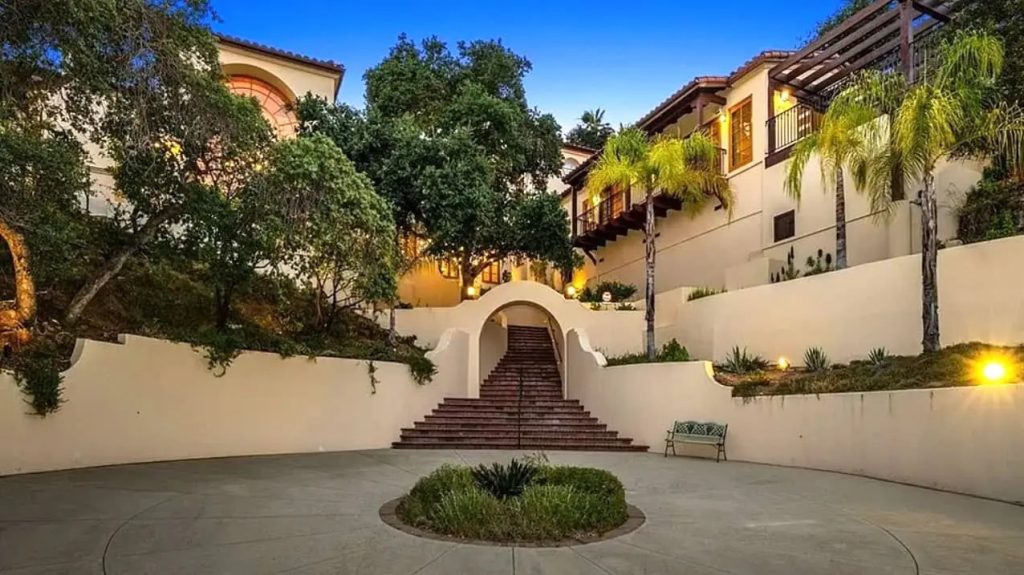

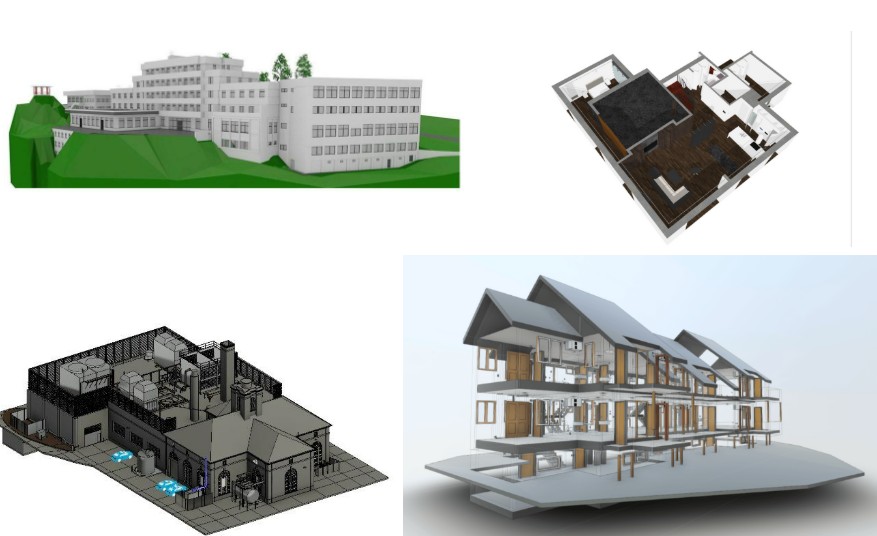

Experience in Commercial Building Scanning Projects in NYC

Experience matters more than marketing claims. A provider specializing in residential scanning may not be qualified for complex commercial projects such as:

- High-rise office buildings

- Historic renovations

- Hospitals and educational facilities

- Large-scale MEP retrofits

When comparing laser scanning companies, ask:

- Have they completed commercial architectural scanning, structural scanning, and MEP scanning projects?

- Do they understand NYC building codes and site access logistics?

- Can they handle tight schedules and occupied buildings?

A laser scanning company in New York must understand vertical construction challenges, restricted access hours, union environments, and coordination with multiple trades.

Accuracy Requirements for Laser Scanning in New York Construction

Not all scanning providers deliver the same precision. Accuracy requirements depend on project type:

| Project Type | Recommended Accuracy | Why It Matters |

| Renovation / Interior Fit-Out | ±2–3 mm | Prevents clash issues |

| Structural Modifications | ±2 mm | Ensures load-bearing accuracy |

| MEP Coordination | ±2–3 mm | Reduces rework in tight spaces |

| Façade Restoration | ±3–5 mm | Supports detailing and fabrication |

When choosing a laser scanning provider, confirm:

- Scanner calibration standards

- Registration methodology

- QA/QC process

- Verification procedures

The best 3D scanning company will clearly define tolerances before mobilization.

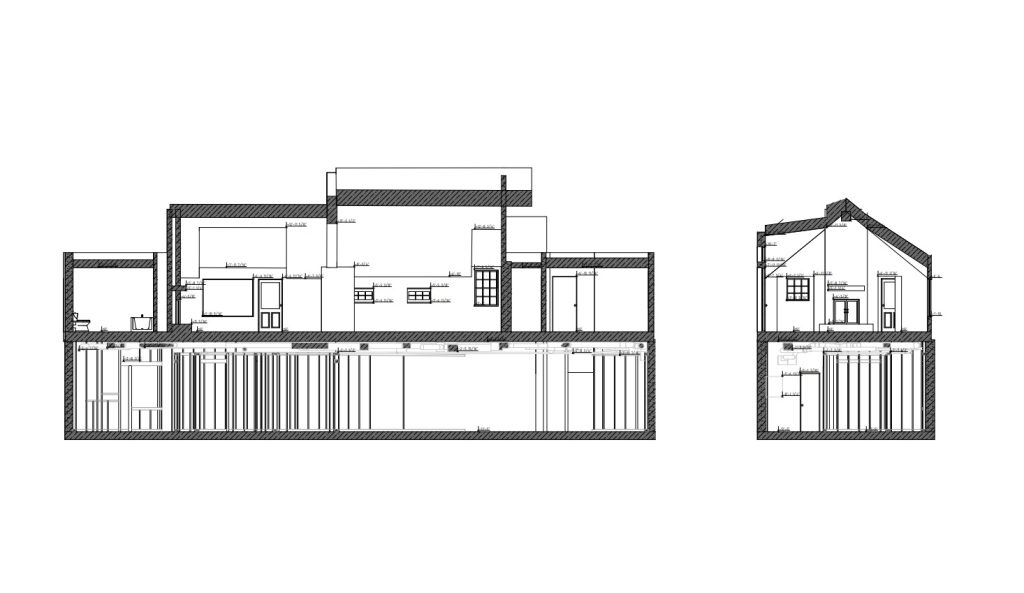

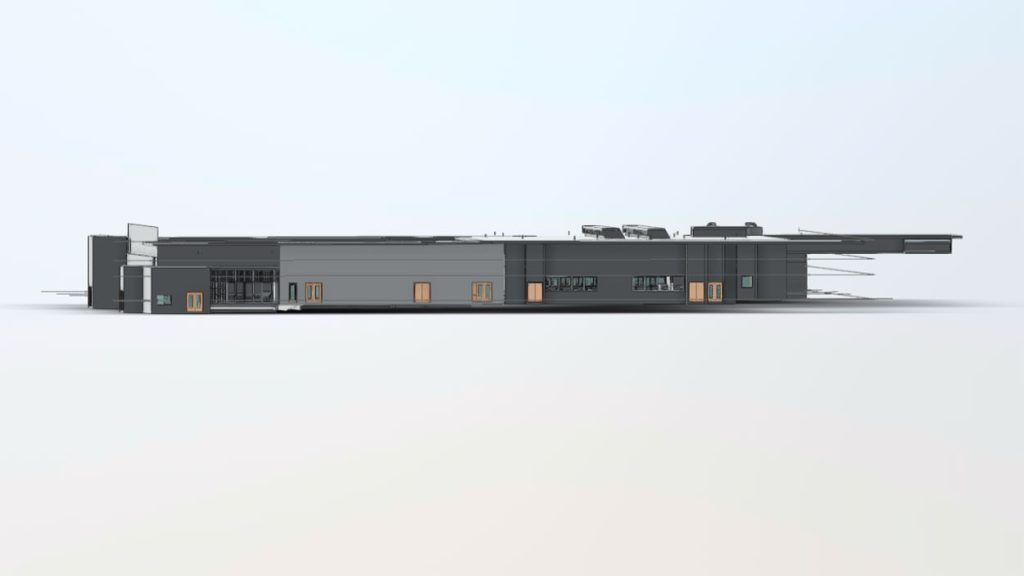

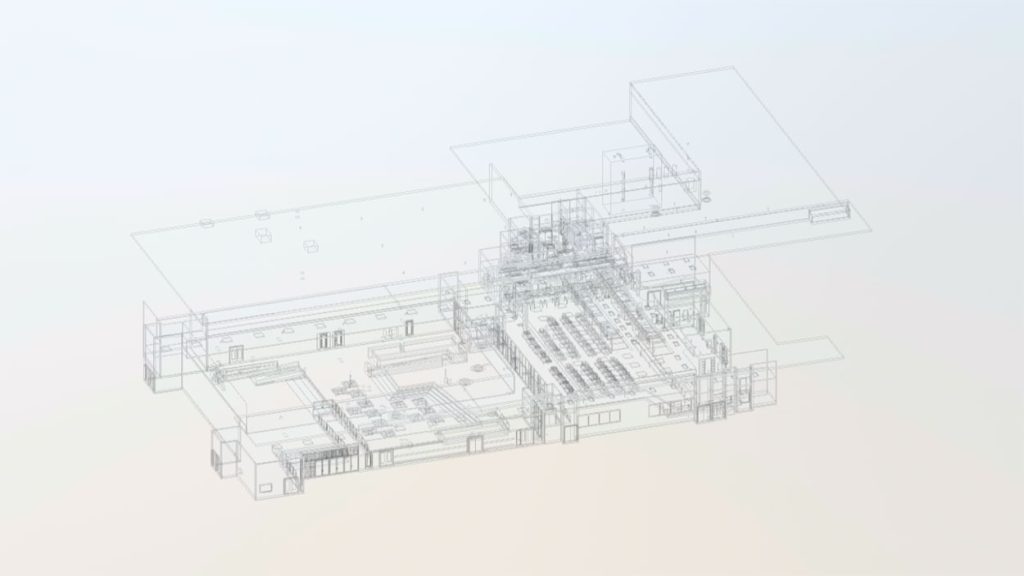

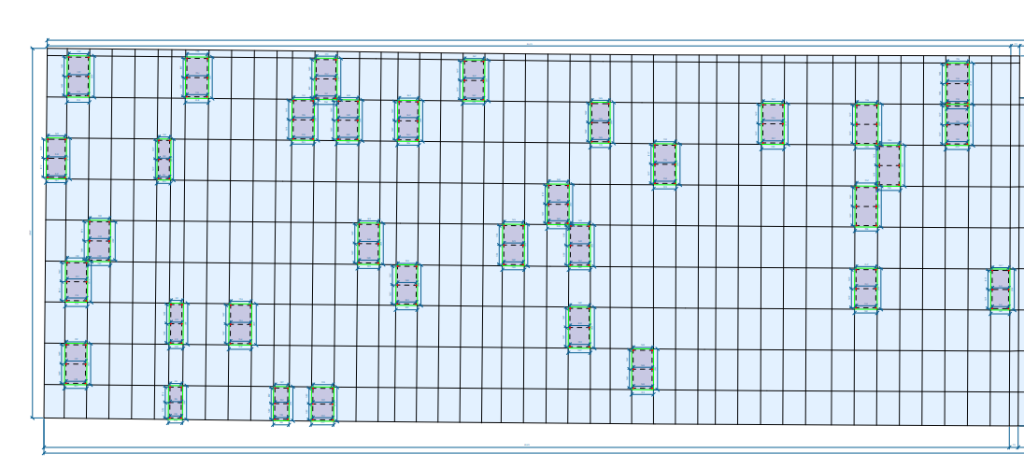

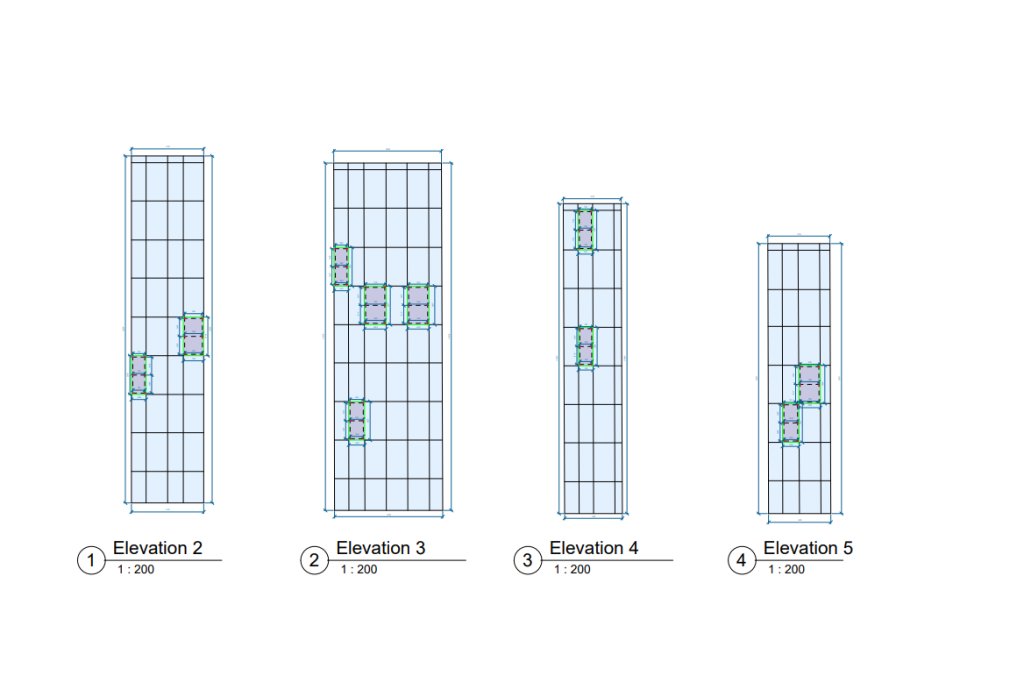

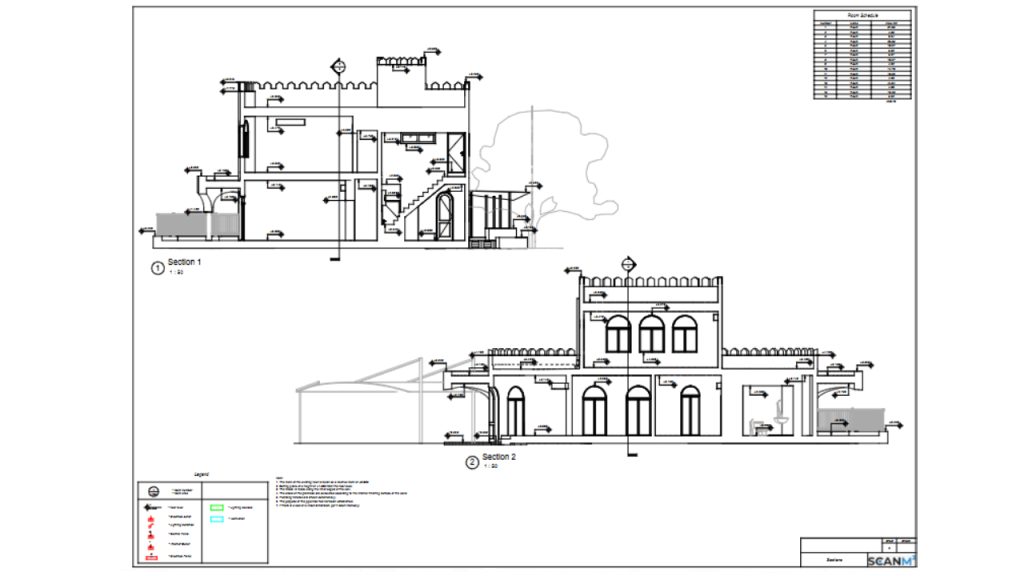

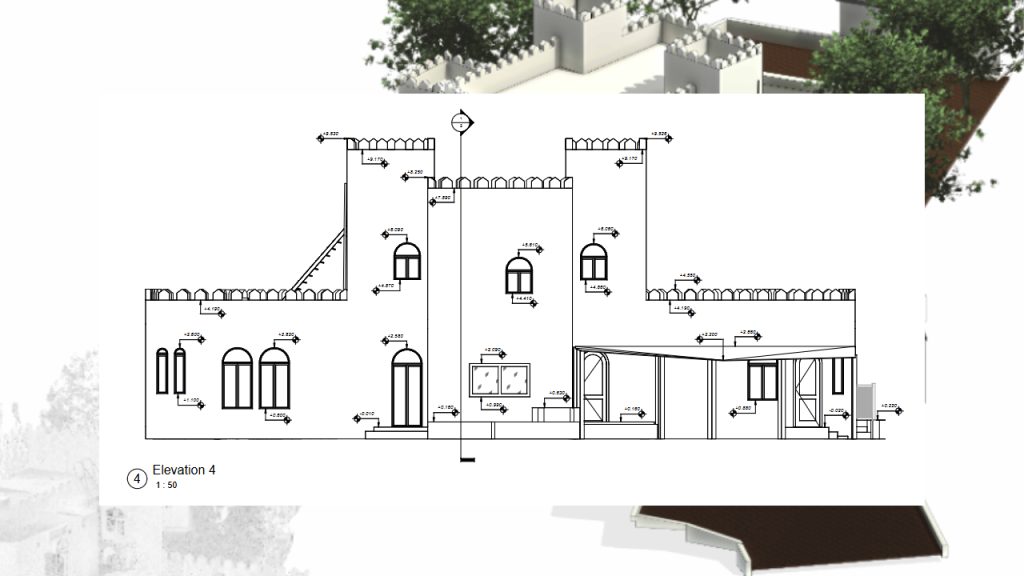

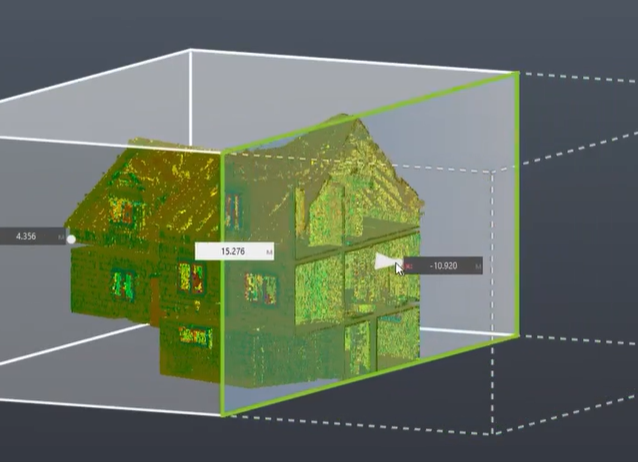

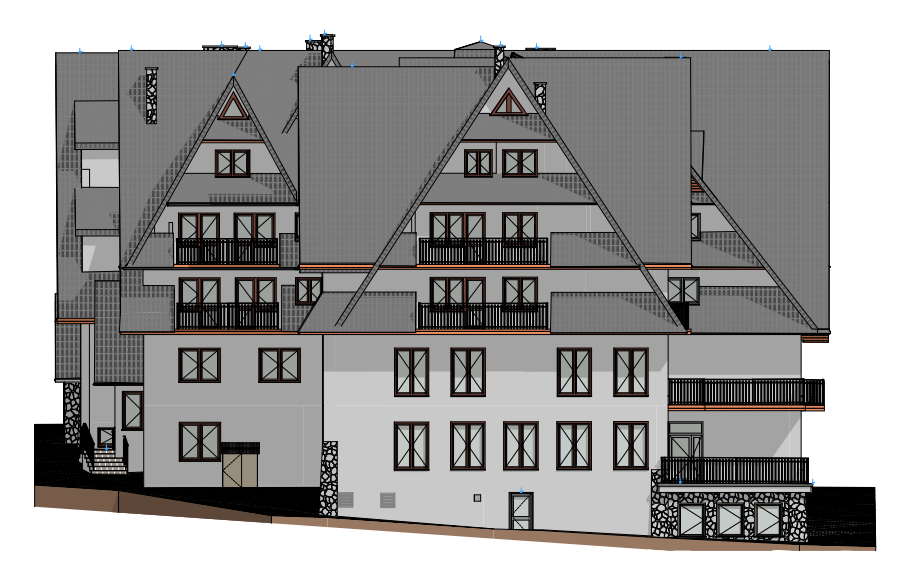

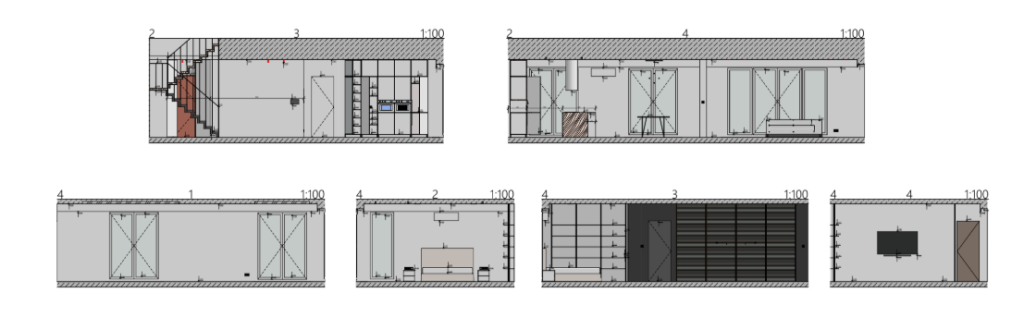

Deliverables You Should Expect from a 3D Scanning Company in NYC

Before hiring a laser scanning company, clarify exactly what you will receive. Deliverables should align with your project workflow.

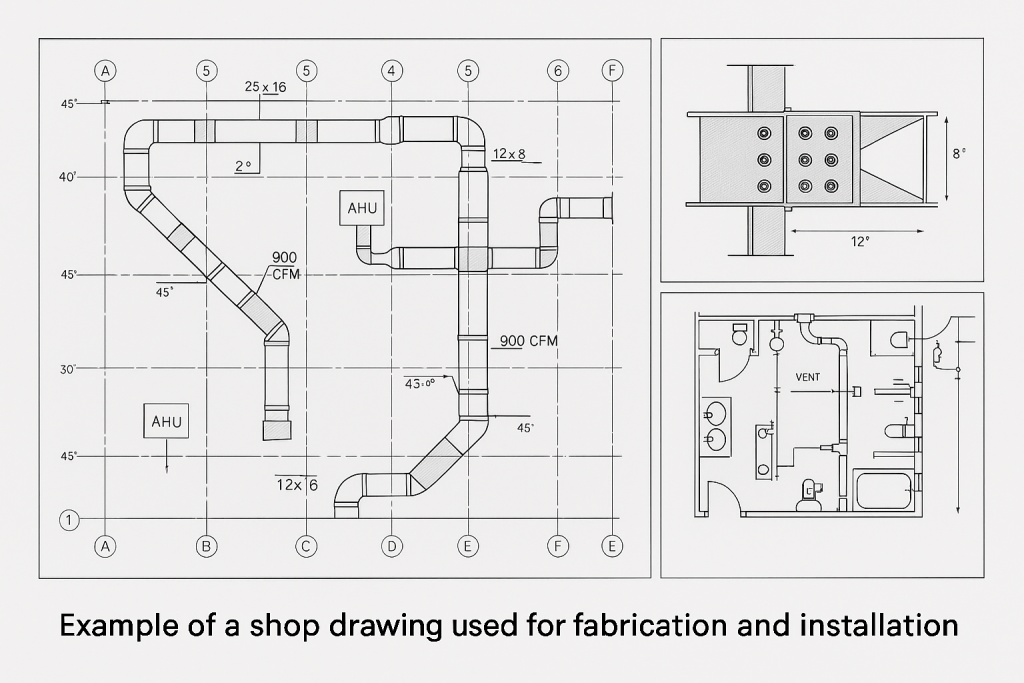

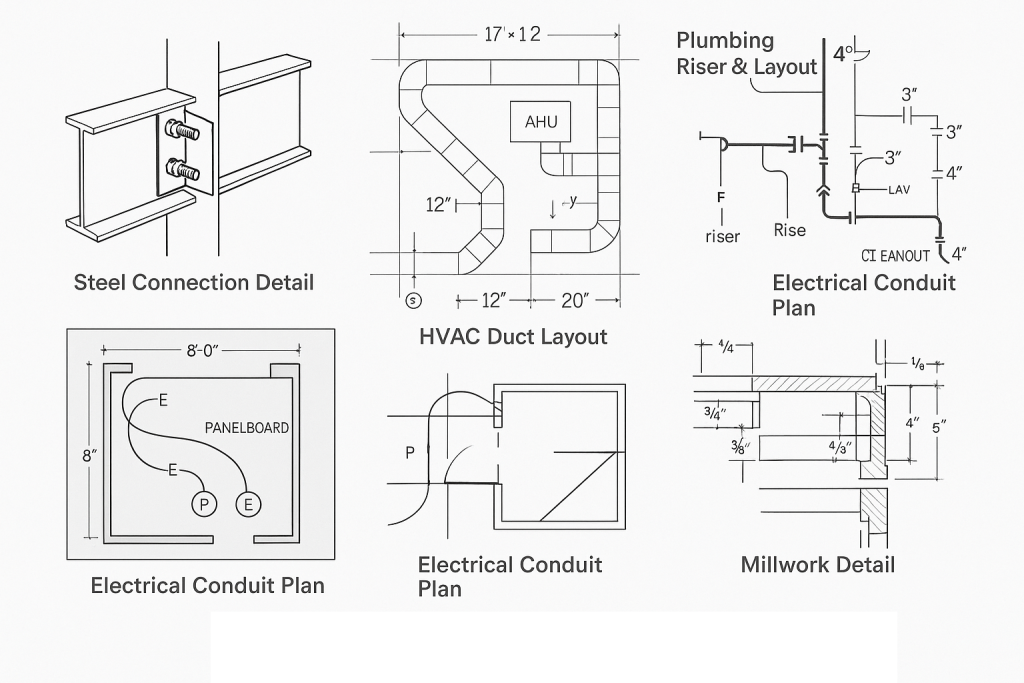

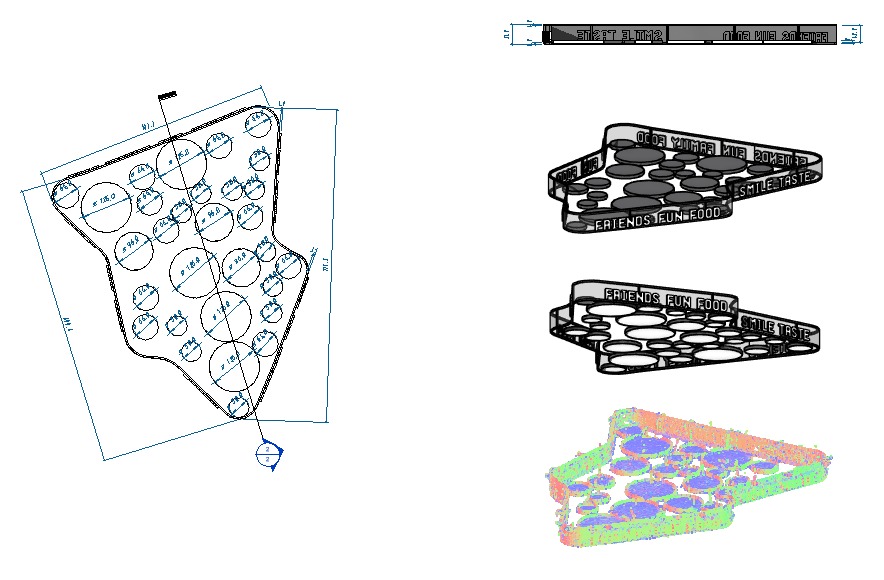

Common deliverables include:

- Registered point cloud files (.RCP, .E57, .LAS)

- 2D CAD drawings

- BIM-ready Revit models

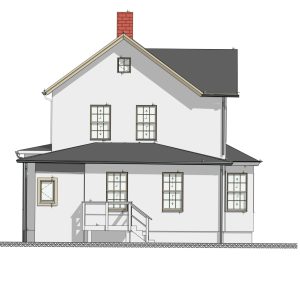

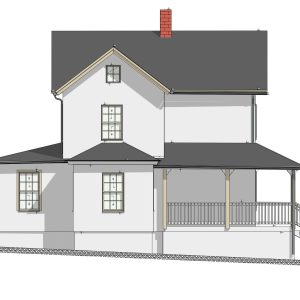

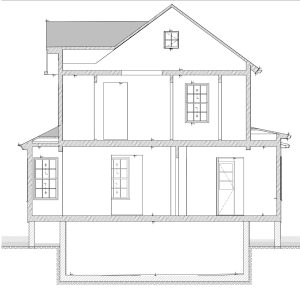

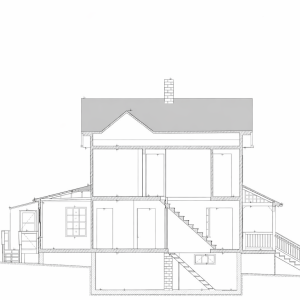

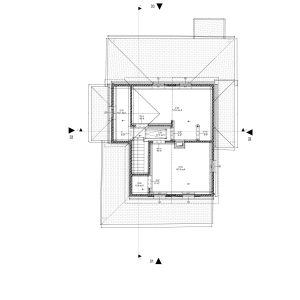

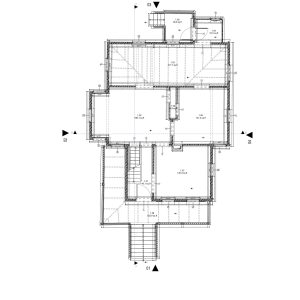

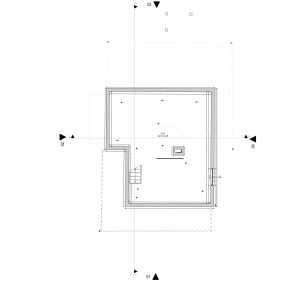

- Floor plans, sections, elevations

- Clash detection-ready models

- As built documentation packages

Here’s a comparison of typical deliverable levels:

| Service Level | Point Cloud | 2D CAD | BIM Model | Clash Detection Support |

| Basic Scan | ✔ | ✖ | ✖ | ✖ |

| Documentation Package | ✔ | ✔ | ✖ | ✖ |

| Scan to BIM | ✔ | ✔ | ✔ | ✔ |

If you’re evaluating the best laser scanning company, look for flexibility — the ability to scale deliverables depending on renovation, retrofit, or new construction scope.

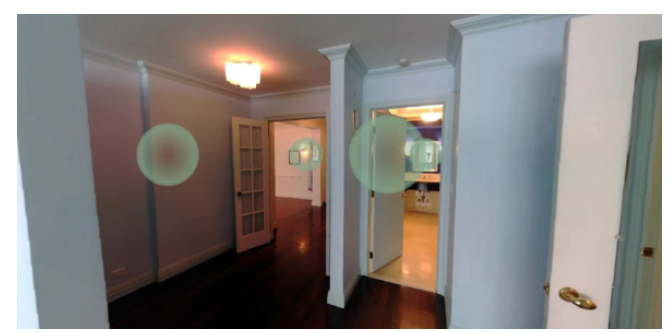

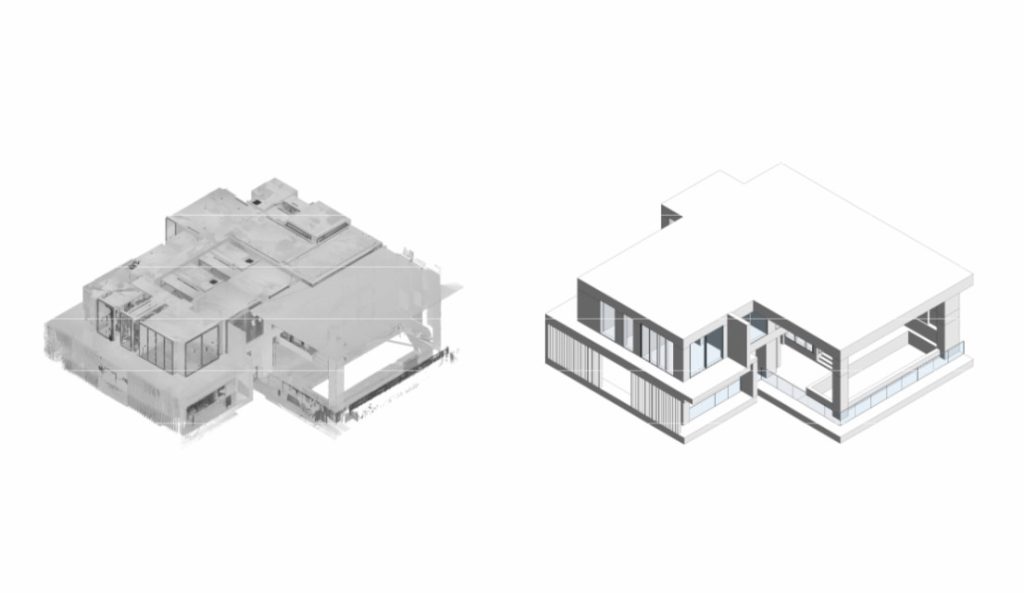

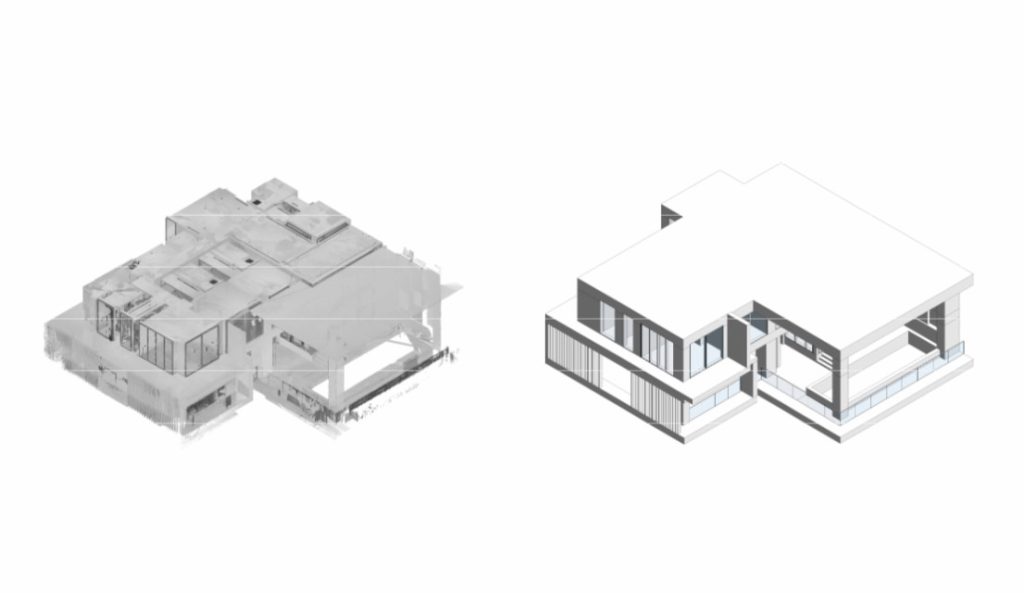

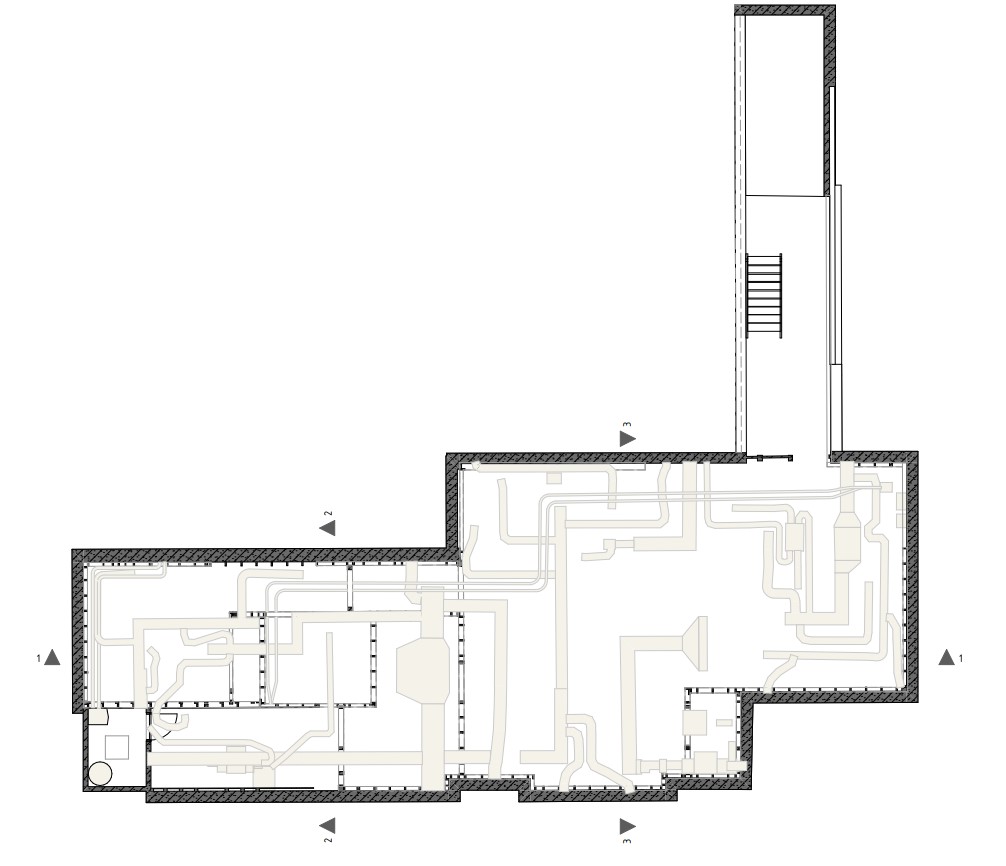

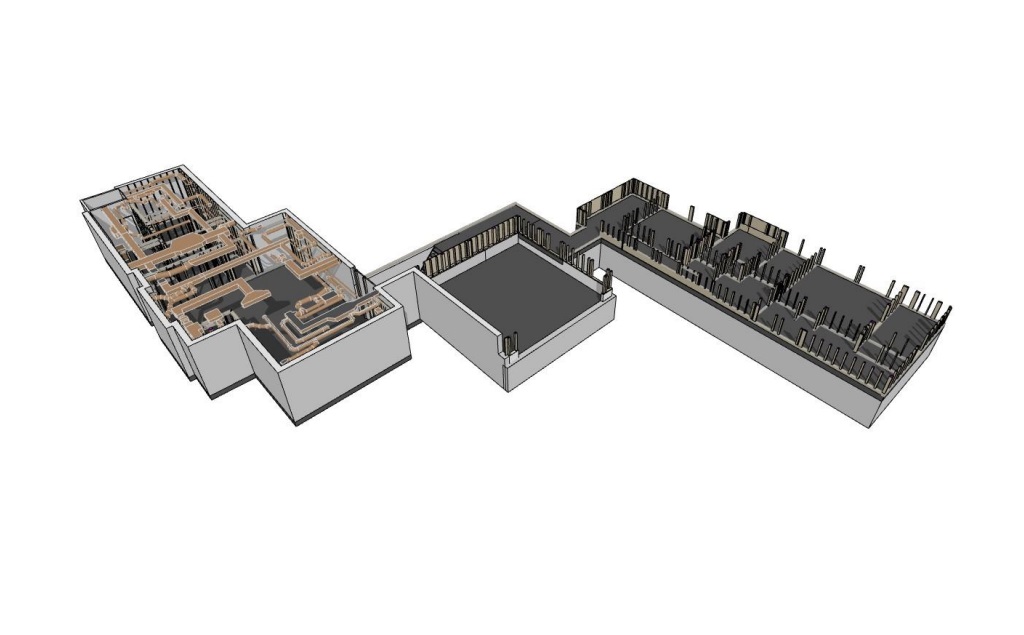

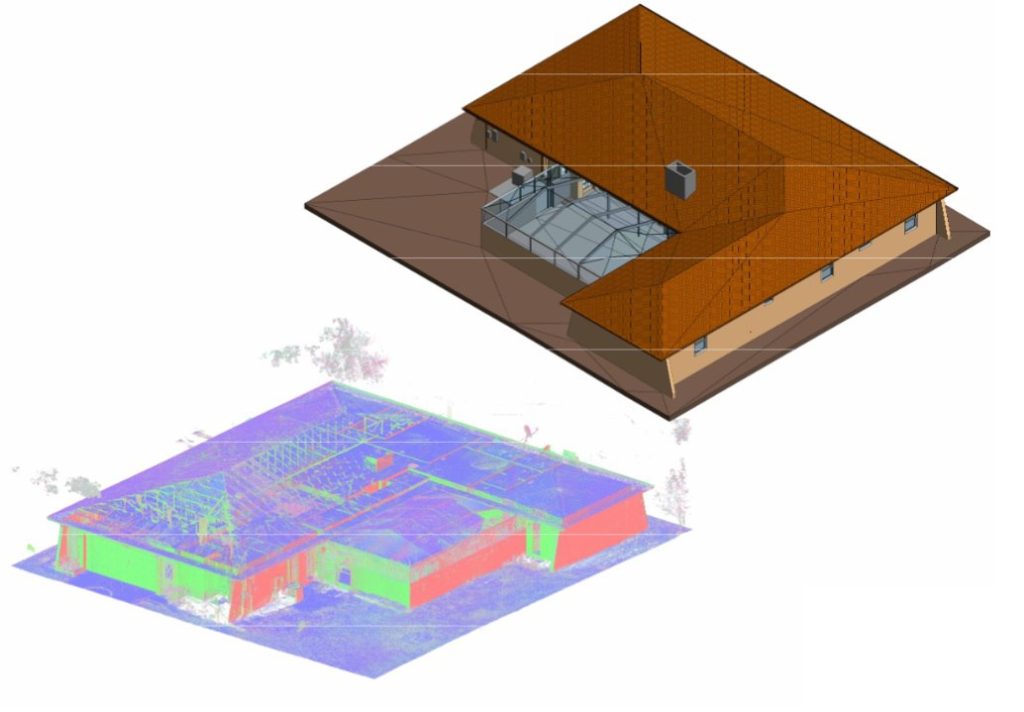

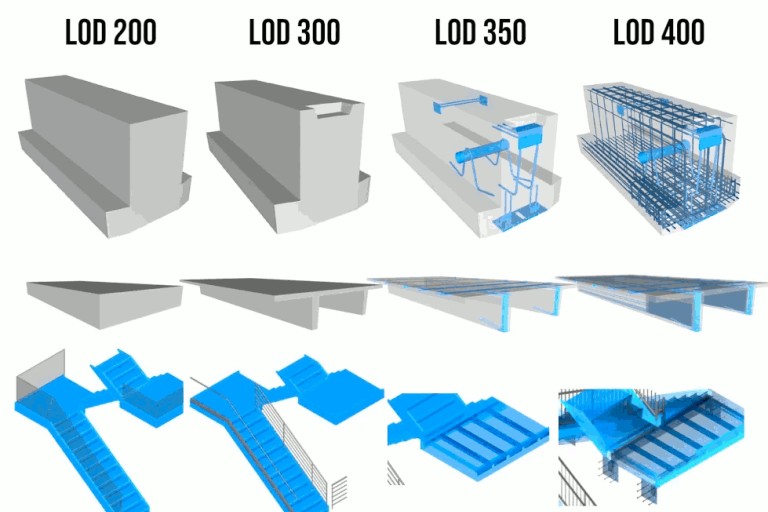

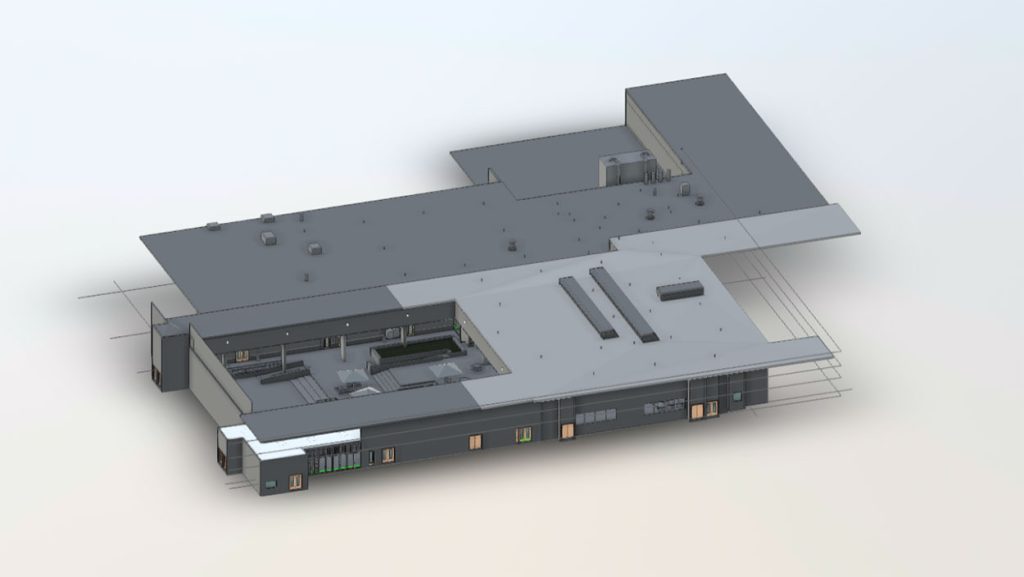

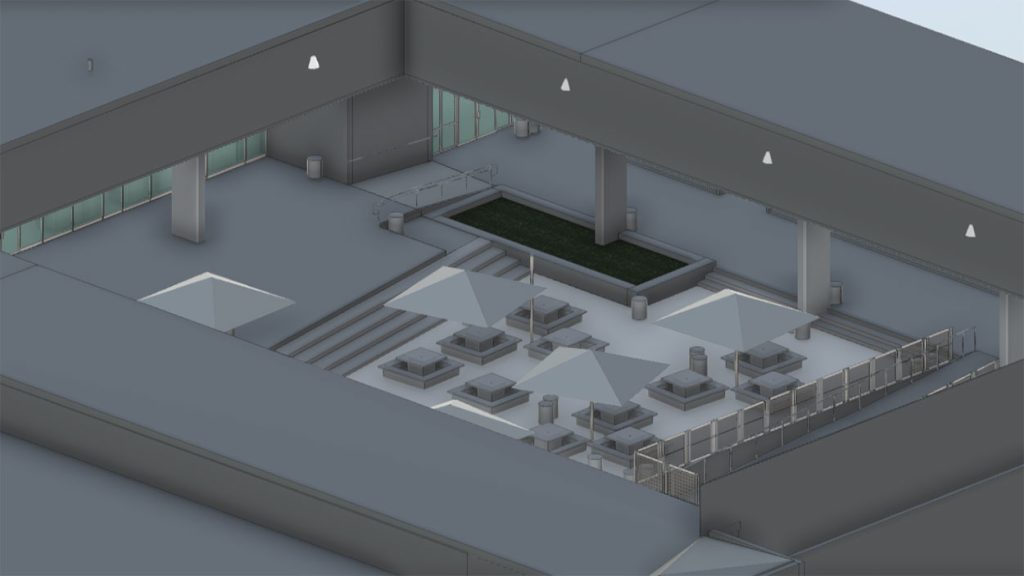

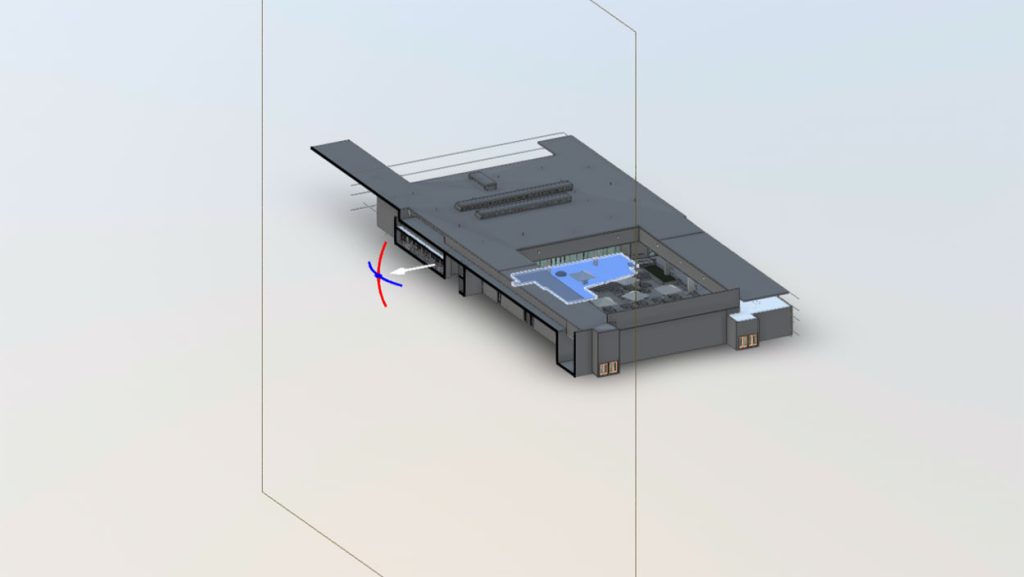

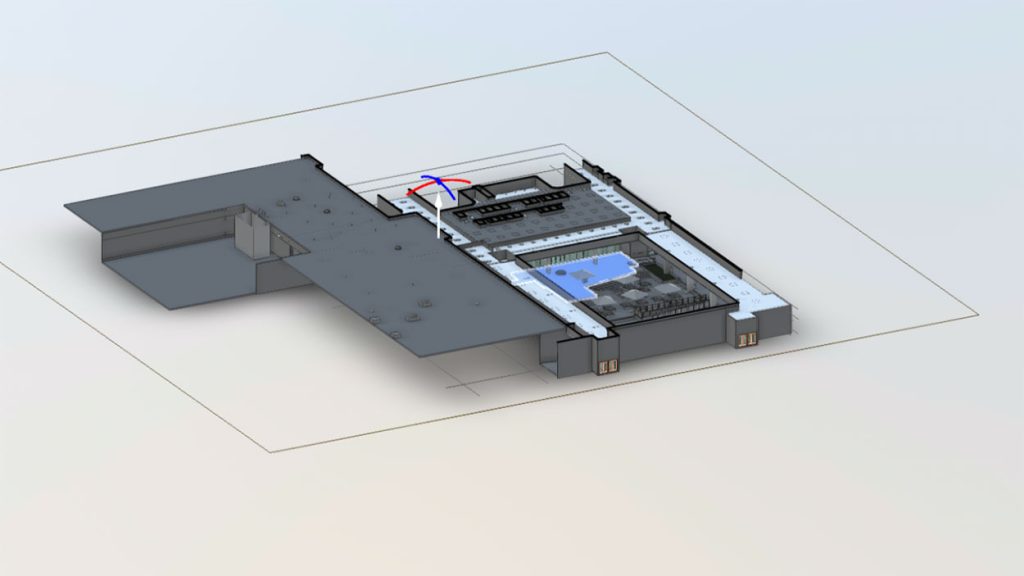

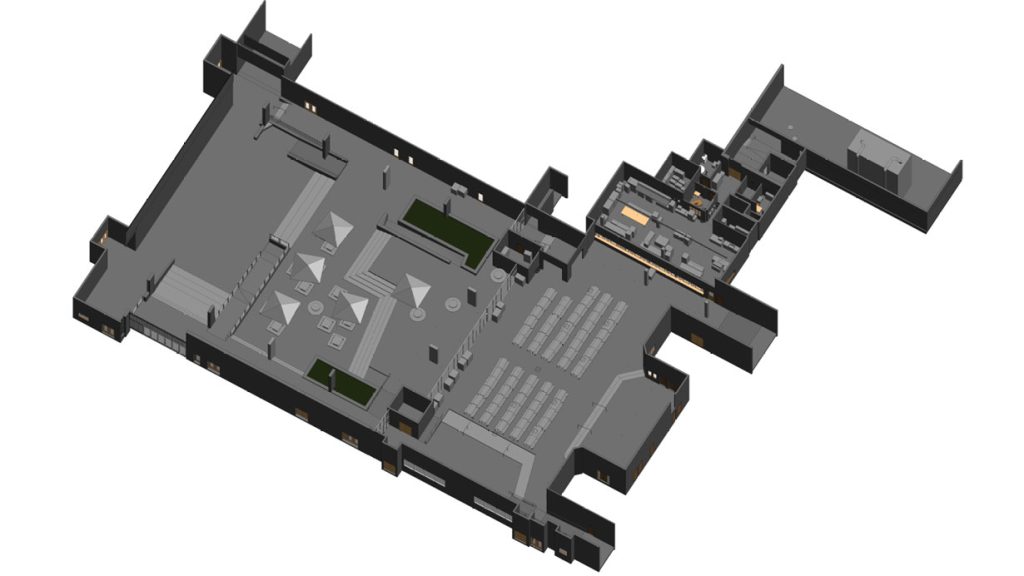

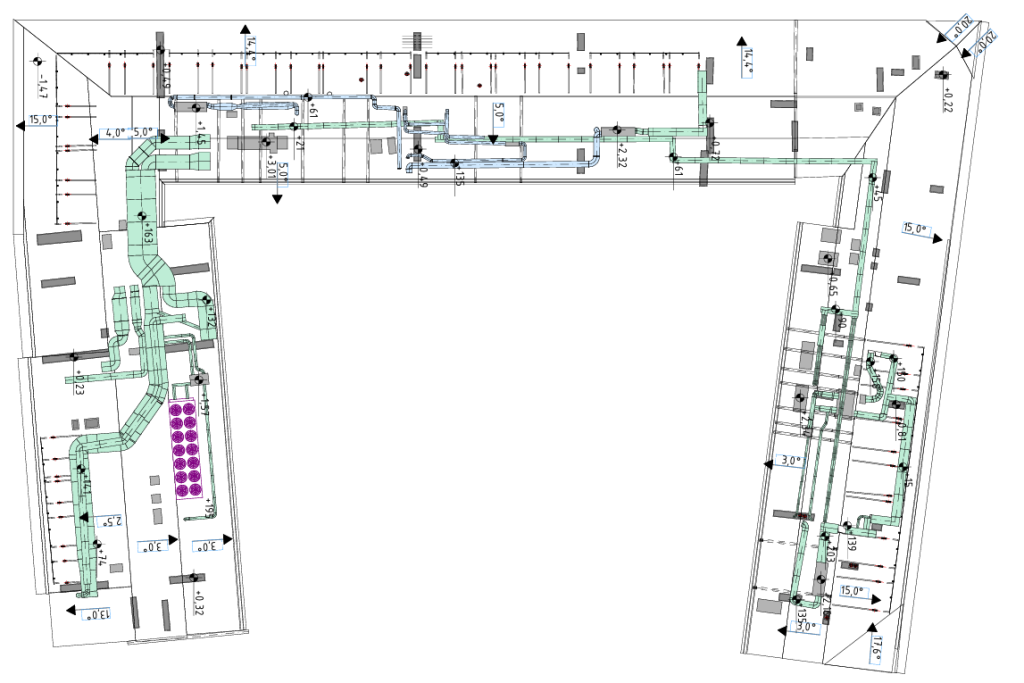

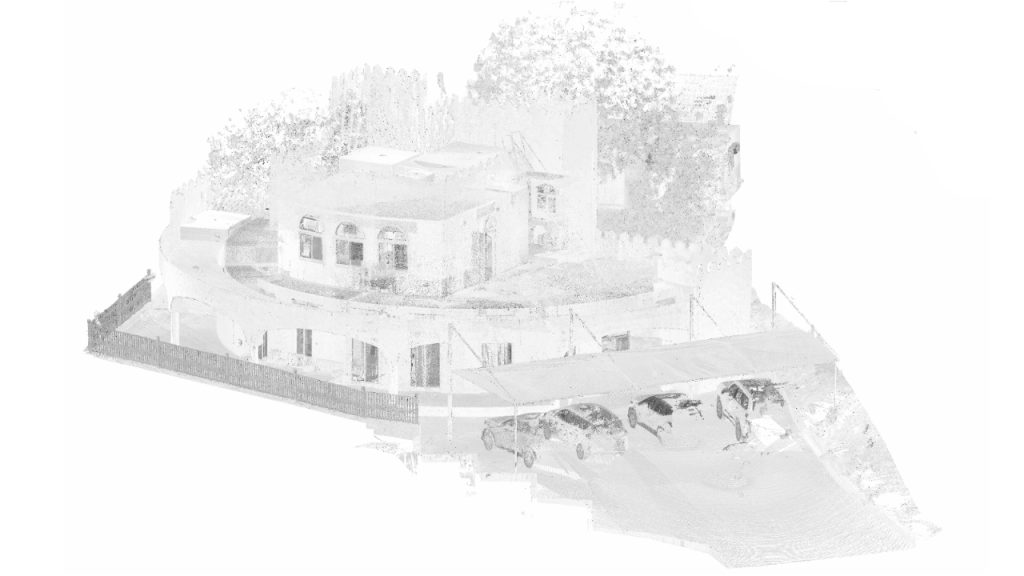

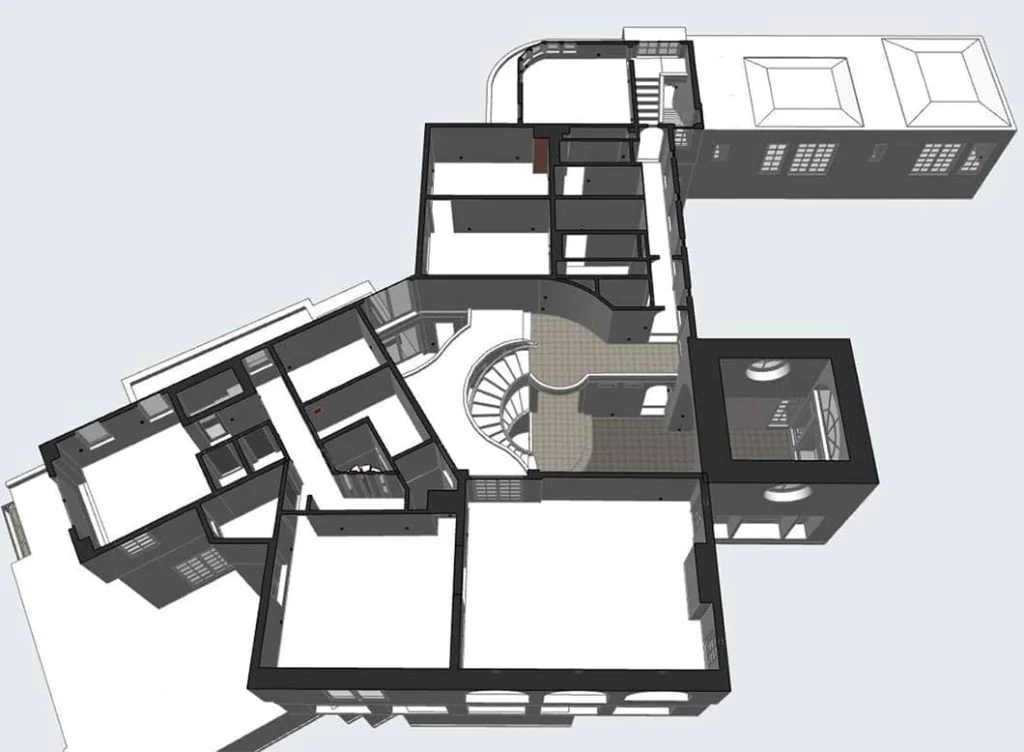

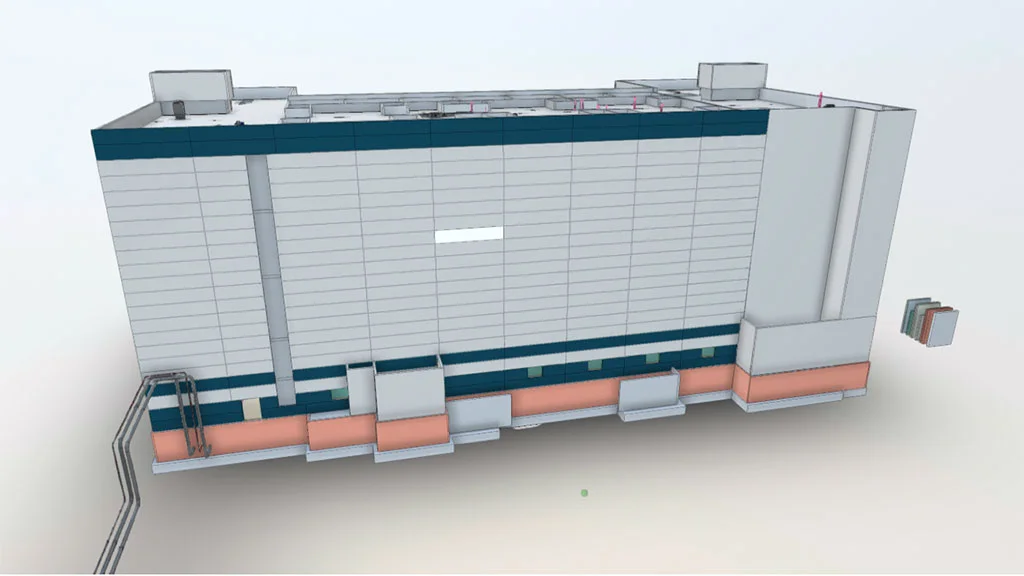

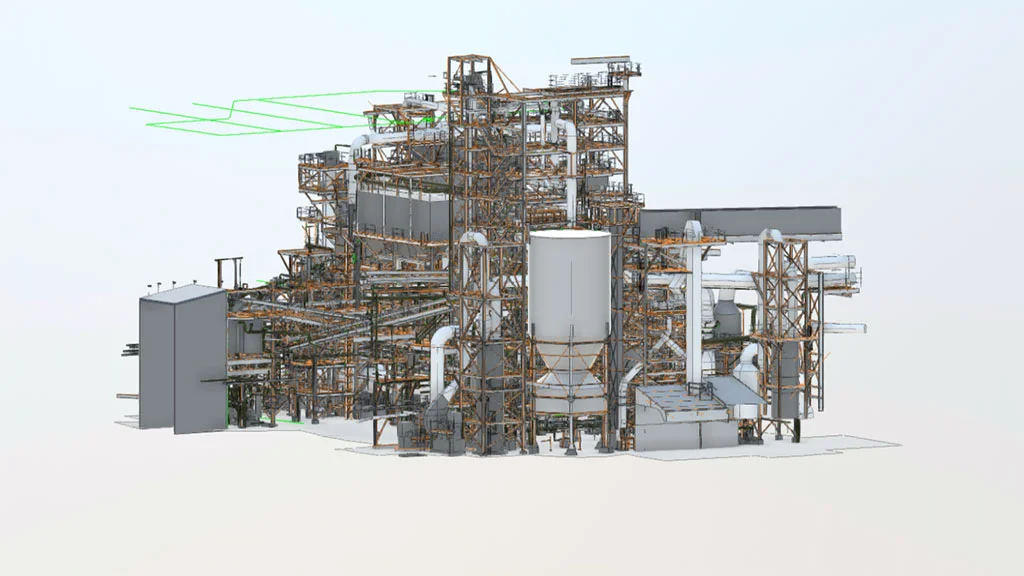

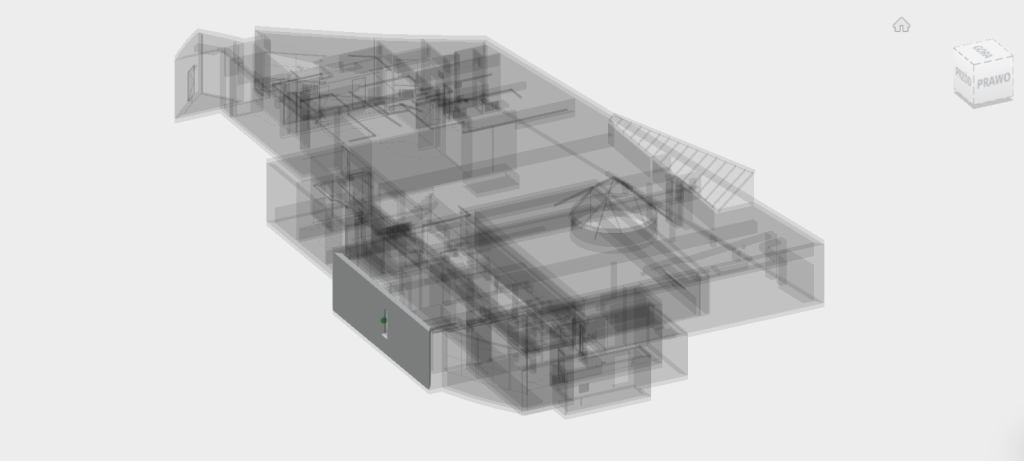

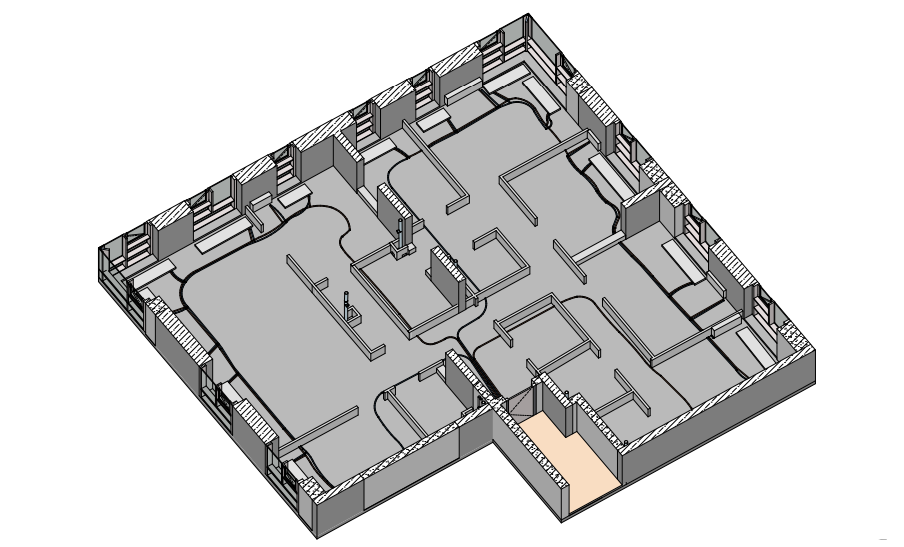

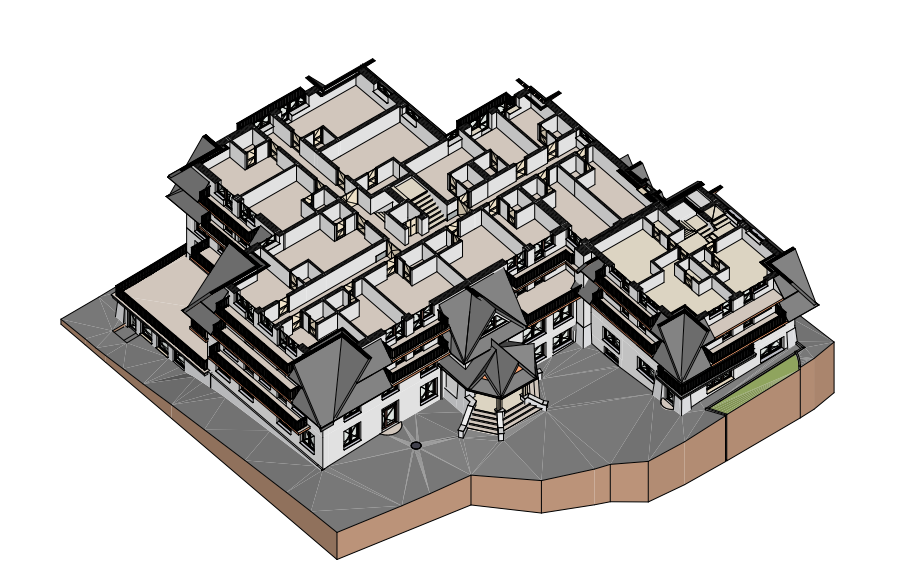

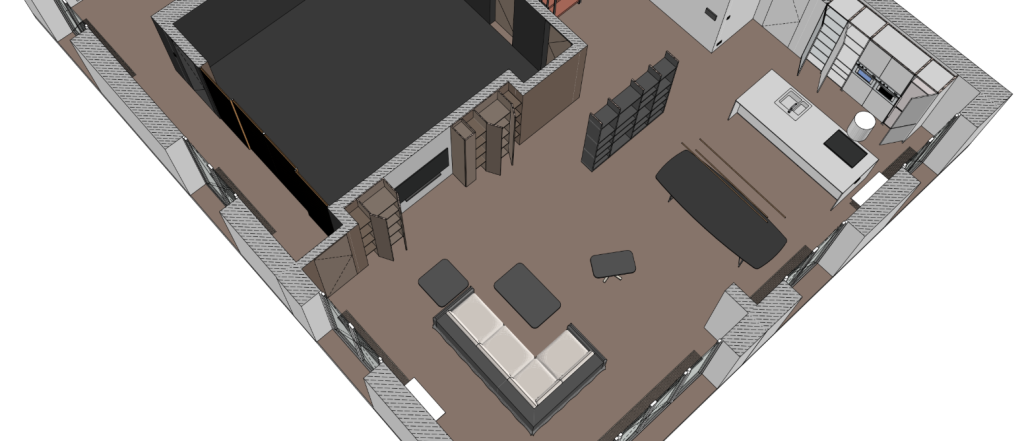

Role of Scan to BIM in Renovation Projects in New York City

Renovation projects in older New York buildings often suffer from undocumented changes and outdated drawings.

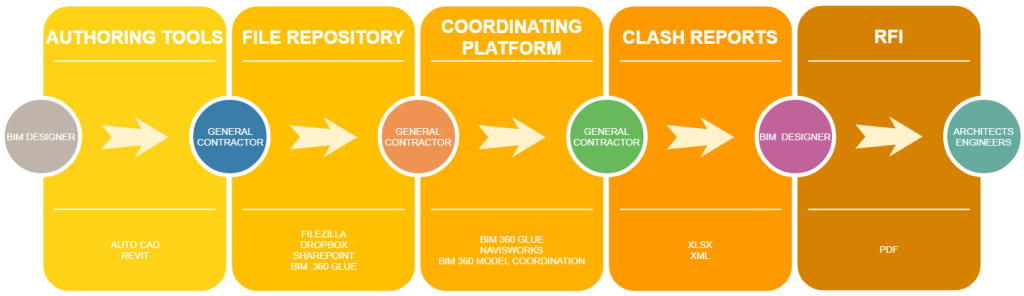

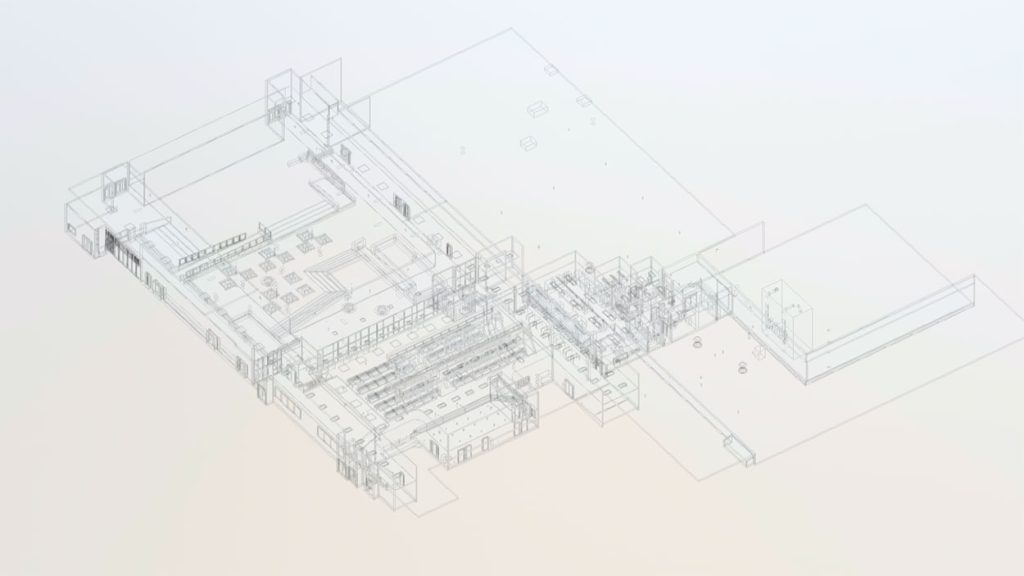

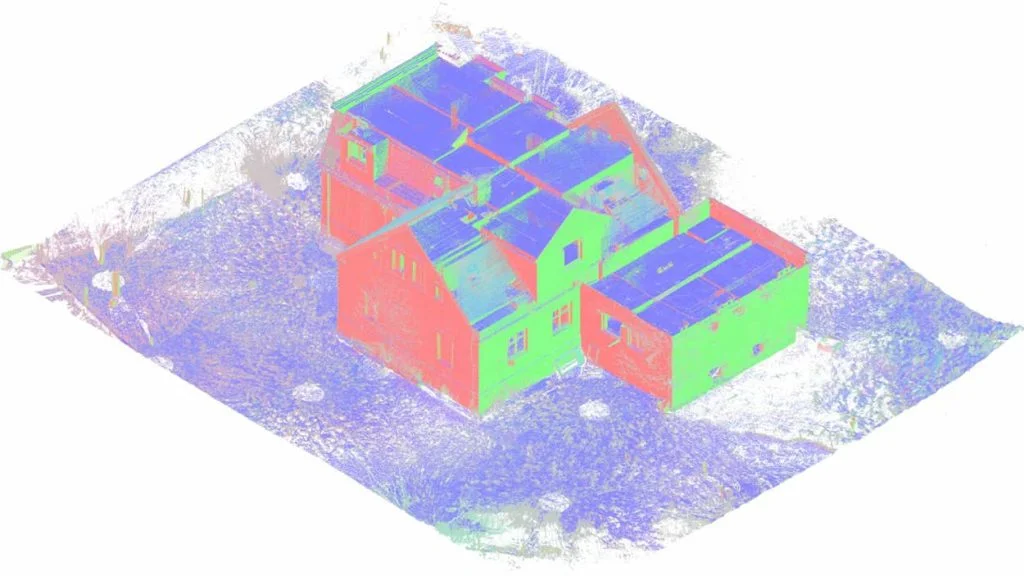

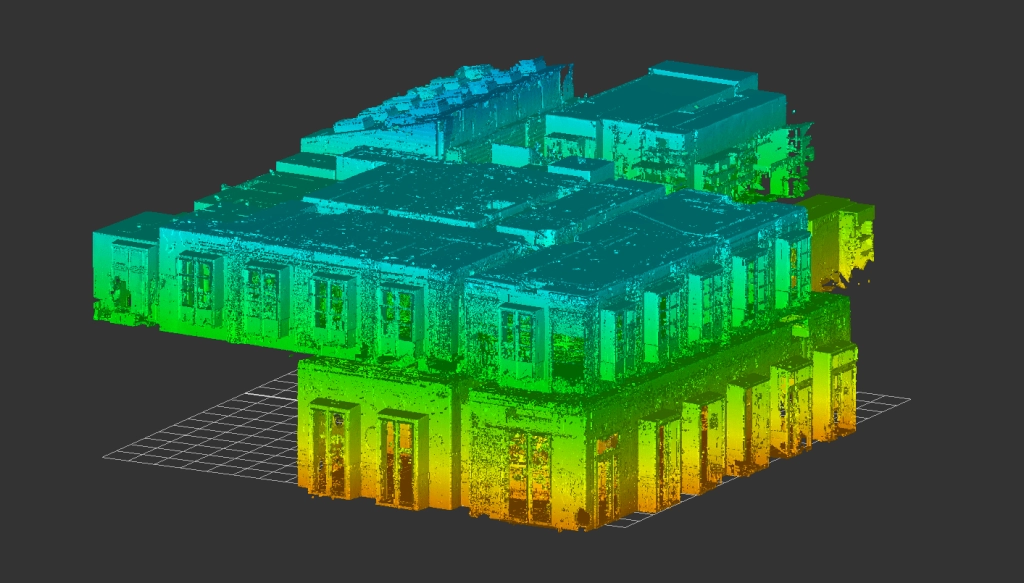

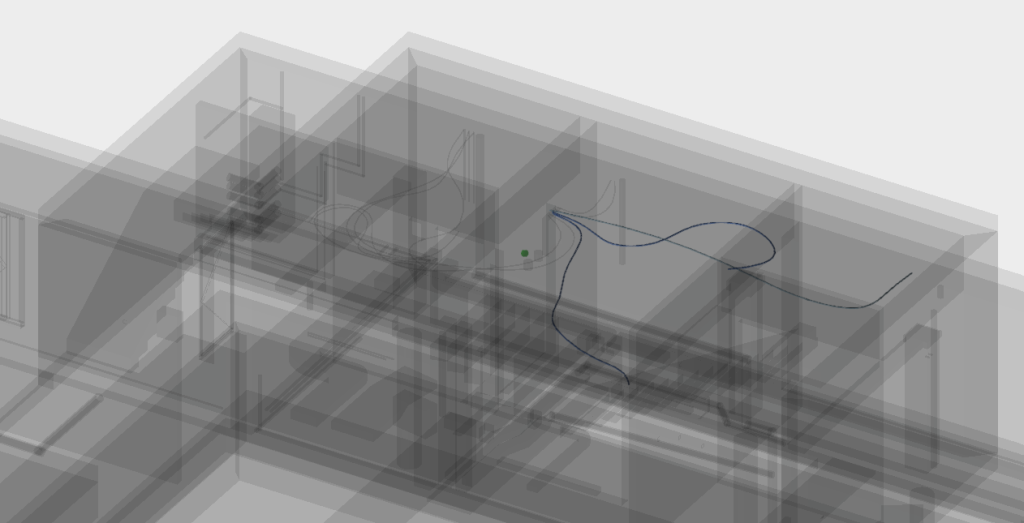

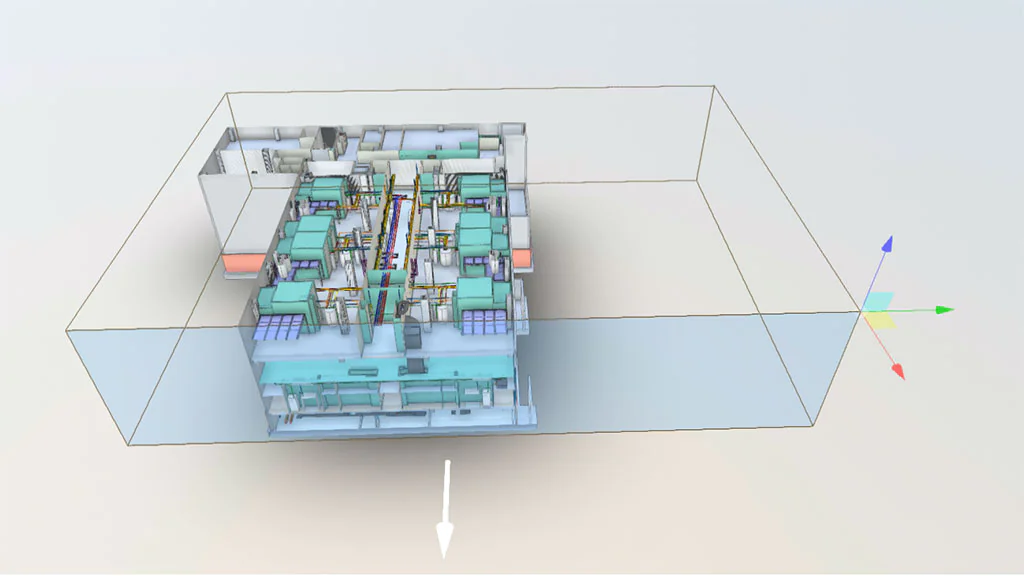

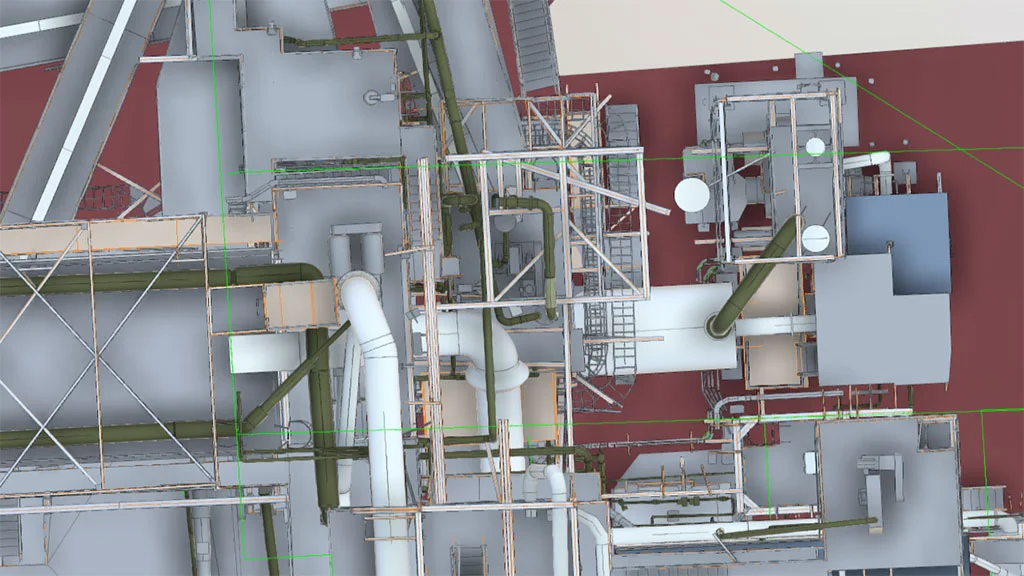

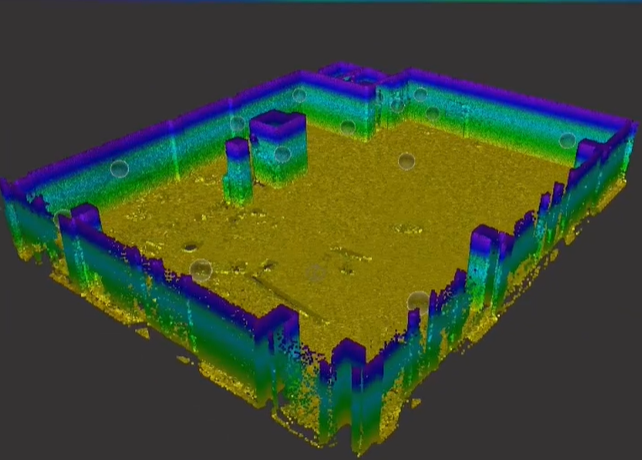

A structured scan to BIM workflow converts raw point cloud data into an intelligent 3D model that includes:

- Walls, slabs, columns

- Structural framing

- MEP systems

- Ceiling and façade elements

For adaptive reuse and interior renovations, scan to BIM reduces unknown conditions and supports design coordination.

When selecting a laser scanning company, confirm whether modeling is done in-house or outsourced — this directly impacts quality control and turnaround time.

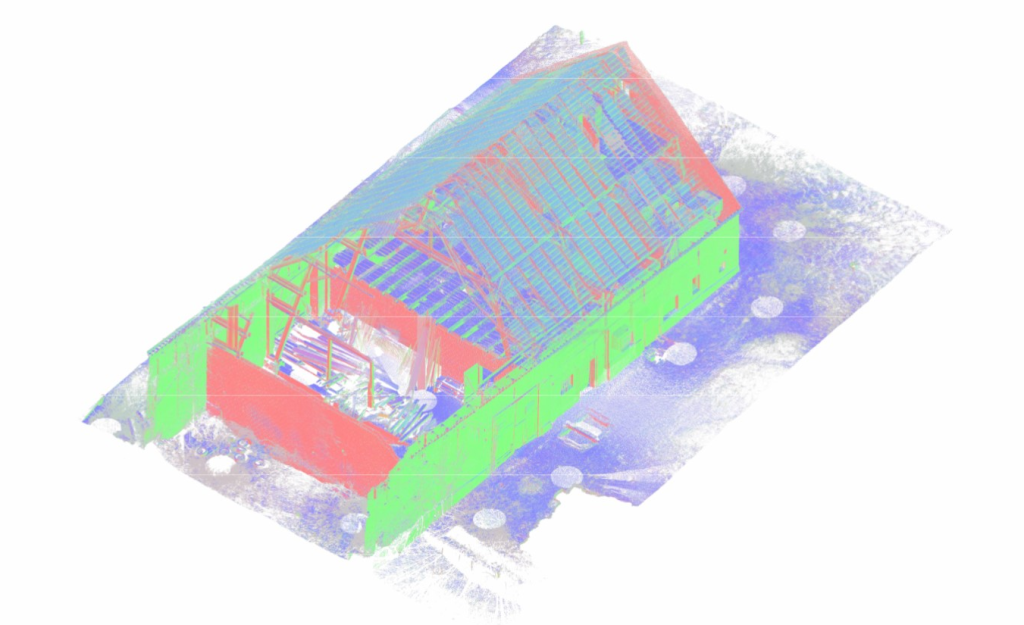

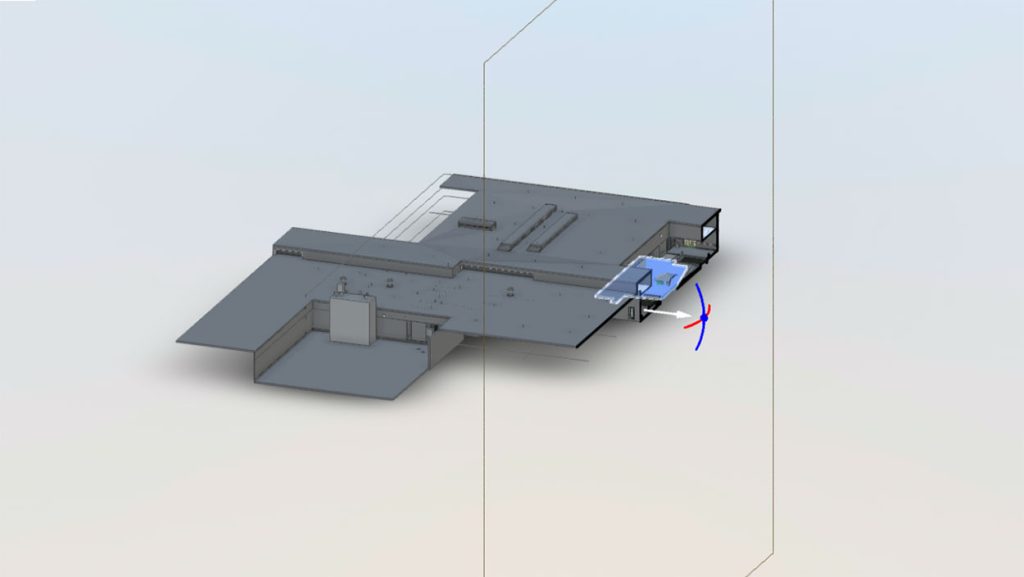

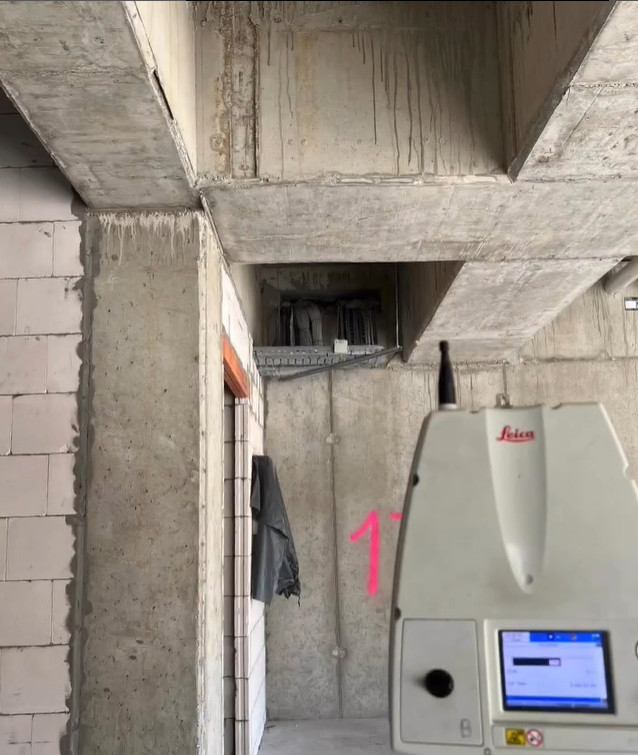

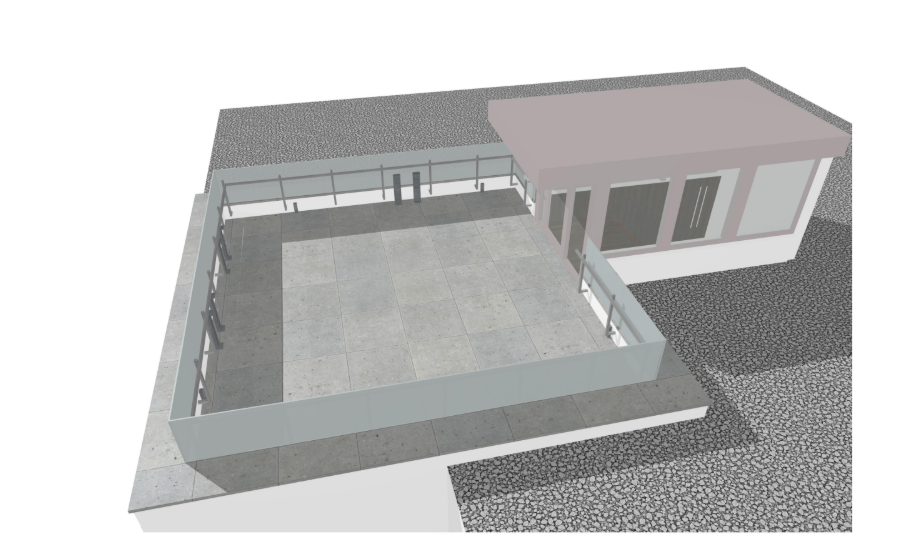

Laser Scanning for Retrofit and Construction Projects in NYC

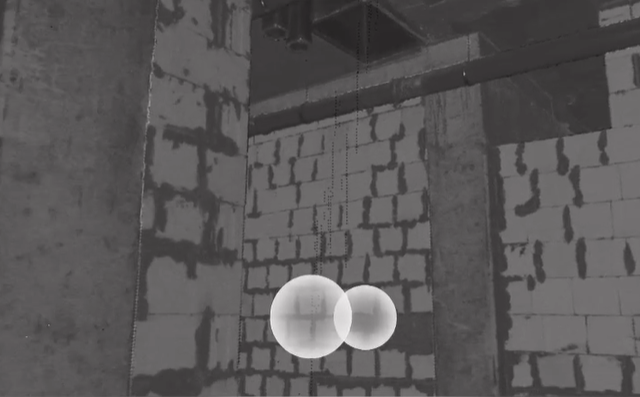

Retrofit projects are particularly sensitive to dimensional accuracy. In dense environments like NYC, space constraints make traditional measurement methods unreliable.

Laser scanning supports:

- HVAC retrofits

- Electrical upgrades

- Plumbing replacements

- Structural reinforcements

- Façade replacements

Using 3D scanning in NYC allows contractors to detect interferences before fabrication begins. This significantly reduces change orders and field conflicts.

When hiring a laser scanning company, ask about their experience with retrofit sequencing and coordination workflows.

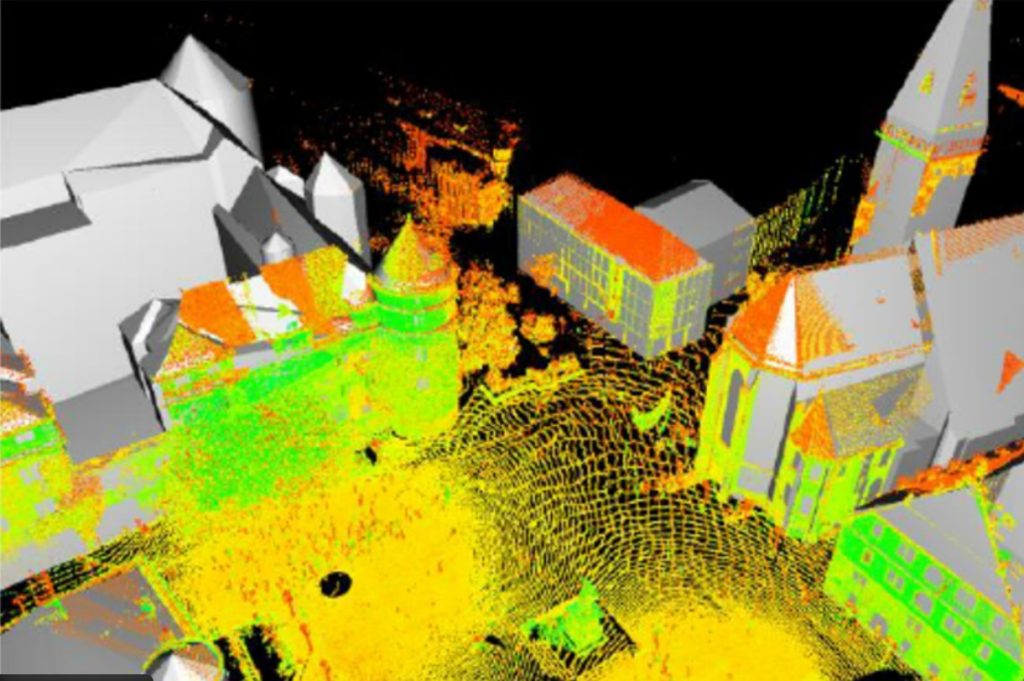

Equipment Used by Professional Laser Scanning Companies in New York

Technology directly affects data quality and speed. When comparing laser scanning companies, inquire about equipment types.

Common professional systems include:

- Terrestrial laser scanners (high-accuracy building scanning)

- Mobile mapping systems (faster coverage for large spaces)

- Drone-based LiDAR (roof and façade capture)

A reliable provider offering building scanning services NYC should:

- Use industry-grade equipment

- Maintain regular calibration

- Provide scan reports

- Follow strict data management protocols

Choosing a laser scanning provider based solely on price can result in lower-density scans and reduced model accuracy.

How Long Does Building Scanning Take in NYC?

Scanning duration depends on:

- Building size

- Complexity of MEP systems

- Access restrictions

- Required deliverables

Here is a general timeframe estimate:

| Building Size | On-Site Scanning Time | Modeling Time (Scan to BIM) |

| 10,000–20,000 sq ft | 1–2 days | 1–2 weeks |

| 50,000 sq ft | 3–5 days | 2–4 weeks |

| 100,000+ sq ft | 1–2 weeks | 4–8 weeks |

When asking how to choose a 3D scanning company , timeline transparency is a key indicator of professionalism.

What Affects the Cost of Laser Scanning in New York City?

Several factors influence pricing:

- Project size

- Required accuracy level

- Deliverable complexity

- Site accessibility

- Union labor requirements

- Night/weekend work

Cost comparison checklist when selecting a laser scanning company:

- Is registration included?

- Is modeling included?

- Are revisions included?

- Is travel billed separately?

- What file formats are delivered?

The best 3D scanning company will provide a detailed scope breakdown rather than a lump-sum estimate.

Questions to Ask Before Hiring a Laser Scanning Company in NYC

If you’re at the final stage of choosing a laser scanning provider, ask these questions:

- What commercial projects have you completed in New York City?

- What accuracy tolerance do you guarantee?

- Do you provide in-house scan to BIM services?

- What quality control procedures do you follow?

- Can you share sample deliverables?

- How do you handle data storage and backups?

- What is your turnaround time?

Understanding what to look for in a laser scanning company helps reduce risk and ensures alignment with construction goals.

Final Thoughts: Making the Right Decision

Learning how to choose a 3D scanning company requires evaluating experience, accuracy standards, technology, deliverables, and workflow integration.

Whether you’re comparing laser scanning companies or preparing for a major renovation, the right partner will provide:

- High-quality point cloud data

- Reliable as built documentation

- Structured scan to BIM workflow

- Clear pricing and timelines

When hiring a laser scanning company for projects in New York City, prioritize technical capability and construction experience over lowest cost. The long-term savings in avoided rework and coordination conflicts will far outweigh the initial investment.

FAQ

How do I choose the best 3D scanning company?

When choosing a laser scanning provider, evaluate their experience with commercial projects, accuracy standards, equipment quality, scan to BIM capabilities, and deliverable transparency. The best 3D scanning company will clearly define tolerances, timelines, and data formats before starting the project.

What should I look for in a laser scanning company?

Look for proven experience in architectural, structural, and MEP scanning, high-accuracy equipment, quality control procedures, and the ability to provide point cloud data and as built documentation that integrate with your BIM workflow.

How much does laser scanning cost in New York City?

The cost of laser scanning in New York City depends on building size, required accuracy, complexity of deliverables, and whether scan to BIM modeling is included. Larger commercial projects typically require custom pricing based on scope.

What deliverables should a professional laser scanning company provide?

A professional provider should deliver registered point cloud files, 2D CAD drawings (if required), BIM-ready models, and complete construction documentation packages depending on your project needs.

How long does 3D building scanning take?

Scanning time depends on building size and complexity. Small projects may take 1–2 days onsite, while large commercial buildings may require a week or more, followed by modeling time for scan to BIM deliverables.

Is scan to BIM necessary for renovation projects?

Yes. For renovation and retrofit projects, scan to BIM reduces risk by converting existing conditions into accurate digital models, helping teams avoid design conflicts and costly change orders.